System

Technical Consulting TeamThermafiber Insolutions®

Need a modification? Want a project-specific drawing? Reach out to our Thermafiber Insolutions®

team to request an Engineering Judgment.

Aluminum framed curtain wall with glass/aluminum/stone/granite spandrel. Min. 69" Spandrel. Thermafiber® Impasse® System with Thermafiber® 2" Firespan® 90 and Safing insulation. Hilti Sealant.

Assembly Details

F Rating | 2 Hr. |

T Rating | 1/4 Hr. |

Integrity Rating | 2 Hr. |

Insulation Rating | 1/4 Hr. |

Linear Opening Width | 4 in Max. |

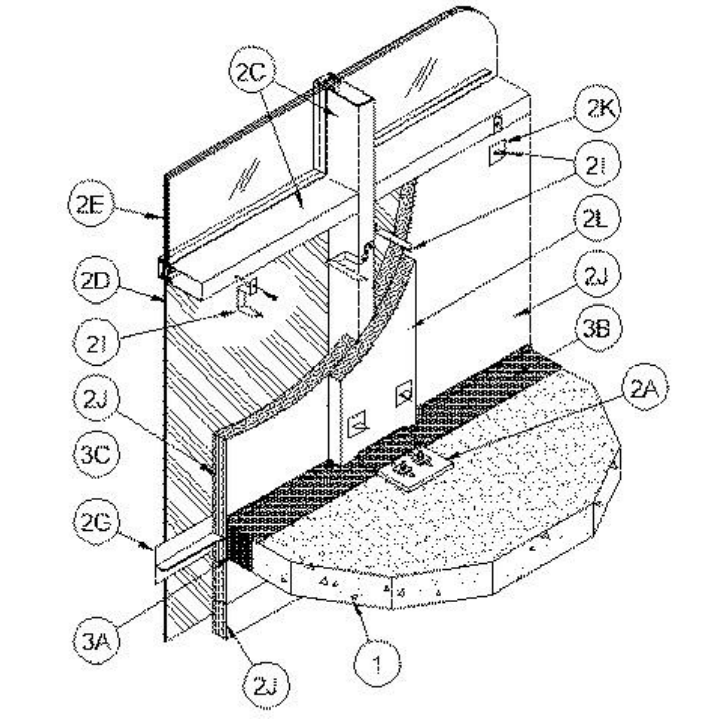

1. Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3 ) structural concrete.

2. The curtain wall assembly shall incorporate the following construction features:

A. Mullion Anchor Plates — Nom 7 in. (178 mm) wide by 9-1/4 in. (235 mm) long by 5/8 in. (16 mm) thick extruded aluminum plates with a nominal 1-3/4 in. (44 mm) high raised lip along one end to engage hooked ends of mullion mounting clips (Item 2B). Plates anchored to top surface of floor at each mullion location with steel wedge anchor bolts in conjunction with extruded aluminum washers.

B. Mullion Mounting Clips — Nominal 3 in. (76 mm) wide by 7 in. (178 mm) high extruded aluminum anchor slides with tapped holes and with separate extruded aluminum hooks designed to engage the raised lip of the anchor plate (Item 2A). Anchor slides bolted to each side of mullion at each floor with 1/2 in. (13 mm) diam stainless steel screws with locking washers. Anchor hooks secured to anchor slides with steel jacking screws and secured to raised lip of anchor plate with steel set screw.

C. Framing — The one-piece or split rectangular tubing mullions (vertical members) and transoms (horizontal members) shall be min 2-1/2 in. wide by 6 in. deep and shall be formed from min 0.125 in. (3.2 mm) thick aluminum. Mullions spaced max 60 in. (1524 mm) OC and secured to mullion anchor plates (Item 2A) with mounting clips (Item 2B) at each floor level. Interior face of mullions to be max 4 in. (102 mm) from edge of floor assembly. Transoms to be spaced min 69 in. (1753 mm) OC. The minimum height from the top of the floor to the bottom of the vision panel sill is 33 in. (838 mm).

D. Spandrel Panels — The spandrel panels shall consist of one of the following types: a. Glass Panels — Nom 1/4 in. (6 mm) thick opaque heat-strengthened glass. Each panel secured in position with aluminum pressure plates in conjunction with glazing gaskets and steel screws. b. Aluminum Panels — Nom 1/8 in. (3 mm) thick aluminum panels with 1/4 in. (6 mm) thick edges. Each panel secured in position with aluminum pressure plates in conjunction with gaskets and steel screws. c. Stone Panels — Nom 1-3/16 in. (46 mm) thick polished granite spandrel panels with 1 in. (25 mm) thick gauged edges. Each panel secured in position with aluminum pressure plates in conjunction with gaskets and steel screws.

E. Vision Panels — Nom 1 in. (25 mm) thick insulated glass units with two layers of nom 1/4 in. (6 mm) thick transparent heat-strengthened glass separated by a 1/2 in. (13 mm) air space. Each panel installed on silicone rubber setting blocks and secured in position with aluminum pressure plates in conjunction with glazing gaskets and steel screws.

F. Light Gauge Framing* — T-Bar Support Brackets — Nom 2 in. (51 mm) wide brackets formed from galv steel and designed to bridge extruded aluminum anchor slides of mullion mounting clips (Item 2B). Each T Bar support bracket provided with nominal 3 in. (76 mm) wide by 3 in. (76 mm) high leg with a nominal 3/4 in. (19 mm) hemmed edge to receive the bottom edge of the T-Bar (Item 2G). T Bar support bracket secured to each side of mullion using the same bolts used to attach the anchor slides of the mullion mounting clips. The hemmed edge of the T Bar support bracket is to be located 3-1/2 in. (89 mm) below the top surface of the floor slab such that, when installed, the stem of the T Bar (Item 2G) will be located 2 in. below the top plane of the floor slab. Angle of T Bar support bracket to be recessed from interior face of framing as necessary to accommodate the thickness of the curtain wall insulation (Item 2J). THERMAFIBER INC

G. Light Gauge Framing* — T-Bar — Nom 3 in. (76 mm) wide by 1-1/2 in. (38 mm) high tee section formed from galv steel. T Bar installed between mullions at each floor level to restrain curtain wall insulation (Item 2J) against outward movement when forming material (Item 3A) is installed. The T Bar shall be installed with a clearance of 1/2 to 3/4 in. (13 to 19 mm) at each end. The bottom edge of the T Bar shall rest in and be supported by the hemmed edge of the T Bar support bracket (Item 2F) at each end. The top edge of the T Bar shall be locked in place with a locking clip (Item 2H) at one end and by a min No. 10 by 1/2 in. (13 mm) long selfdrilling, self-tapping steel screw at the opposite end. Each T Bar shall be located with its stem at an elevation 2 in. (51 mm) below the top plane of the floor. THERMAFIBER INC

H. Light Gauge Framing* — T-Bar Locking Clip — Nom 1 by 1-1/4 in. (25 to 32 mm) clips formed from galv steel and designed to lock top of T Bar (Item 2G) to T Bar support brackets (Item 2F). THERMAFIBER INC

I. Light Gauge Framing* — Vertical and Horizontal Hangers — Vertical and horizontal hangers formed from 1 in. (25 mm) wide galv steel strips, supplied in two configurations with length as needed to accommodate thickness of curtain wall insulation (Item 2J) and mullion cover (Item 2L). Vertical hangers (with 90 deg twist) screw-attached to interior face of mullions with No. 10 by min 1/2 in. (13 mm) long self-drilling, self-tapping steel screws. Vertical hangers on mullions to be located near each corner of each piece of curtain wall insulation except for the nominal 7 to 9 in. (178 to 229 mm) high piece of curtain wall insulation located immediately beneath the stem of the T Bar. The 7 to 9 in. (178 to 229 mm) high piece of curtain wall insulation immediately beneath the stem of the T Bar requires only one vertical hanger near its\' midheight at each end. Horizontal hangers (without twist) screwattached to T Bar (Item 2G) and to transom at top of spandrel panel (sill of vision panel) with No. 10 by min 1/2 in. (13 mm) long self-drilling, self-tapping steel screws. Horizontal hangers on T Bar to be located within 6 in. (152 mm) of mullion at each end and spaced max 16 in. (406 mm) OC. Horizontal hanger on transom at top of spandrel panel to be located at center of transom. No hangers are to be used on the transom at the bottom of spandrel panel (lintel of vision panel). THERMAFIBER INC

J. Curtain Wall Insulation* — Min 2 in. (51 mm) thick mineral wool batt insulation faced on one side with aluminum foil/scrim vapor retarder, supplied in min 36 in. (914 mm) wide batts. Insulation batts to be installed with no vertical seams. A horizontal seam is to be located 7 to 9 in. (178 to 229 mm) below the stem of the T Bar in each spandrel area and is to be sealed with aluminum foil tape. In the spandrel area beneath the stem of the T Bar, insulation panels tightly-fitted between vertical mullions and between the stem of the T Bar (Item 2G) and the transom, flush with the interior surface of framing. Insulation panels impaled on vertical and horizontal hangers (Item 2I) and secured in place with nom 2 by 2 in. (51 by 51 mm) steel locking washers (Item 2K). THERMAFIBER INC — Firespan 90

K. Light Gauge Framing* — Locking Washers — Nom 2 by 2 in. (51 by 51 mm) clips formed from galv steel and designed to secure curtain wall insulation and mullion covers on vertical and horizontal hangers (Item 2I). THERMAFIBER INC

L. Mullion Covers — Curtain Wall Insulation* — Nom 2 in. (51 mm) thick mineral wool batt insulation faced on one side with aluminum foil/scrim vapor retarder, supplied in min 24 by 48 in. (610 by 1219 mm) boards. Nom 12 in. (305 mm) wide strips to be centered over mullions and impaled on the same vertical hangers used to secure the spandrel panel insulation and secured in place with nom 2 by 2 in. (51 by 51 mm) locking washers (Item 2K). Mullion covers to abut the forming material (Item 3A) above and below the floor. THERMAFIBER INC — Firespan 90

M. Light Gauge Framing* — Spiral Anchor — (Not Shown) — As an alternate to the vertical hangers (Item 2I), galv steel wire spiral anchors may be used to secure the framing covers (Item 2L) to the curtain wall insulation (Item 2J) on each side of the mullion. Nom length of spiral anchors to be equal to thickness of curtain wall insulation plus thickness of framing cover. Spiral anchors driven through mullion covers and into curtain wall insulation and spaced max 12 in. (305 mm) OC. THERMAFIBER INC

3. Max separation between the edge of the floor and the face of the framing members (at time of installation) is 4 in. (102 mm). The safing system is designed to accommodate vertical shear movement up to a max of 5 percent of its installed width. The safing system shall incorporate the following construction features:

A. Forming Material* — Nom 4 pcf (64 kg/m3 ) density mineral wool batt insulation. Batt sections cut to a min 4-1/2 in. (114 mm) width and stacked to a thickness which is min 25 percent greater than the width of linear gap between the curtain wall insulation and the edge of the concrete floor slab to attain a min 20 percent compression in the thickness direction. The forming material is compressed and inserted cut-edge-first into the linear gap such that its top surface is flush with the top surface of the floor assembly. Forming material to extend completely beneath mullion mounting plate (Item 2A). A max of two tightly-butted seams are permitted in the forming material between mullions.

B. Fill, Void or Cavity Material* — Min 1/8 in. (3.2 mm) wet thickness (min 1/16 in. or 1.6 mm dry thickness) of fill material spray-applied over top of forming material and lapping min 1/2 in. (13 mm) onto the top surface of the floor and onto the curtain wall insulation, mullion anchor plate (Item 2A) and framing covers. When CFSSP SIL is used, min wet (and dry) thickness of spray is 2 mm. HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CFS-SP SIL Firestop Silicone Joint Spray or CFS-SP WB Firestop Joint Spray

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada), respectively.