- Moisture

- Commercial

- Blog

Using WUFI® as a moisture management design tool

Blog in Brief

Although buildings can face a wide range of regional conditions, there are a few main design strategies used to create wall systems. Two of these strategies look to allow moisture to flow through the wall assembly or seek to provide a control layer for condensation. However, it can be challenging to account for all the elements that a wall system will face during its lifespan, especially in areas where climate changes significantly throughout the year. Using a predictive tool like WUFI® – short for Wärme und Feuchte instationär – software allows designers to make more informed design choices by providing a realistic depiction of hygrothermal behavior, how heat and moisture are likely to move through multi-layer building components in an area over time.

Using WUFI® as a Moisture Management Design Tool

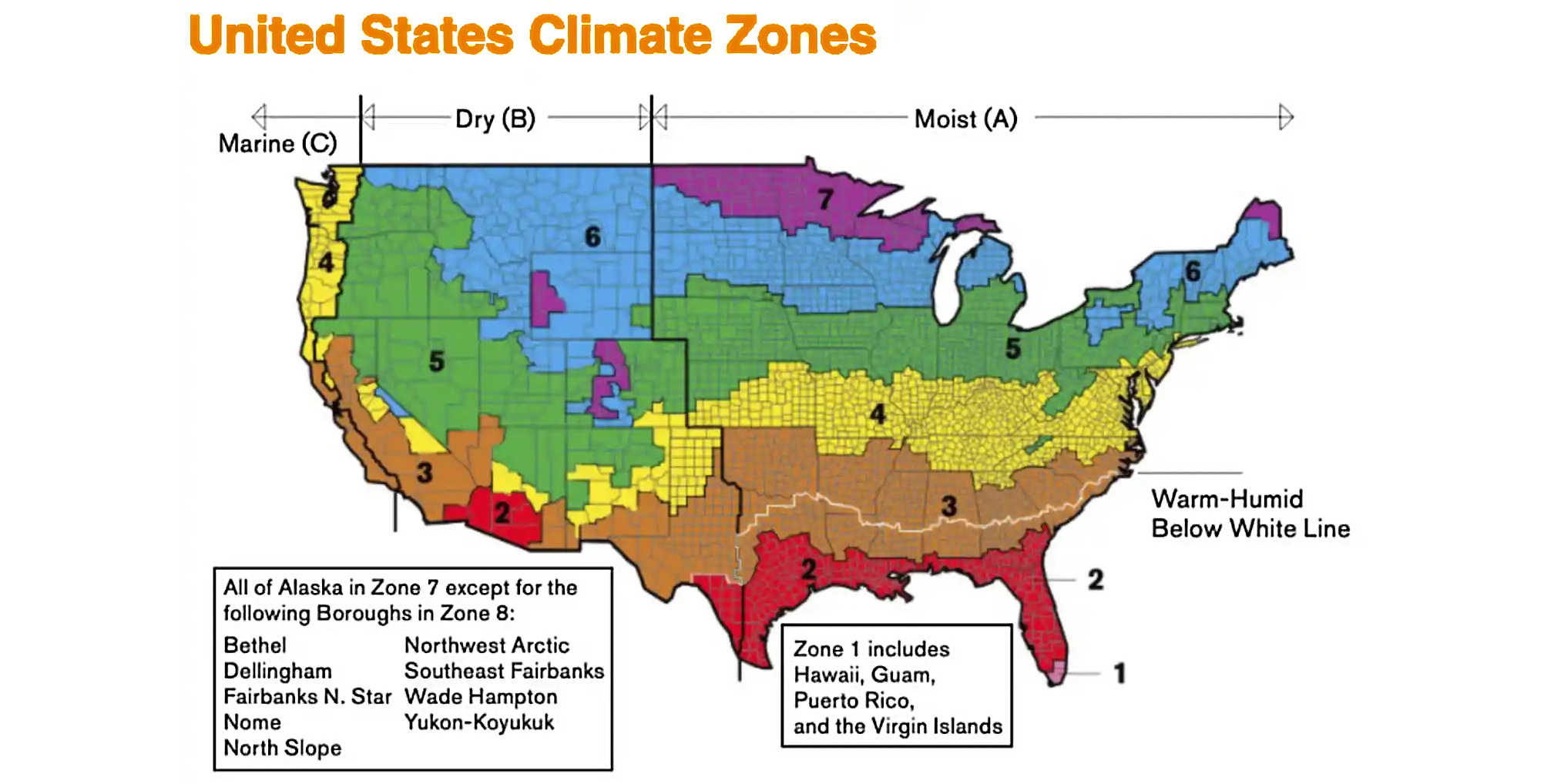

Across the U.S., differences in climate zones play a role in the type of moisture control required when designing wall systems because not every region has the same conditions, humidity or temperature range. For example, what is needed to protect a building from winter in upstate New York isn’t the same as what is needed to address February conditions in Fort Lauderdale, Florida, just as July in Tucson, Arizona and Seattle, Washington may not prompt the same requirements to keep a building dry and at a comfortable temperature.

Map of the United States Climate Zones. Source: 2012 IECC - International Energy Conservation Code

Across the country, there are two commonly used design strategies when planning wall assemblies to provide moisture control. These include flow-through designs that let water vapor pass through both sides and designs using a control layer that prevents moisture from moving in a specific direction. The location of the moisture control layer tends to be dictated by climate – essentially, where the layer goes is based on an understanding of if heating or cooling the building will be more important. Another version of the control layer system looks to control the surface temperature where condensation could occur, typically by installing an additional element like continuous insulation.

Flow-through vapor control design strategy

One wall design strategy intended to account for moisture movement is the flow-through wall plan. The intention is to have an assembly that is vapor open on the interior and exterior, and which uses vapor open insulation along with a vapor permeable air barrier.

This type of wall assembly works well in many regions as it supports the movement of moisture and prevents it from being trapped. However, there are several elements to consider when creating these assemblies based on materials and weather, including:

- Exterior cladding: Needs to be selected carefully so it won’t slow vapor movement.

- Interior paint and finishing selection: Low-perm paint, vinyl wall coverings or paint buildup over time can alter how well vapor moves and inhibit wall drying on the interior side.

- Regions with cold and damp winters: Interior moisture may build up but not be able to leave.

- “Reservoir” cladding combined with a semi-permeable water control material: The interaction of these materials may push water into the wall’s interior and may create problems from condensation.

Control layer vapor control design strategy

A second wall design strategy intended to account for moisture movement is the control layer wall plan. Wall assemblies can be created with a control layer to block movement of moisture vapor. Where the control layer is placed tends to be dictated by moisture and heat. These tend to be popular in regions with cold winters. Another version of this type of assembly looks to raise the wall’s temperature to prevent condensation using continuous insulation. There are several elements to consider when creating these assemblies, including:

- Overly impermeable systems: If insulation is placed toward the interior of the wall assembly and is too impermeable, it can delay inward drying and cause problems.

- Internal finishing selection: Paint permeability, layers and internal finishing can alter how these system work.

- “Double vapor retarder” creation: When a vapor retarder is installed, other components of the assembly must be considered to prevent two vapor control layers being installed.

- Severe temperatures: Raising assembly temperatures to prevent condensation works best when the insulated surfaces remain above dewpoint. If insufficient amounts of insulation are used, the system may fail in extreme temperature conditions.

Water vapor management and WUFI®

Although the fundamental principles guiding wall system design appear straightforward, they can be difficult to put into practice because of real-world conditions. A goal of wall assembly design is to keep moisture out; however, assemblies also need to allow for moisture to escape. Designing for both provisions can be challenging, because the most efficient strategies for preventing moisture from moving into a system also tend to trap any water that does enter. This can occur if building materials start out wet because of weather events during construction. Local weather conditions can also add to the challenge of managing moisture. Typically, water vapor will seek to migrate from the warmer side of a wall to the colder side, but, in some climates, it can be hard to judge what side of a wall is more likely to be warm or cold.

Movement patterns can also be influenced by building materials that are absorbent. For example, brick exteriors can hold water following rain and change the wall assembly’s hygrothermal performance, or masonry may function as a hygric buffer, insulating against water shocks.

These factors are among those that need to be understood to design an efficient, effective and long-term functioning wall assembly protected from water damage and local climate. Accounting for these elements is what makes WUFI® shine. The software provides insight into wall system science and analysis that helps cut through all the variables to provide useable information and help guide wall assembly design.

Related Articles

Related Articles

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Jump to a Solution Suite

Jump to a Solution Suite