- Fire

- Commercial

- Blog

Navigating Six Special Conditions in Perimeter Fire Containment System Design

Blog in Brief

When designing a perimeter fire containment system for use in a high-rise structure, there can be several unique considerations that have to be addressed. Planning for special conditions can deliver a system that provides the expected hourly fire rating.

Special conditions may include, but are not limited to:

- Short spandrel heights

- Wider spandrels

- Steel back pan use

- Curved spandrel walls

- Exposed curtain wall anchors at the floor line

In situations where specific solutions have not been made, conditions can be evaluated by the Thermafiber Insolutions® team with recommendations given on a case-by-case basis.

Navigating Six Special Conditions in Perimeter Fire Containment System Design

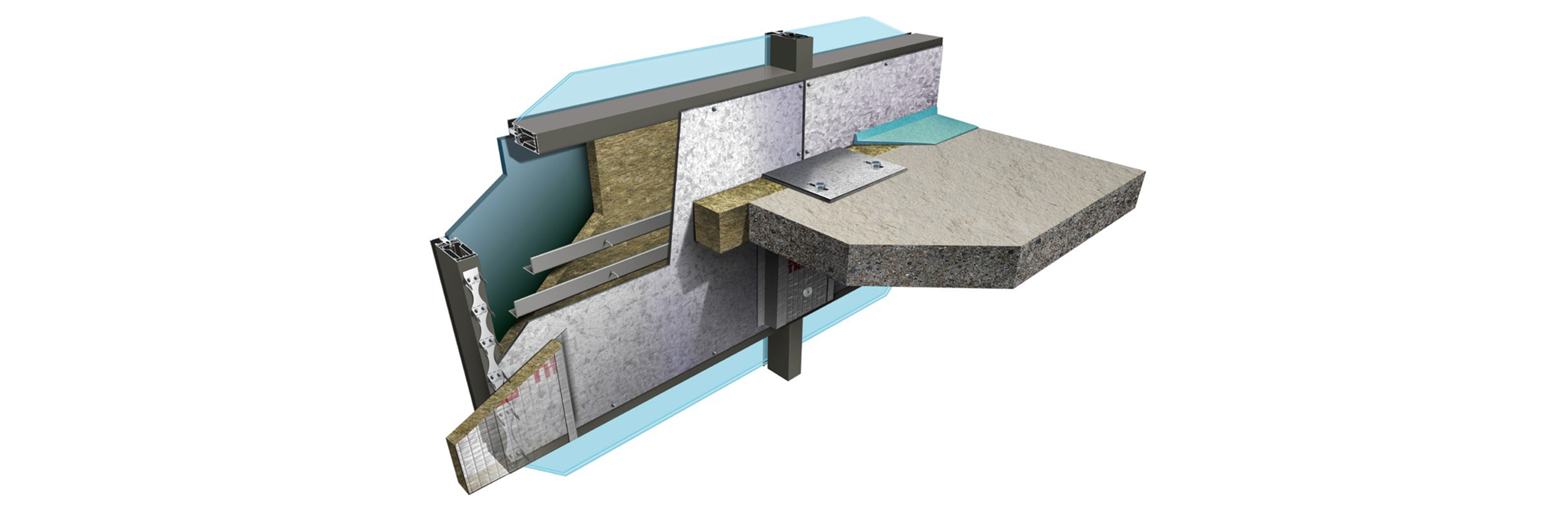

Perimeter fire containment systems are used to help contain a fire to its room of origin. In high-rise structures, these systems create a barrier that is designed to prevent fire and hot gases from moving between floors using the void between the interior side of the curtain wall and edge of the floor slab.

There are situations where special considerations need to be incorporated into the design or installation of perimeter fire containment systems to make sure they work as intended.

Special condition #1: Short spandrel heights

As interest in increasing the amount of vision glass has grown, spandrel height has been shrinking. In the early 1990s, it was not uncommon for spandrels to be 72” tall, although they diminished to 24” by 2012. Today, the shortest spandrel that has been tested and listed is 0”.

PFC system design consideration:

Significant steel reinforcement is needed in these situations; however, there are designs that can be used to provide this reinforcement. Designs created to provide the needed reinforcement establish the desired effect but can be challenging to install.

Special condition #2: Wider spandrels

There is no current process to evaluate wider spandrels given limitations of the test apparatus used in ASTM E2307. This means that anything wider than 72” needs additional evaluation, especially as there are manufacturing limitations regarding insulation width. Vertical seams can be challenging to employ, as there is no framing member for mechanical attachment and an unsupported vertical seam could allow curtain wall insulation to become dislodged and the seam to open due to extreme movement in a fire event. As vertical seams in insulation would continue through the interior joint behind the safing insulation, this could also provide a way for fire to breach the safing line.

PFC system design consideration:

UL®-reviewed and -approved options are available from Owens Corning® Thermafiber® to address wider spandrels. However, most situations with wider spandrels need to be examined on a case-by-case basis by the Thermafiber Insolutions® team to provide recommendations on these design installation situations.

Special Condition #3: Steel back pan use

Steel back pans are increasingly popular with the expansion in unitized systems – steel back pans can be used as a vapor barrier and are perceived to be more robust PFC systems. However, these systems can present challenges if they are not properly evaluated and constructed – steel does not melt, but it can “oil can” or buckle, creating peaks and valleys and allowing fire and gases to move upward through openings created by these peaks and valleys.

PFC system design consideration:

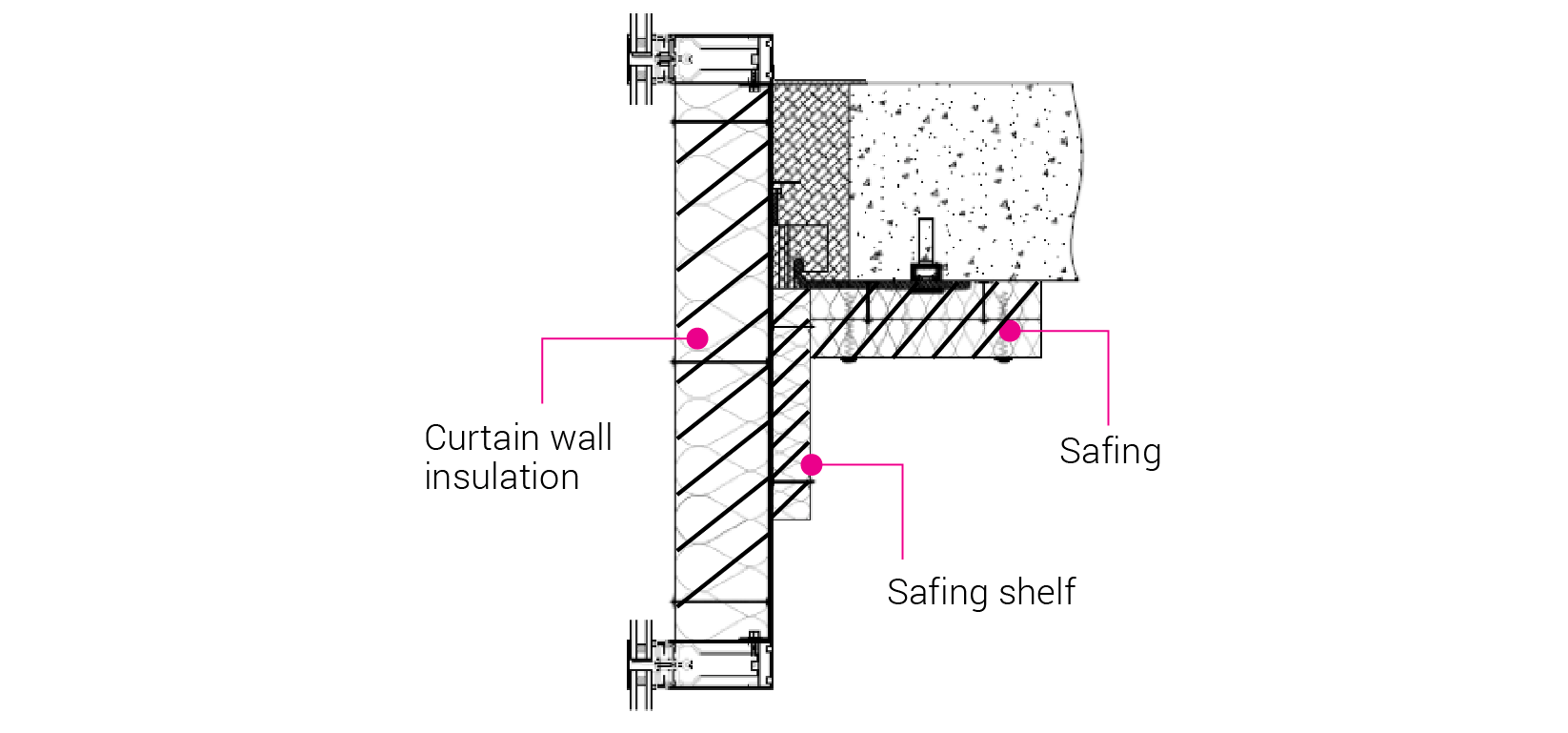

Specific UL® or Intertek® systems have been established to provide adequate protection to these systems. Some considerations include adding reinforcement behind the back pan to help prevent it from warping or to add a safing shelf to reduce the chance of seams forming between the steel back pan and insulation. Steel back pans also require a higher frequency of attachment to the curtain wall spandrel framing than other PFC assemblies. The curtain wall insulation within the backpan panels also requires an increased frequency of mechanical attachment to keep the insulation securely in position during a fire event. More details on how to best protect and use these systems can be found in the UL® or Intertek® Fire Resistance Directory or by contacting Insolutions® Services.

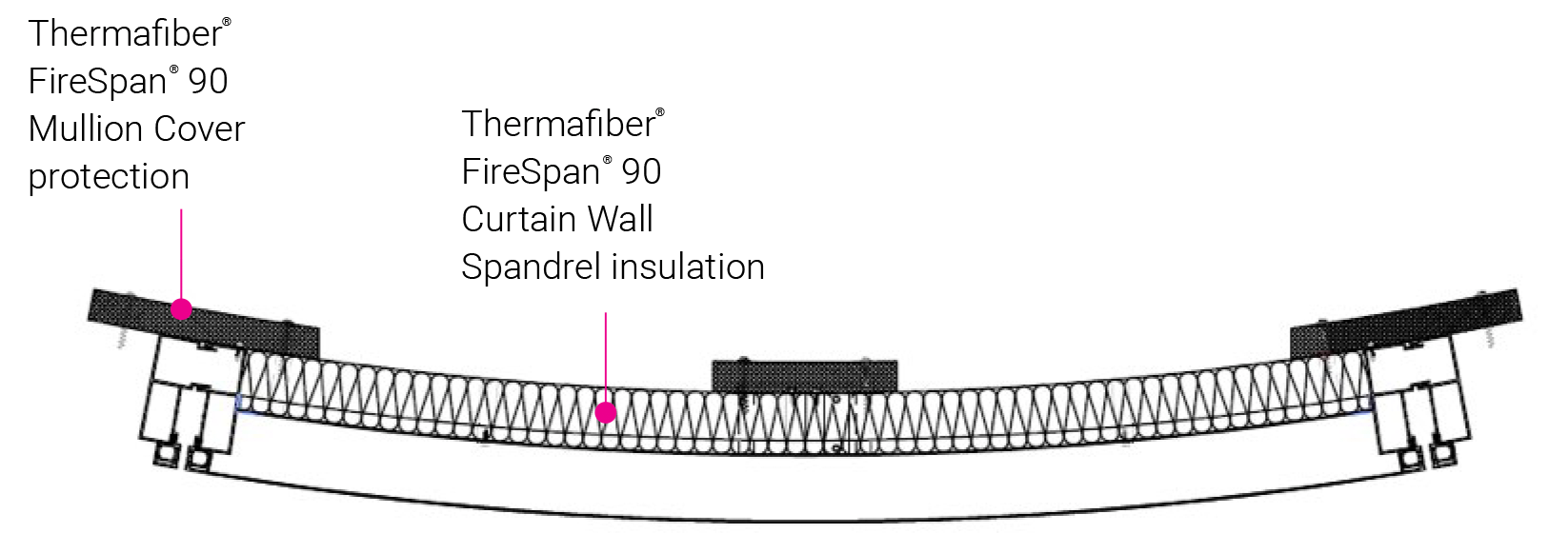

Special condition #4: Curved spandrel walls

No tested or listed assembly for curved curtain walls has been established, and the ability of spandrel insulation to conform to the curve can depend on the degree and uniformity of the arc.

PFC system design consideration:

There are few mechanical attachment options for this type of assembly, meaning custom fasteners will likely be required. Additionally, in conditions where the slab edge does not follow the same radius as the curtain wall, a radius backer reinforcement is necessary behind the spandrel insulation and must be designed to work with the project detail. Adjustments also will be needed where joint widths vary between the slab and insulation. Conditions posed by curved spandrel walls should be examined by the Thermafiber® Insolutions® team and recommendations are provided on a case-by-case basis.

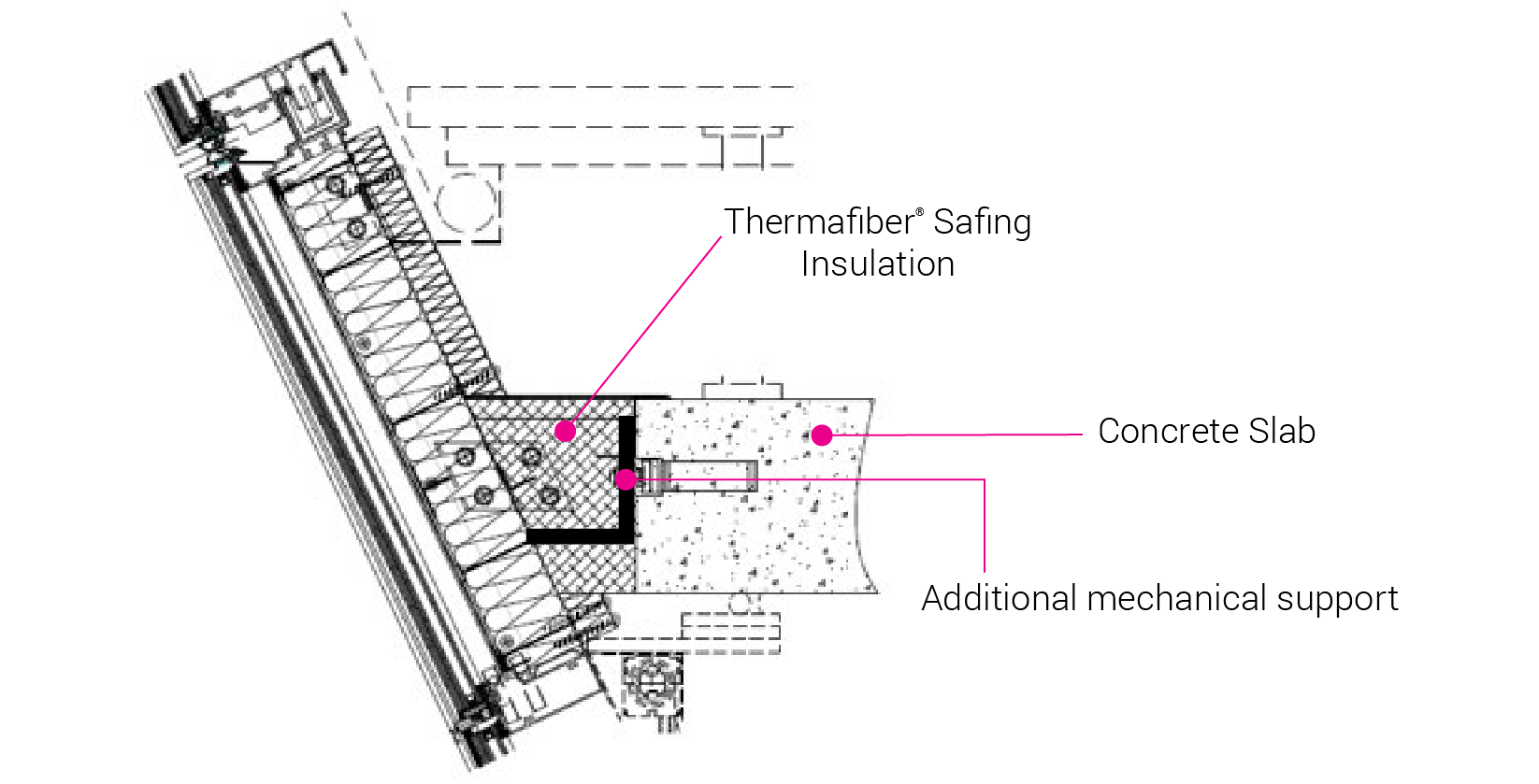

Special condition #5: Angled spandrel walls

There are no tested or listed assemblies for angular curtain walls. It can be challenging to secure the safing insulation in the linear joint. Also, the orientation of the angled curtain wall to the floor slab needs to be taken into consideration when designing the PFC system. For example, an outward angle increases the spandrel’s exposure should a fire occur. The variable linear joint widths also make it hard to achieve safing compression.

PFC system design consideration:

Mechanical attachments may be needed to keep insulation from moving throughout the lifetime of the building or in a fire event. However, limited mechanical attachment options mean that custom mechanical fasteners may be required along with custom supports in these situations.

Conditions arising from the use of angled spandrels are assessed on a case-by-case basis and the Thermafiber Insolutions® team is able to provide individualized recommendations.

Special condition #6: Exposed curtain wall anchors at the floor line

Curtain wall anchors mounted at the edge of the slab or below the concrete floor still need to be protected from direct fire exposure, since unprotected anchors exposed to fire and high temperature increase the possibility of complete system failure.

PFC system design consideration:

Exposed curtain wall anchors should be protected. In most cases, mechanically attached Firespan® 90, 40 or Safing Insulation at least 4” thick is needed to fully encapsulate and help protect exposed anchors. However, these exposed anchors must be evaluated on a case-by-case basis for proper thickness and attachment of mineral wool insulation. UL® also has established a new category – XHDI – specifically for perimeter fire containment accessories including anchor protections.

In addition to being a member of the International Firestop Council, a nonprofit that works with passive fire protection materials and systems, the Owens Corning Thermafiber Insolutions® team exists to provide technical expertise on passive fire protection. Insolutions can offer consultation and feedback in multiple areas including the development of expert engineering judgments, CAD drawings and guidance on good design practices and recommendations for specific product use.

Related Articles

Related Articles

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite