- Fire

- Commercial

- Blog

Six Critical Components of a Listed Perimeter Fire Containment Assembly

Blog in Brief

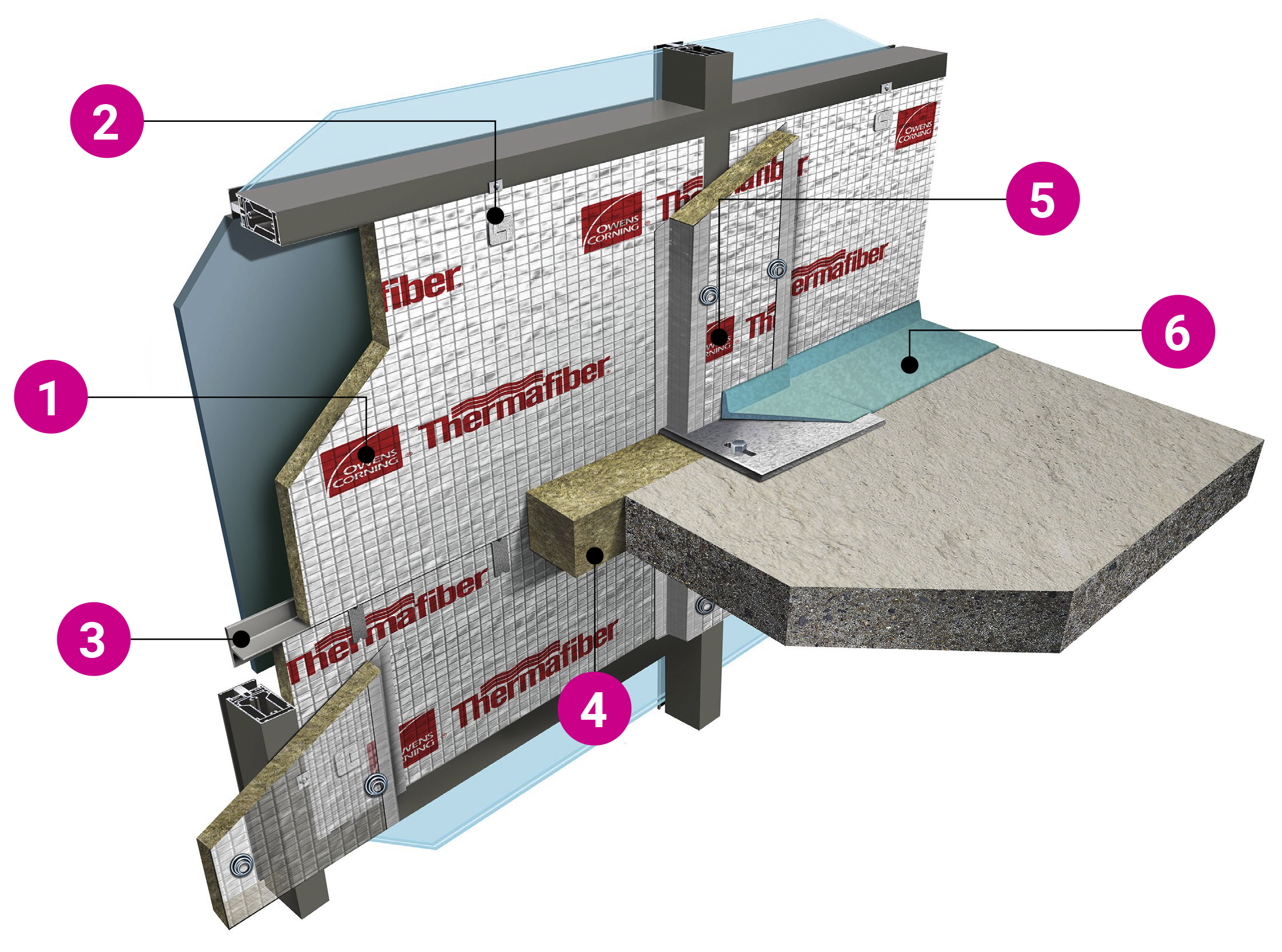

There are six critical components needed for a perimeter fire containment assembly to meet minimum code requirements and functions correctly. These include using the correct mineral wool product, mechanical attachments, reinforcement, compressed insulation, mullion covers and a smoke barrier.

Six Critical Components of a Listed Perimeter Fire Containment Assembly

Annually in the U.S., fire causes about 3,000 deaths and over $12 billion in property losses.1 In non-residential buildings alone, losses in 2019 were nearly $3 billion.2 These damages have been increasing in recent years, even as safety features and containment strategies – like perimeter fire containment systems – improve.3

A perimeter fire containment assembly is used to help prevent flame and hot gases from moving upward during a fire. The system seals the void between the floor slab and the interior side of the exterior wall. Although design considerations are needed to customize perimeter fire containment assemblies, several critical components are universal.

Common design elements consistent across perimeter fire containment assemblies include:

- Mineral wool insulation – Mineral wool insulation tested and compliant to ASTM E2307 is the only insulating material that has been documented as being capable of protecting spandrel wall components and providing a barrier to flame and hot gases at the perimeter void. In fact, just to demonstrate the fire performance characteristics of mineral wool, Thermafiber® FireSpan® was tested to ASTM E119 and found that it was able to stay fully intact after 5 hours of fire exposure to temperatures higher than 2,000°F (1,093.3 °C). When installing Thermafiber® FireSpan® 40 or 90 mineral wool insulation to help protect the exterior curtain wall components, it should be mechanically attached within the spandrel opening.

It should be noted that the Thermafiber® FireSpan® 40 or 90 mineral wool insulation used in perimeter fire containment systems with fire ratings of up to 3 hours must be tested in UL® or Intertek® designs according to ASTM E2307.

See specific UL® or Intertek® listing for specific FireSpan® product to be used. - Mechanical attachments – Fires can generate turbulence, movement and gravitational pull, especially on insulation. Mechanical fasteners can keep insulation securely in place as the curtain wall is deteriorating during fire exposure. If insulation moves or becomes dislodged, it can provide fire a path to another floor.

Underwriters Laboratories (UL®) designs provide details on the specific Thermafiber® Impasse® fasteners that should be used to secure insulation. - Backer bar or reinforcement member – The backer bar or reinforcement member keeps the curtain wall insulation from warping after compression-fit safing insulation is installed. The reinforcement member can be a lightweight steel angle, T-bar or hat channel and is required to be at least 20 ga. galvanized steel – unless the design specifies a certain gauge. It is located behind the curtain wall insulation in line with the floor slab. If this reinforcement member is omitted in assemblies where the horizontal transom is greater than 3” below the floor slab, the curtain wall insulation will deflect, allowing loss of compression at the safing joint. Loss of safing compression can cause the safing to dislodge or allow flame through at the safing joint.

More information on the proper reinforcement member can be found within the specific system listing from UL® or Intertek®. - Safing insulation – Code requires that the safe-off area be sealed to help prevent passage of flame and hot gases through the joint. Thermafiber® Safing insulation should be installed at the correct compression, orientation and depth to seal this area.

Listed UL® or Intertek® systems provide guidance on how much compression is needed and in what orientation Thermafiber® Safing should be installed.

Thermafiber® Safing mineral wool insulation must be tested and approved in UL® or Intertek® Perimeter Fire Containment designs per ASTM E2307. - Protection of curtain wall vertical mullion framing – Exposed and unprotected aluminum components can melt at 1,220°F (660°C). This temperature may be reached 9 minutes after a fire starts. If the aluminum framework melts, the attachment points for securing the curtain wall insulation will fail, causing an early failure of the perimeter fire containment system. However, protecting aluminum mullions with Thermafiber® FireSpan® 90 mullion cover insulation can help prevent this from occurring and the perimeter fire containment remains in place.

Thermafiber® Mullion Cover Insulation can be attached with either Thermafiber® Spiral Anchors every 12” o.c. or with patented Thermafiber® Mullion Cover Brackets. - Smoke barriers – During a fire, smoke can be quite dangerous. It is responsible for a majority of fire-related deaths.4 However, applying an approved smoke barrier on top of the safing mineral wool insulation helps to impede smoke passage. See specific UL® or Intertek® design standards for approved smoke sealants.

References

- U.S. Fire Administration. “About the U.S. Fire Administration.” https://www.usfa.fema.gov/downloads/pdf/statistics/fire-estimate-summary-series.pdf#:~:text=Overall%20trends%20for%20residential%20building%20fires%20and%20losses,injuries.%20%C4%B5%20A%206%25%20increase%20in%20dollar%20loss.

- U.S. Fire Administration. (April 2021). “USFA Nonresidential Build Fire Trends (2010 – 2019).” www.usfa.fema.gov/data/statistics/nonresidential-fire-estimates/nonresidential-building-fire-trends.html

- U.S. Fire Administration. “USFA Trends in fires, deaths, injuries and dollar loss (2010 - 2019).” https://www.usfa.fema.gov/downloads/pdf/statistics/fire-estimate-summary-series.pdf#:~:text=Overall%20trends%20for%20residential%20building%20fires%20and%20losses,injuries.%20%C4%B5%20A%206%25%20increase%20in%20dollar%20loss.

- National Fire Protection Association. “Reporter's Guide: The consequences of fire.” https://www.nfpa.org/News-and-Research/Publications-and-media/Press-Room/Reporters-Guide-to-Fire-and-NFPA/Consequences-of-fire

Related Articles

Related Articles

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite