- Fire

- Commercial

- Blog

Dismantling 5 Common Perimeter Fire Containment Misconceptions

Blog in Brief

Perimeter fire containment (PFC) systems help limit fire from spreading in high-rise buildings, providing time for occupants to exit and fire personnel to extinguish the fire. However, systems must be well designed to function correctly. There are five common misconceptions to avoid during development of a perimeter fire containment system, including:

- All mineral wool is the same and can be used in a PFC system

- ASTM E119 is equivalent to ASTM E2307

- Steel back pans provide the most robust PFC systems

- Vertical mullion protection is optional

- Fire performance of exterior façade panels is not critical for PFC function

Dismantling 5 Common Perimeter Fire Containment Misconceptions

Perimeter fire containment systems can help architects support a higher level of safety in commercial buildings. However, there are five common misconceptions that need to be addressed when it comes to correctly designing and installing perimeter fire containment systems.

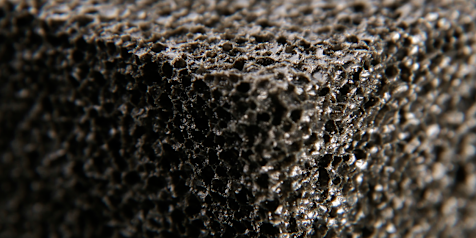

Misconception #1: Mineral wool is mineral wool

This is simply not true. In perimeter fire containment applications, mineral wool must provide a barrier, contain fire to the floor of origin and perform under direct flame impingement and accelerated temperatures as high as 1,800°F for periods up to 2-3 hours. The material used must demonstrate its ability to perform at the highest level. That is why it is important to specify PFC systems utilizing mineral wool which has been tested, verified and marked by the independent third-party laboratories specific to ASTM E2307. In addition, mineral wool manufacturers have patented equipment technologies and proprietary formulations that produce specific performance attributes.

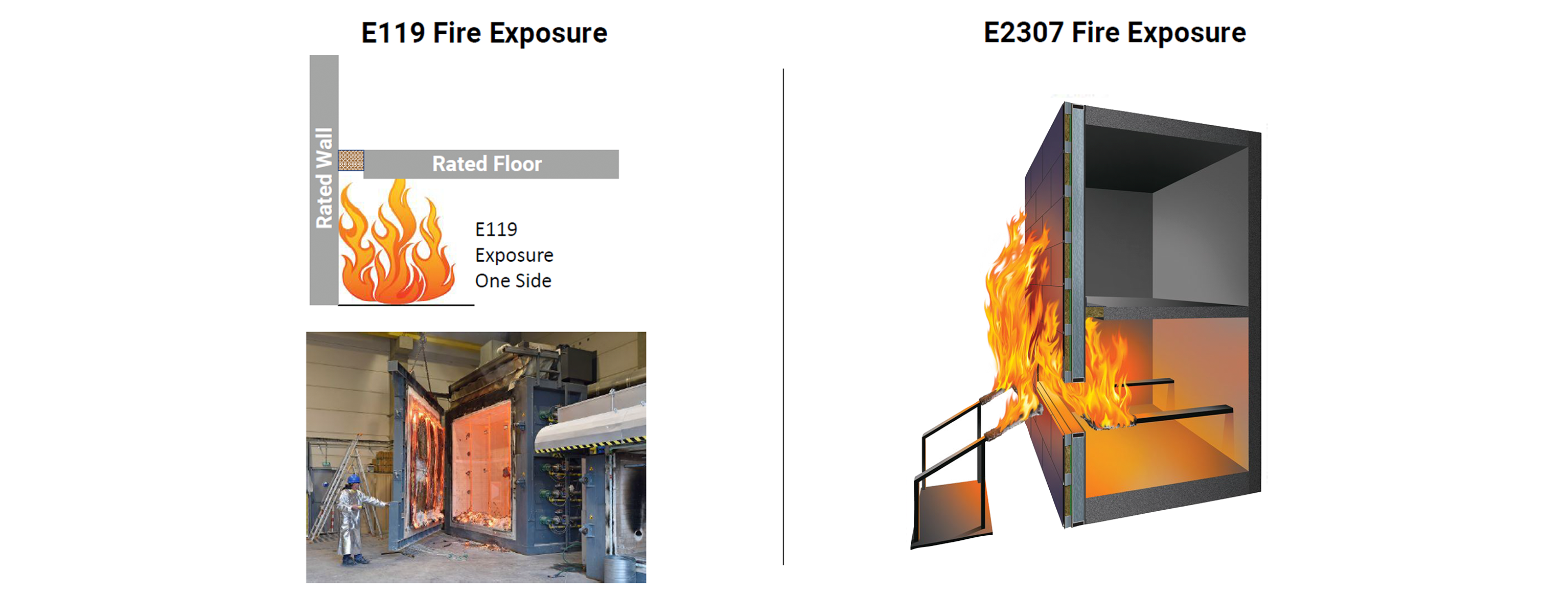

Misconception #2: ASTM E119 exception can be used in lieu of E2307 tested system

ASTM E2307 and ASTM E119 are not equivalent and do not use the same test method. ASTM E2307 exposes the assembly to fire on both sides at the same time for the 2- or 3-hour period of the fire test. In contrast, ASTM E119 exposes only one side of the system to fire and is not representative of an expected fire scenario in a high-rise building. The exception specifies that, when a curtain wall design has vision glass extending to the finished floor, the void at the intersection of the exterior curtain wall and floor assembly can be sealed with a material approved to prevent internal fire spread. The material used must be securely installed and able to prevent the spread of flame and hot gas based on ASTM E119 time-temperature conditions for the period equal to the fire resistance rating of the floor assembly.

However, when the exception was added, there were no systems that addressed this design and had been tested to ASTM E2307 – these systems now exist. It has since been found that filling the void but failing to protect the spandrel area can mean damage to the glass or aluminum may occur. It should be noted that aluminum melts out as early as 9 minutes into a fire. Following the E119 exception and installing mineral wool safing only between the floor and an aluminum horizontal framing member affords about 9 minutes of fire protection at the joint. If mineral wool safing is installed between the floor and spandrel or vision glass, this will provide about 5 minutes of protection before the glass breaks. These scenarios don’t allow occupants the time they need to evacuate a burning building.

Today, there are tested and listed systems designed for very short or zero spandrel curtain walls. These systems have been tested to E2307 for a 2-hour fire rating versus the 5-9 minutes of protection afforded by the E119 exception. Additionally, section 715.4 of the IBC requires E2307-compliant systems, while the exception only requires a material solution and does not provide building occupants equivalent protection.

Misconception #3: Steel back pans provide the safest, most robust PFC systems

The use of steel back pans in PFC systems is becoming quite common because of the popularity of unitized systems. However, these systems must be properly protected. When exposed to elevated temperatures, the steel pan will buckle and warp due to its high expansion coefficient. When this occurs, the safing insulation cannot maintain its compression or follow the warping or deflection of the back pan. Small seams may form at the safing line, allowing fire access to the next floor. Often, these back pans are constructed by others in a different location or even outside of North America. As U.S. and Canadian codes are different than other countries, it is important to know and understand what is being supplied. There are specific UL®- and Intertek®-listed systems that address the protection of these types of assemblies. However, it should be noted that these configurations are the most difficult to pass when testing to ASTM E2307.

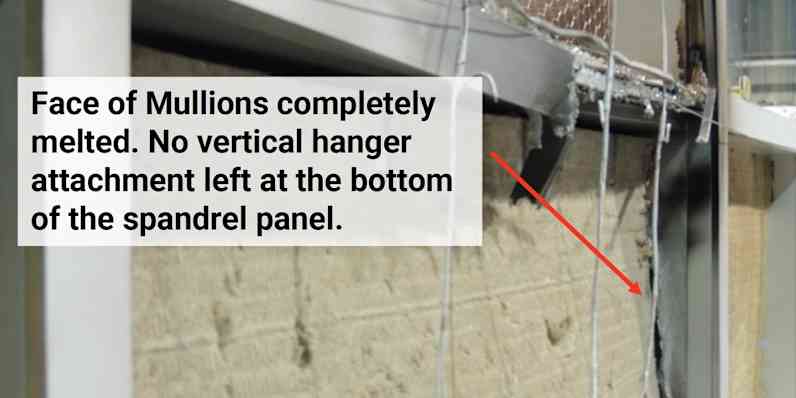

Misconception #4: Vertical mullion protection is not necessary

Face of Mullions completely melted. No vertical hanger attachment left at the bottom of the spandrel panel.

In 98% of all UL®- or Intertek®-tested and listed aluminum-framed curtain wall systems, vertical mullions within the spandrel area must be protected with UL®- or Intertek®-approved mineral wool mullion cover insulation. Aluminum will melt as early as 9 minutes into a fire. And yet, these aluminum framing members are critical for keeping the system together for the required hourly rating of the system. There are a few systems available where mullion covers are not required. These systems include unique design features that ensure all materials stay intact during a fire. It cannot be assumed that mullion covers are not necessary just because a few systems exist that do not require mullion covers. In fact, mullion covers should be utilized in 98% of all curtain wall assemblies as an added safety layer.

Misconception #5: Fire performance of exterior façade panels is not critical for PFC

We are starting to see exterior façade panels other than glass on high-rise structures. Increasingly, curtain wall designs include untested exterior façade panels, such as metal composite panels (MCMs), aluminum composite panels (ACMs) and high-pressure laminates (HPLs), among others. These combustible panels can add to the fuel load of a curtain wall under fire conditions.

When the fire performance per ASTM E2307 is unknown, exterior façade panels should be evaluated using NFPA 285. The purpose of this test is to determine that combustibles, when exposed to fire on the exterior face of the wall, do not allow for fire to spread a specified distance over the surface or through the core of the otherwise noncombustible wall assembly.

Additionally, the exterior panels should be attached independently from the PFC system. Combustible and untested panels should never provide structural support for the perimeter fire containment system. Also, other untested building materials with known fuel sources should never be part of a PFC assembly.

Related Articles

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite