- Sustainability

- Commercial

- Blog

Reviewing the ins and outs of the LEED program

Blog in Brief

The LEED framework was created to support and guide green building efforts. The most recent update of the system – LEED v4.1 – seeks to improve how projects are discussed among project members in the early stages and to support increased transparency regarding the materials selected and used. Additional attention is being turned to the role of integrated planning and the use of environmental product declaration (EPDs) to select materials that reduce a building’s total environmental impact.

Reviewing the Ins and Outs of the LEED Program

Although “green building” can be something of an ambiguous term, one interpretation is that buildings designed or refurbished in a “green” manner are intended to address construction practices, material manufacture and efficiency as a way to allow individuals the ability to thrive in a safe, healthy and sustainable way. As such, green building also continues to be an expanding and profitable section of the construction industry. From 2006 to 2018, the number of LEED-certified projects increased from about 300 to more than 67,200 – just in the U.S.1 Currently, nearly 100,000 projects are taking part in LEED, stretching across more than 180 countries and territories, according to the organization. The prediction is that the market could see a 14.3% CAGR though 2027.2

What is the LEED rating system?

Started in 1998, the U.S. Green building Council’s Leadership in Energy and Environmental Design (LEED) rating system was designed to provide leadership and transparency for the green building movement. The Council seeks to change the way that buildings and communities are designed, constructed and used so they will provide an environmentally and socially responsible experience that can boost quality of life. LEED is the system created to bring about this transformation by providing a framework that can be used to develop healthy and efficient buildings that also allow for long-term cost savings. Guidelines also address improving indoor air quality and, by virtue of being energy efficient, help reduce pollution and outdoor air quality.

The LEED framework can address multiple types of buildings and different building phases, including new construction, retrofits, operations and maintenance, core and shell work, neighborhood development, single family home design and city and community development. Projects working toward a LEED certification gain points for integrating green building strategies and materials into the process at stages specified across several categories. The points earned are used to determine which rating level has been achieved.

Highlighting changes for LEED v4.1

The newest version of the LEED framework – LEED v4.1 – was introduced in January of 2019 and the final polishing of the guidelines (or beta testing) is still being completed. Within the new version, the framework for building design and construction (BD+C) can address several types of projects, including new construction, major renovations, core and shell development, schools, retail, data centers, warehouses and distribution centers, hospitality and healthcare facilities.

One element of the process that sees additional emphasis in the most recent iteration is the use of an integrated design process. While this was mentioned in previous versions of the system, how it is handled and reported has changed. Now, there is a credit available for design teams that engage with all members early in the process. The goal of the shift is to find benefits and optimizations that can be carried all the way through the construction process.

The shift was established following a review of past LEED construction projects, because it was determined that in earlier efforts construction was not viewed holistically. Taking a more limited view could mean that while sections of a project were optimized, the way changes were made may have created issues for other stages or that full improvements were not realized.

The new system is intended to break down silos created in the design and building process. How the integrated design-stage work is reported also has changed. Using the new method, project teams are asked to write a letter telling the story of the project instead of filling out a worksheet. Each area and issue reviewed during the process should be explained and all members of the project team must sign off on the document.

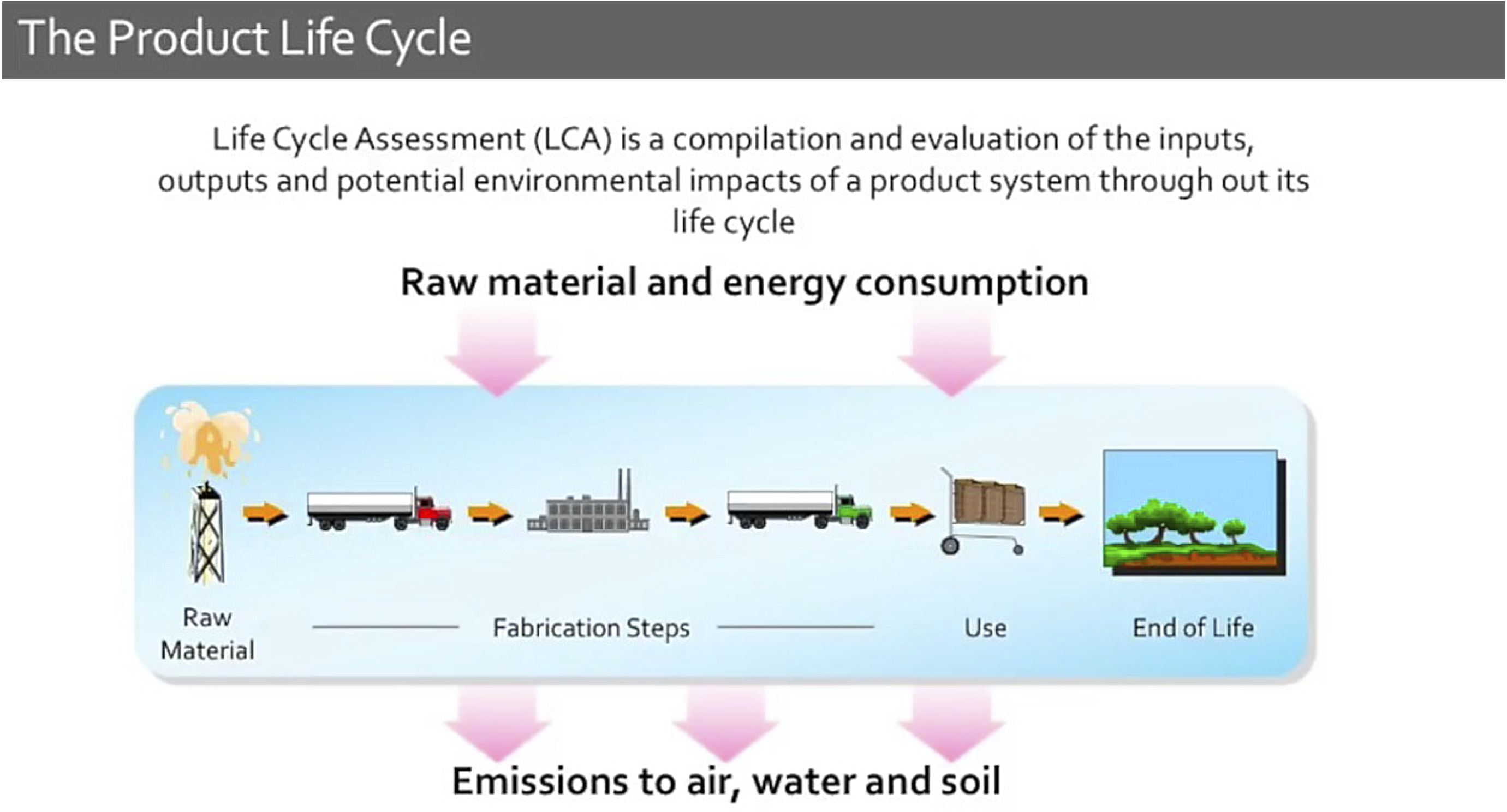

More emphasis also has been placed on supporting the selection of products with improved performance. This effort included changing how elements like a material’s embodied carbon or life cycle assessment (LCA) are reported. The LCA is a review that analyzes every element and phase of a product’s production.

The shift is intended to support manufacturers working to show their transparency journey and highlight the improvements being made. With the understanding that a completed building is comprised of multiple materials, it is important to consider materials used and have a standardized, scientific way to report on environmental performance and material health parameters. These aspects were once on the fringe of the LEED framework but are now considered essential performance attributes.

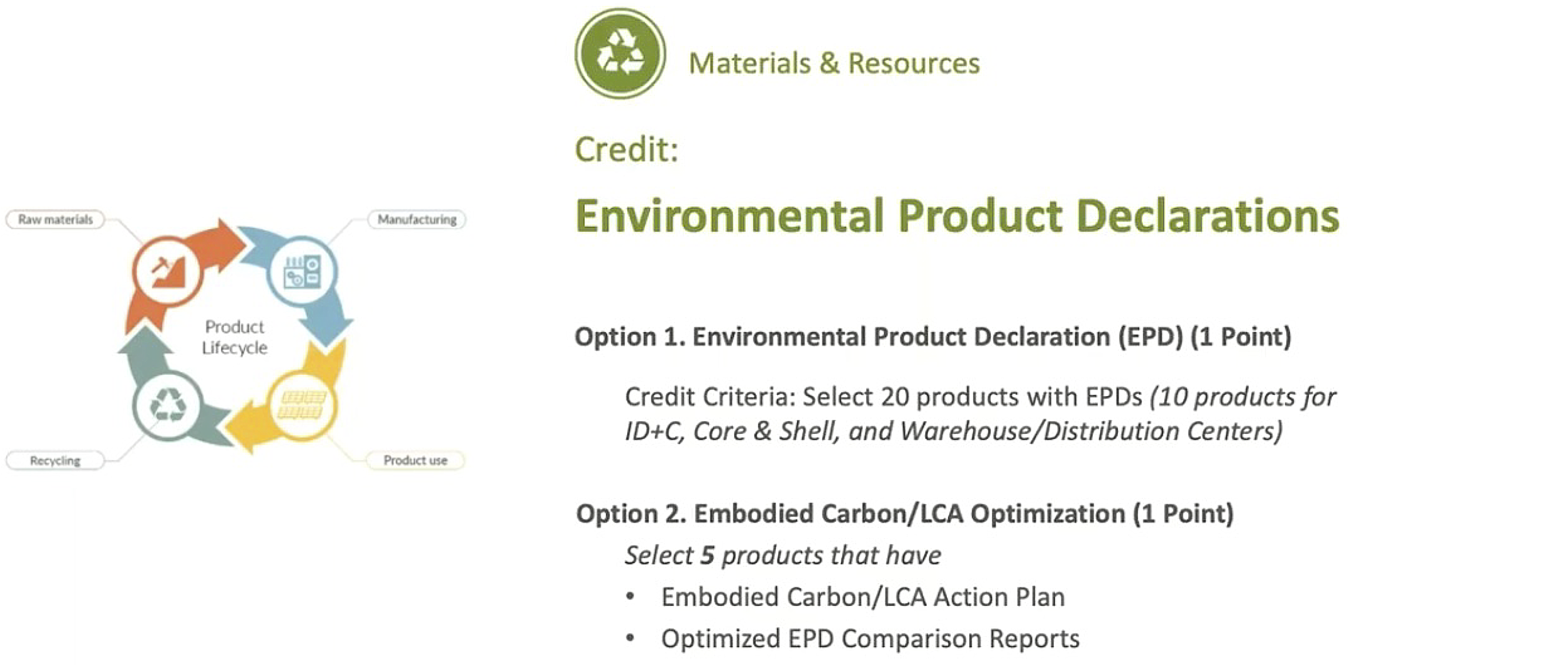

As such, the new version seeks to encourage the use of EPDs by making requirements clearer and easier to use. An EPD is a publicly available third-party verified document that provides details of a product’s complete environmental performance or the results of its LCA.

The updated reporting system focuses more on the outcome of changes made to improve products. Interest in claiming this credit using the revised process has already improved.

Additionally, while energy and water analyses are required, they are now the only required elements of that nature. Other assessments for key criteria are encouraged, but teams no longer have to hit a specific number. Instead, extra points are available for having analyses for project aspects like site selection, social equity or health and well-being. The shift is intended to allow project groups to focus on the analyses that are most important and relevant to their projects.

LEED and Owens Corning

The materials-focused sustainability work that Owens Corning has done in the past has focused on products in the insulation, roofing and composite reinforcement areas. Some of the products developed include FOAMULAR® NGX™ high-performance XPS insulation, Thermafiber® mineral wool products and roofing shingles, such as Duration® Premium Cool Shingles, which may help reduce a building’s energy demand. To provide more transparency on an individual-product basis, EPDs and optimization summaries have been written for several products and many products have been certified by third-party entities regarding elements like the use of recycled materials, wind-generated energy and chemicals used in production.

For example, FOAMULAR® NGX™ extruded polystyrene insulation, when compared to the legacy version of FOAMULAR® XPS rigid foamboard insulation, provides a picture of the progress that has been made in product design. The revamped insulation uses a blended blowing agent that reduces the product’s Global Warming Potential (GWP) by more than 80% compared to the legacy product. The reduction has been documented in an Optimization Summary, verified by UL, which qualifies the insulation as two products toward the Materials and Resources: Environmental Product Declarations: Option 2, Embodied Carbon/LCA Optimization point.

The interest from designers and builders in selecting and using products specifically because they have more transparency information available is supporting work in this area for the company. It provides a good story and a financial incentive to invest in the disclosure process.

Conclusion

LEED v4.1 is the most recent iteration of the standards framework intended to guide and expand green building design, construction operations and performance. In the BD+C segment, changes to the system highlight the role of the EPD and emphasize the outcome of product selection looking at elements like waste prevention and embodied carbon. The goal of these and other updates to the program is to make EPDs more usable and provide greater transparency for material selection and use.

References

Related Articles

Related Articles

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Jump to a Solution Suite

Jump to a Solution Suite