System

Technical Consulting TeamThermafiber Insolutions®

Need a modification? Want a project-specific drawing? Reach out to our Thermafiber Insolutions®

team to request an Engineering Judgment.

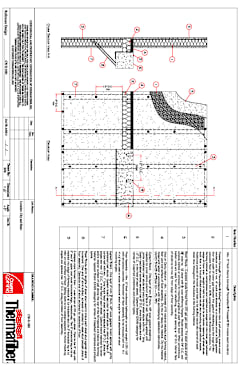

Steel framed with interior/exterior gypsum board, Brick, Stucco, Siding. 2- HR. F. Thermafiber® 3" Firespan® 90 and Safing insulation. USG Sealant.

Assembly Details

F Rating | 2 Hr. |

T Rating | 3/4 Hr. |

Integrity Rating | 2 Hr. |

Insulation Rating | 3/4 Hr. |

Linear Opening Width | 8 in Max. |

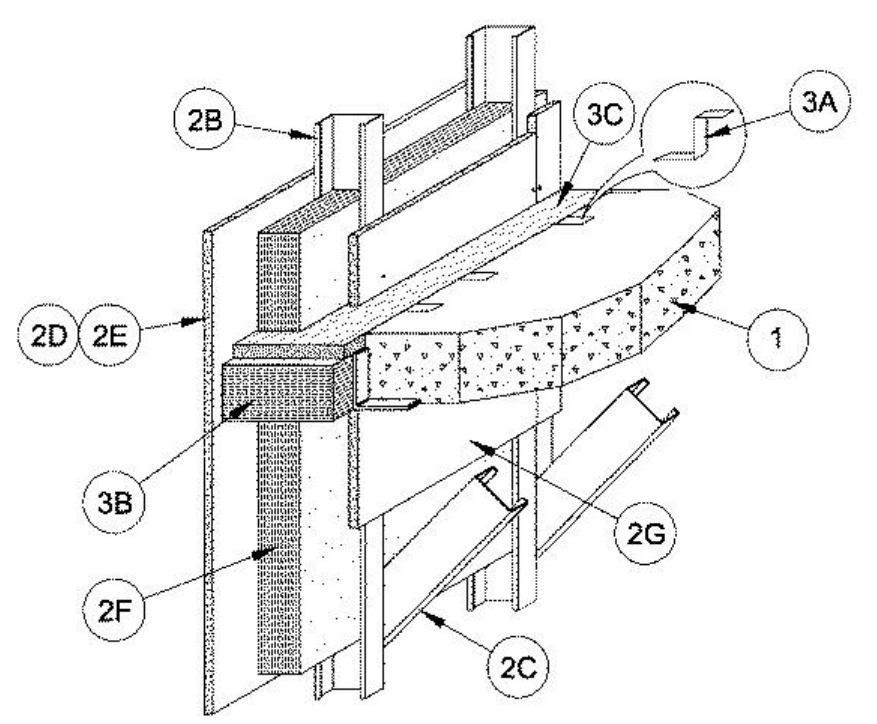

1. Min 5 in. thick reinforced lightweight or normal weight (100-150 pcf) structural concrete. Perimeter of floor assembly to be provided with min 4 by 4 by 1/4 in. thick cast-in-place structural steel angle for weld-attachment of stud mounting angles (Item 2A).

2. The curtain wall assembly shall incorporate the following construction features:

A. Mounting Angles — (Not Shown) — Min 4 in. long angles with one nom 4 in. leg for attachment to edge of floor assembly and with one leg approx 2-1/2 to 3 in. longer than distance to interior face of steel studs. Angles to be formed of min 1/8 in. thick steel. Angles welded to cast-in-place structural steel angle at edge of floor assembly (Item 1) on one side of each steel stud (Item 2B) at each floor level. Top edge of each mounting angle to be recessed 1 to 2 in. below top surface of floor.

B. Steel Studs — C-shaped studs formed from min 0.034 in. thick (20 ga) galv steel. The steel studs shall be 3-5/8 in. wide by 1-1/4 in. deep with 5/16 in. wide stiffening flanges. Studs spaced max 24 in. OC and welded, bolted or screwed to mounting angles (Item 2A) at each floor level. When cementitious backer units (Item 2E) are used for exterior sheathing, max stud spacing is 16 in. OC. Interior face of studs to be max 2-1/2 in. from edge of floor assembly.

C. Steel Struts — Short lengths of steel stud (Item 2B) used to brace each steel stud against lateral movement. One end of strut bolted, screwed or welded to steel stud beneath plane of floor assembly. Opposite end of strut anchored to underside of floor.

D. Gypsum Board* — One layer of nom 5/8 in. thick, 48 in. wide gypsum sheathing installed to cover entire exterior surface of wall. Sheathing applied with joints centered over studs and secured to steel studs with min 1 in. long bugle head steel screws spaced max 8 in. OC along the edges and max 12 in. OC in the field of each sheet. See Gypsum Board (CKNX) category for names of Classified Companies and product types.

E. Cementitious Backer Units* — As an alternate to the gypsum board sheathing (Item 2D), 1/2 in. or 5/8 in. thick square-edge boards attached to studs with 1-1/4 in. long corrosion resistant self-tapping wafer-head steel screws spaced 6 in OC. Joints covered with glass fiber mesh tape. UNITED STATES GYPSUM CO — Type DCB

F. Curtain Wall Insulation* — Min 3 in. thick mineral wool batt insulation, unfaced or faced on one side with aluminum foil/scrim vapor retarder, supplied in nom 24 in. wide batts. Insulation batts installed to completely fill all stud cavities of curtain wall above the top of the fill material (Item 3C) and below the forming material (Item 3B). Insulation batts to be friction-fitted between studs with adjoining lenghts of batt tightly butted. THERMAFIBER/OWENS CORNING — FIRESPAN 90

G. Gypsum Board* — One layer of nom 5/8 in. thick, 48 in. wide gypsum board applied with joints centered over studs. Gypsum board secured to steel studs on interior surface of curtain wall with min 1 in. long bugle head steel screws spaced max 8 in. OC along the edges and max 12 in. OC in the field of each sheet. Gypsum board installed to cover entire interior surface of wall above the top of the fill material (Item 3C) and below the forming material (Item 3B). See Gypsum Board (CKNX) category for names of Classified Companies and product types.

H. Siding, Brick or Stucco — Aluminum siding, steel siding, brick veneer or stucco attached to studs over gypsum sheathing or cementitious backer units and meeting the requirements of local code agencies. Brick veneer wall attached to studs with corrugated metal wall ties attached to each stud with steel screws.

3. The perimeter fire containment system shall incorporated the following construction features:

A. Support Clips — Z-shaped clips formed from 1 in. wide strips of 20 ga galv steel. Clips to be 3 in. high with 2 in. and 3 in. upper and lower horizontal legs, respectively. The 3 in. horizontal leg is to be impaled into edge of forming material (Item 3B) at its middepth and the 2 in. horizontal leg is to rest on top surface of floor. Support clips to be located 3 in. from each side of each stud (Item 2B) along perimeter of floor assembly.

B. Forming Material* — Nom 4 in. thick, nom 4 pcf density mineral wool batt insulation. Batt sections to be cut to a width 1/2 in. to 1 in. greater than the width of the gap between the gypsum sheathing and the edge of the concrete floor and compression-fitted into the perimeter joint such that its top surface is recessed 1 in. from top surface of floor assembly. Length of batt to be equal to on center spacing of steel studs such that it is friction-fitted between studs and mounting angles without seams. Additional pieces of mineral wool batt to be stuffed into cavity of each steel stud throughout the thickness of the forming material. THERMAFIBER/OWENS CORNING — SAF

C. Fill, Void or Cavity Material* — Min 1 in. thickness of fill material installed atop forming material, flush with top surface of floor assembly. Dry mix or ready-mix material. Dry mix material mixed with water in accordance with the accompanying installation instructions. UNITED STATES GYPSUM CO — FC, RFC

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada), respectively.