Defend.

Defend.Helps Protect Against Nature's Elements

Helps Protect Against Nature's Elements

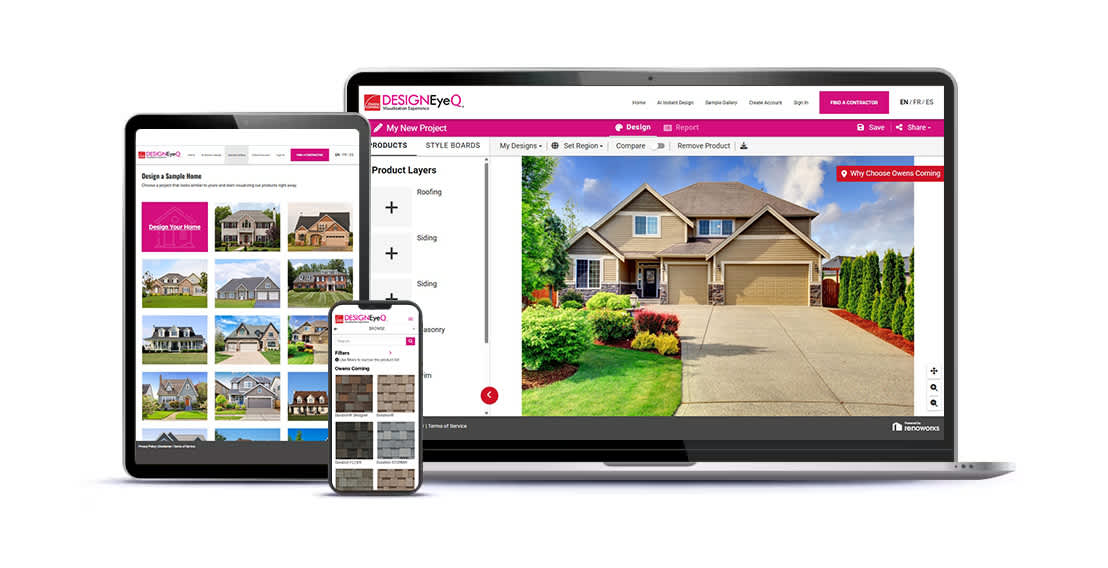

Owens Corning® LongRidge® Extended Hip and Ridge Shingles offers a unique broad look with an extended exposure to top off the residential roofing system. LongRidge™ Extended Hip and Ridge Shingles protects ridge vents and roof peaks from the elements while adding a bold dramatic appearance with vibrant colors.

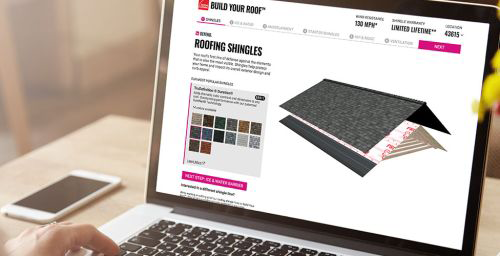

- Wind-resistance up to 130 MPH*

- Extended 10” exposure allows for quick installation

- Coordinates with the Owens Corning® laminate shingle colors for a perfect match and consistent look

- Limited Lifetime* Warranty when installed with the Owens Corning® Laminate Shingles

- Algae Resistant

Part of the Owens Corning® Total Protection Roofing System®^.