- Fire

- Commercial

- Blog

Balancing life safety, installation efficiency and design flexibility

Blog in Brief

Interest in using zero spandrel assemblies in perimeter fire containment (PFC) systems continues to increase as designers seek to maximize the use of vision glass while maintaining fire safety, interior view and outward building aesthetics. However, there remain challenges to using some existing zero or short spandrel assembly systems. While existing zero spandrel systems require expensive components – like back pans – a new patent-pending zero spandrel PFC system, the Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System using new Thermafiber® FireSpan® 120 mineral wool insulation and new patent-pending Thermafiber® Impasse® 2.0 Hangers, provides flexibility to meet current and evolving design challenges and helps streamline the installation process. The new Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System is tested and listed with Intertek® Laboratories as providing up to a 3-hour F rating of fire containment.1

Perimeter fire containment (PFC) in multi-story buildings remains integral to fire protection. It is an important element for allowing building occupants more time to escape, as they may be 20 or more stories above ground and have limited egress options, while responders also have few points of access. Since PFC systems are used to help slow or contain the spread of fire in a high-rise building, innovations in these systems are needed to enhance building design and support architectural creativity.

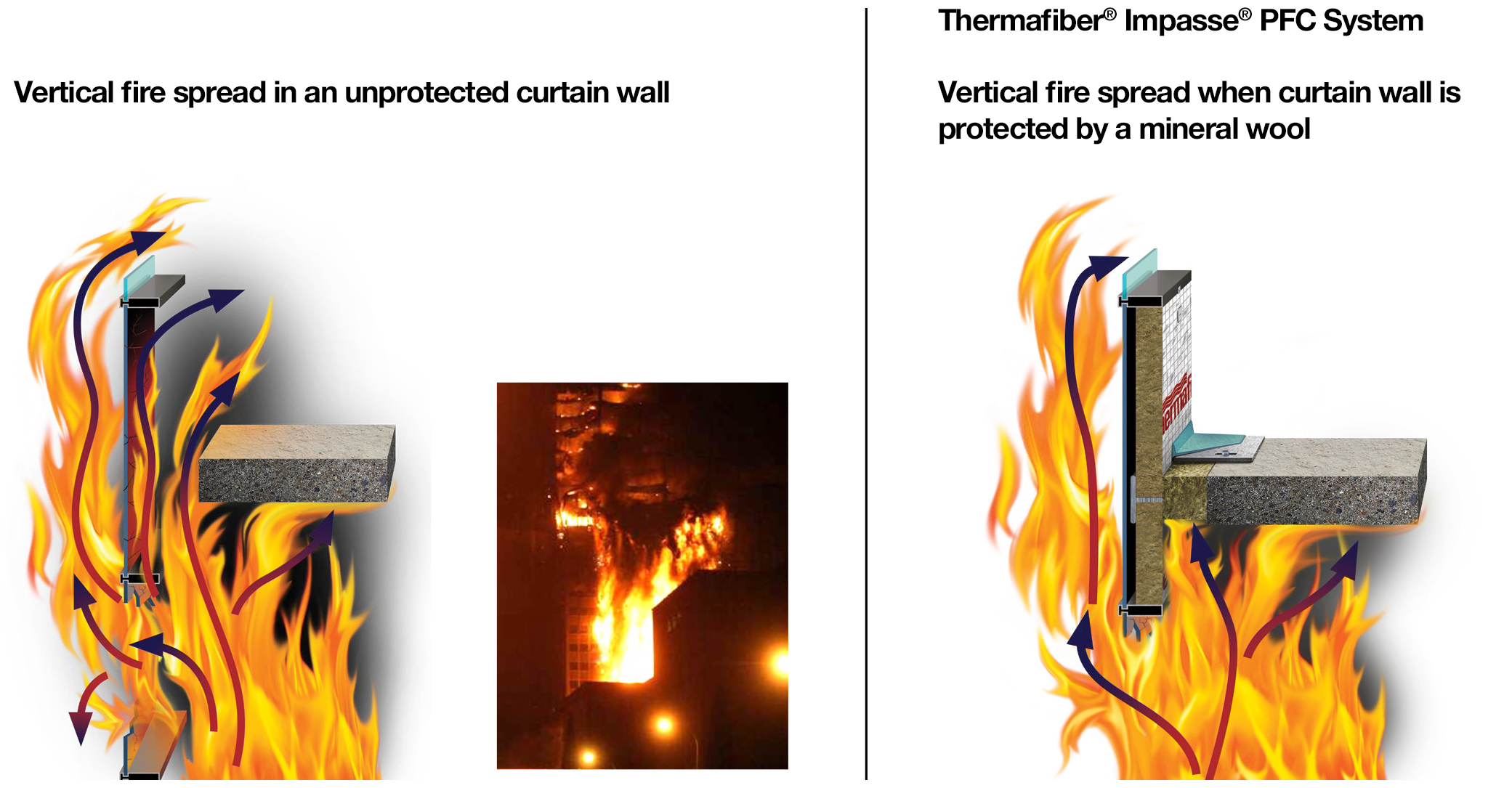

Perimeter fire containment systems seek to block the potential for fire to spread by moving up through the interior joint when a void exists between the floor assembly and exterior wall. A properly designed and installed PFC system blocks the path of fire through the interior joint.

The interest in designing high-rise buildings with attractive façades and maximized interior vision glass has created a challenge for architects and designers faced with the need to also incorporate PFC into structures. As the desire to increase the vision glass between floors in multi-story buildings grows, designers have had to shrink the spandrel, a portion of the façade that covers the floor slab or decking, which also limits the vertical space available to secure or achieve code-mandated PFC. This combination has prompted an uptick in the use of short or zero spandrel assemblies or use of the ASTM E119 exception, which does not provide a recommended level of PFC.

The spandrel is traditionally an opaque portion of the curtain wall used to conceal elements like structural beams. It also provides a space for thermal and firestopping insulation systems to be installed. Typically, spandrel panels include opacified spandrel glass, metal panels, thin stone and other elements attached to an aluminum frame. The height of spandrel panels can range from 6”-72” with widths of 24” to more than 100”, however, short spandrel systems are 19” or less in height. A zero spandrel system presents a challenge from an insulating and firestopping perspective, because it does not have the intermediate or lower horizonal transoms – aluminum framing – that a regular spandrel panel would include. This makes it more difficult to protect the exterior wall and maintain a fire barrier at the perimeter floor edge. However, the design flexibility these systems provide makes them popular.

Challenges to using zero spandrel assemblies

Traditionally, there have been several challenges to designing and installing zero or short spandrel PFC systems, including a lack of flexibility, restrictions to curtain wall attachments and a difficult and expensive installation process requiring components like back pans or large amounts of supporting steel, which increases material costs. Some systems also have installation limitations in the field.

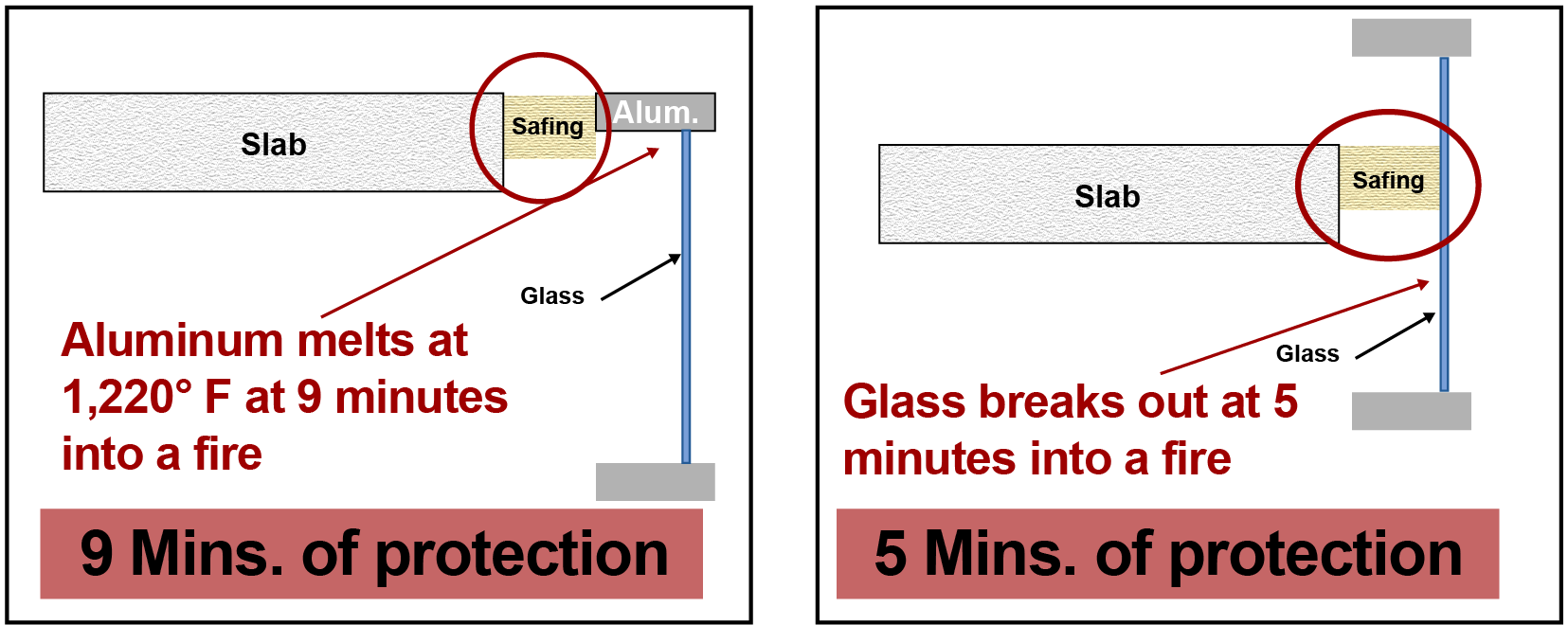

Should a fire occur, the exterior curtain wall experiences direct flame exposure and high temperatures, which can trigger failure points and allow fire to spread if an inadequate firestopping system is used. Temperatures in a fire can exceed 1,800 F, which would melt aluminum framing after about 9 minutes if only mineral wool safing is used to provide joint protection. The temperatures could also break the vision glass after about 5 minutes if mineral wool safing is only installed between the floor and the vision glass or spandrel.

Either of these scenarios could occur when a zero spandrel condition exists and designers choose to follow the International Building Code (IBC) exception under Section 715.4. The exception applies to the materials used to seal voids generated at the junction of an exterior curtain wall assembly and the type of floor wall assembly where vision glass extends to the finished floor level. The exception allows for voids to be filled with securely installed material capable of stopping the internal spread of fire based on ASTM E119 – Standard Test Methods for Fire Tests of Building Construction and Materials.2 To qualify for the exception, firestopping materials must remain in place and provide protection for a period equal to the fire resistance rating of the floor assembly. However, when a non-rated exterior wall is part of the assembly, the exception has not demonstrated an ability to properly evaluate and provide an hourly solution at the interior joint.

The exception was created during a period when there were no short or zero spandrel PFC systems that had been tested to ASTM E2307 – Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-scale, Multi-story Test Apparatus.3 It is still thought that the exception can be used instead of employing a system tested and listed to ASTM E2307, however, the two tests are not the same. The ASTM E119 test exposes materials to fire from only one side, while ASTM E2307 exposes an assembly to fire from both sides – more closely mimicking conditions during a high-rise fire event.

Improving zero spandrel PFC system design

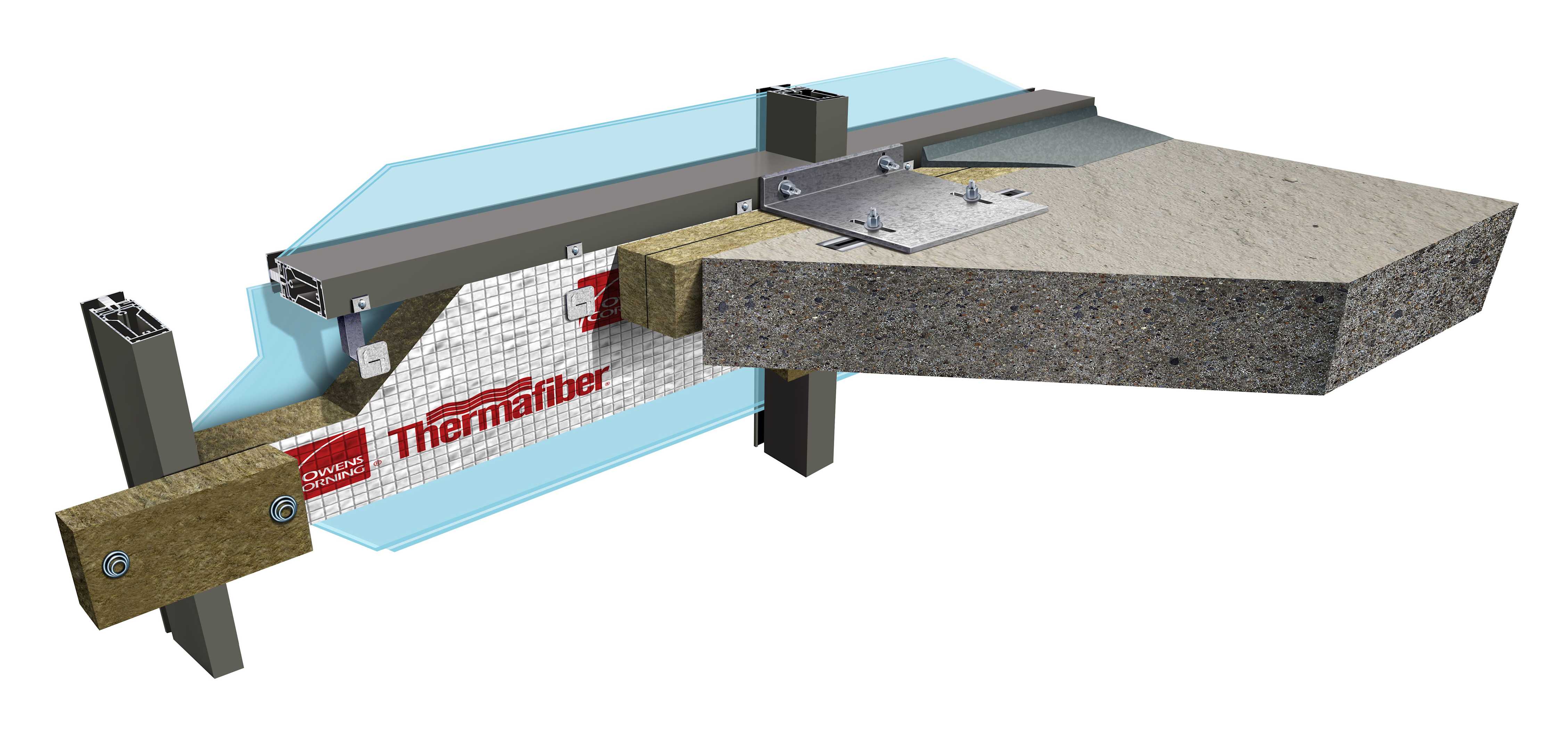

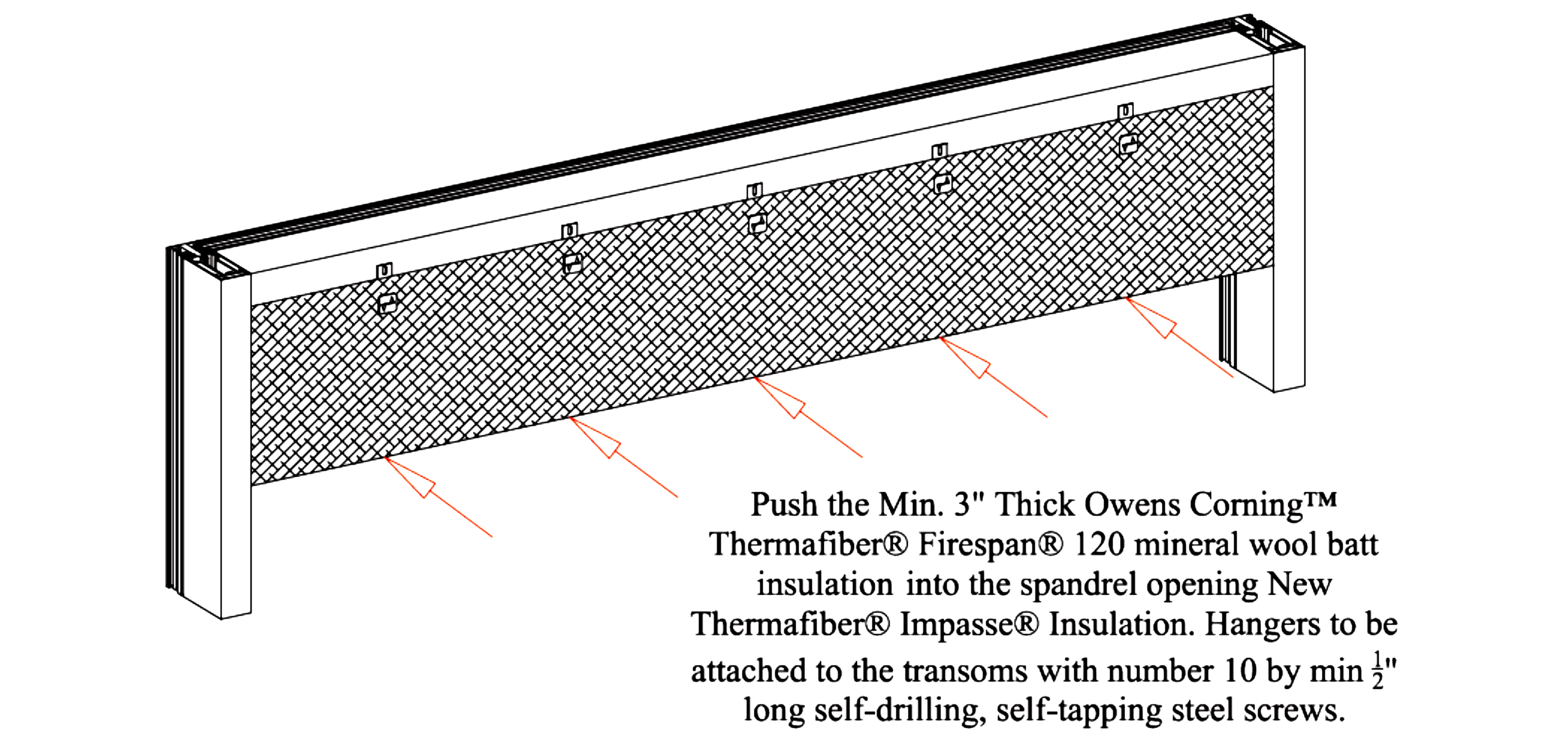

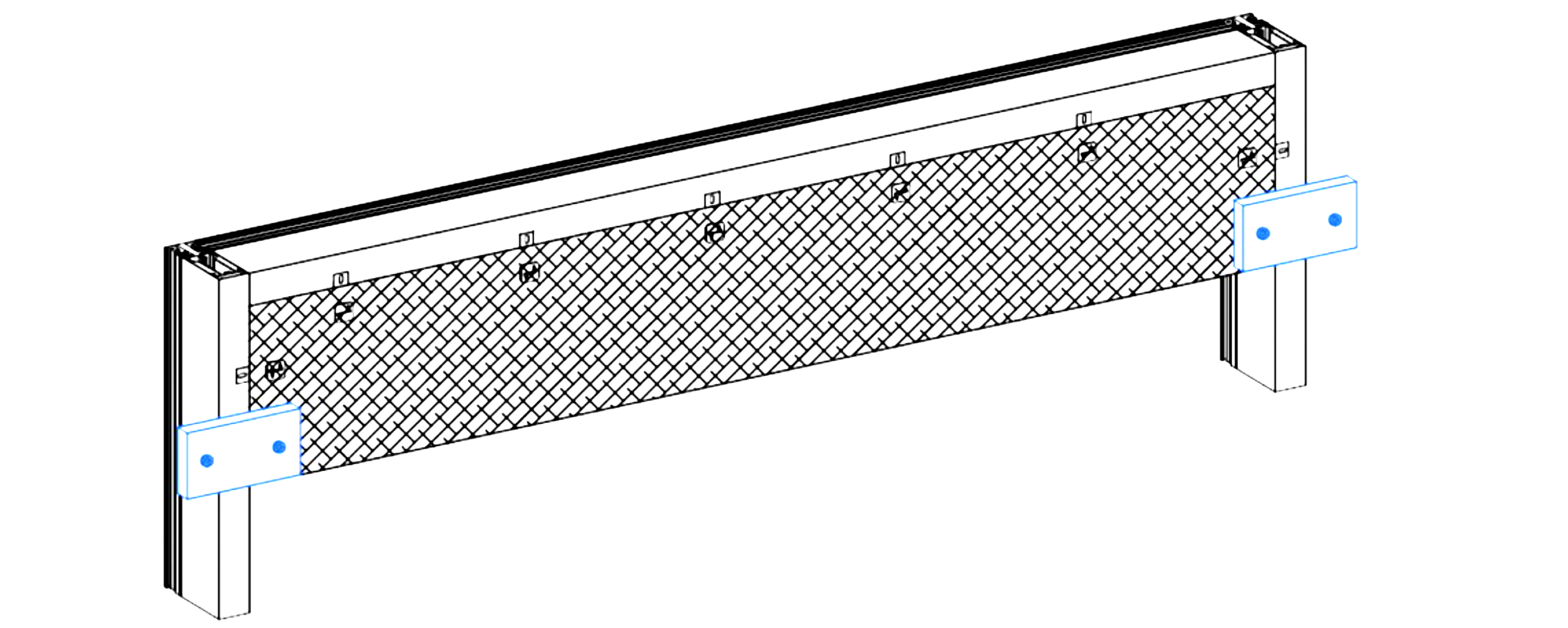

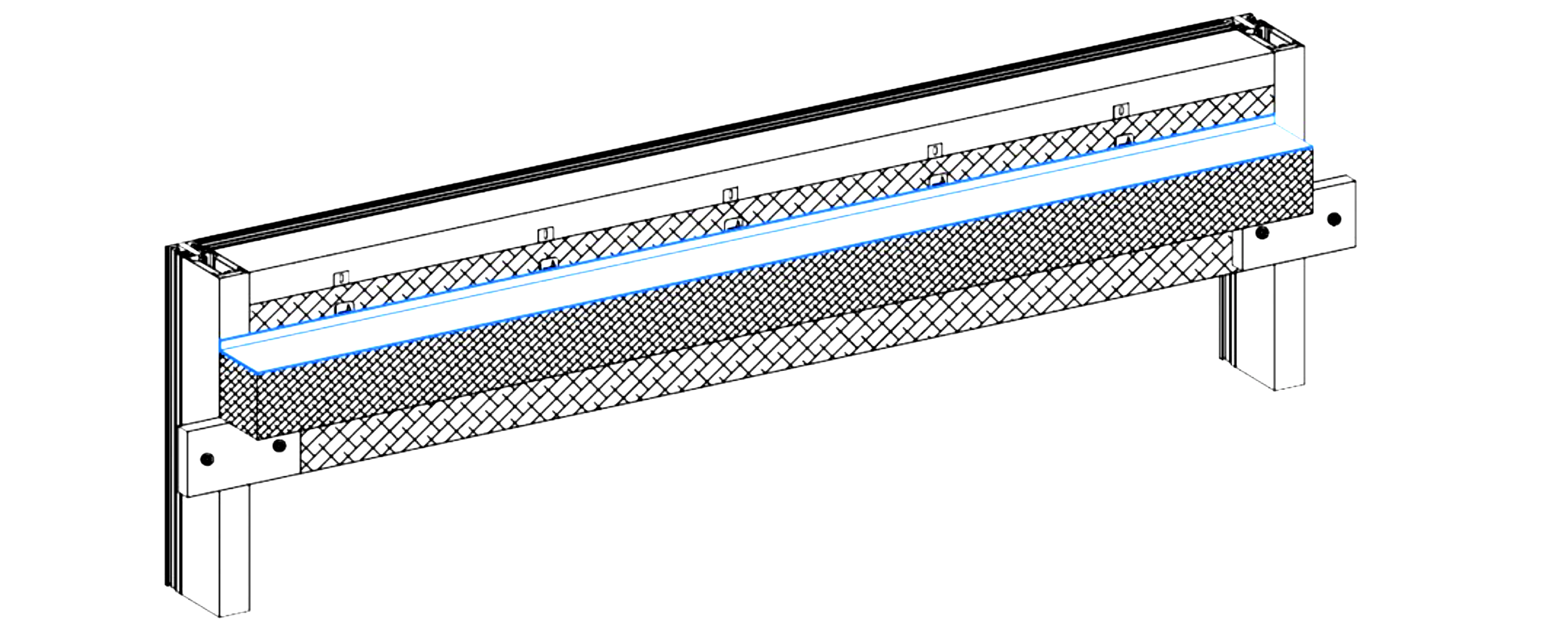

The Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System avoids common pitfalls that plague existing zero spandrel PFC systems. The arrangement revolutionizes the way zero spandrel systems are built with sturdier Thermafiber® FireSpan® 120 mineral wool insulation and innovative, heavier-duty Impasse® 2.0 Hanger technology. This robust system eliminates the need for costly and bulky back pans, accommodates various curtain wall anchors, allows for less penetrations in the curtain wall framing and offers flexibility for various shadowbox designs.

The Thermafiber® Impasse® Zero Spandrel PFC System allows for a quick install process, as additional framing support is not needed beyond the Impasse® 2.0 Hanger attachment system. Instead, the system combines durable, high-density insulation – Thermafiber® FireSpan® 120 – and heavy-duty, patented Impasse® 2.0 Hangers to support additional flexibility.

The assembly is code compliant with ASTM E2307 and does not have to rely on the E119 exception.

Simplifying the components

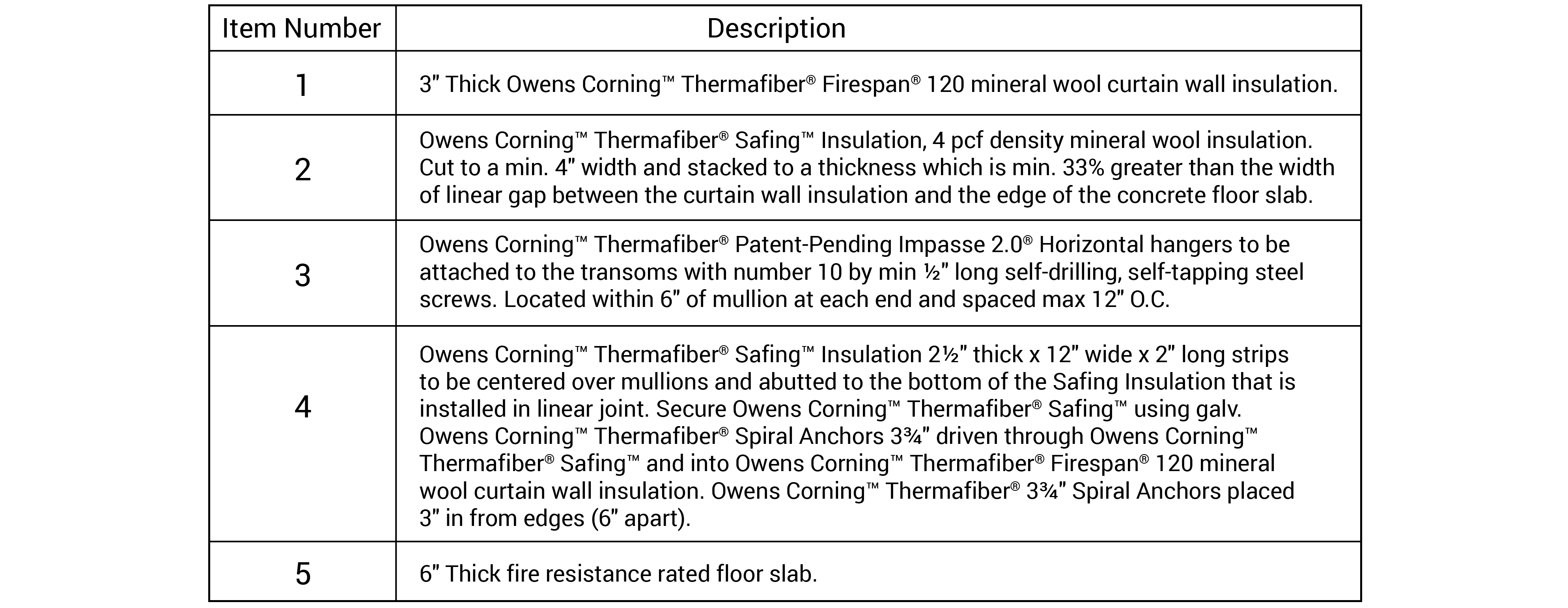

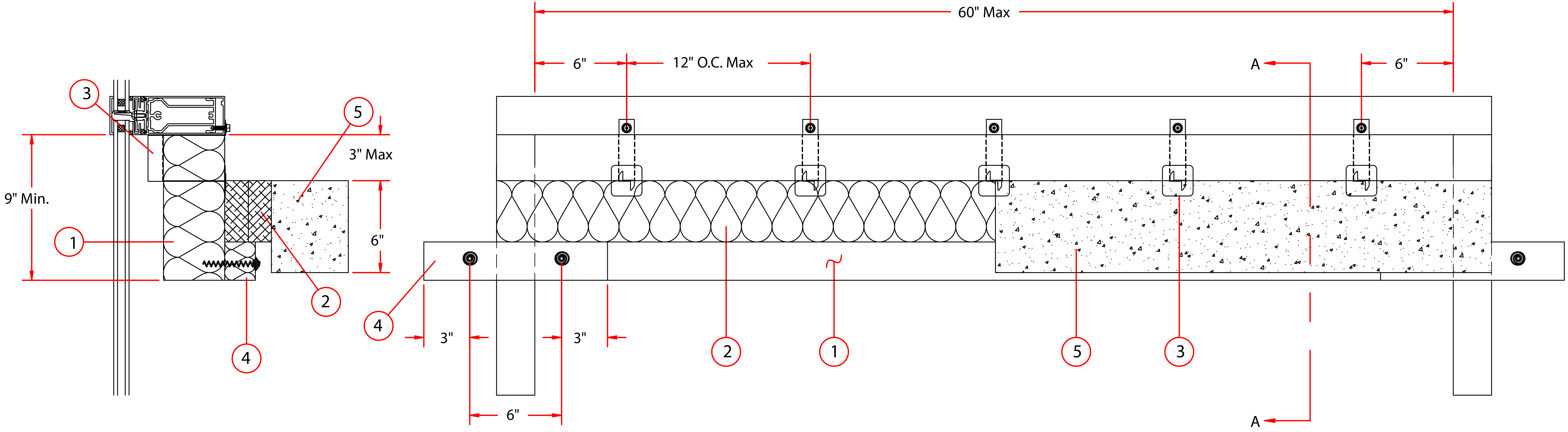

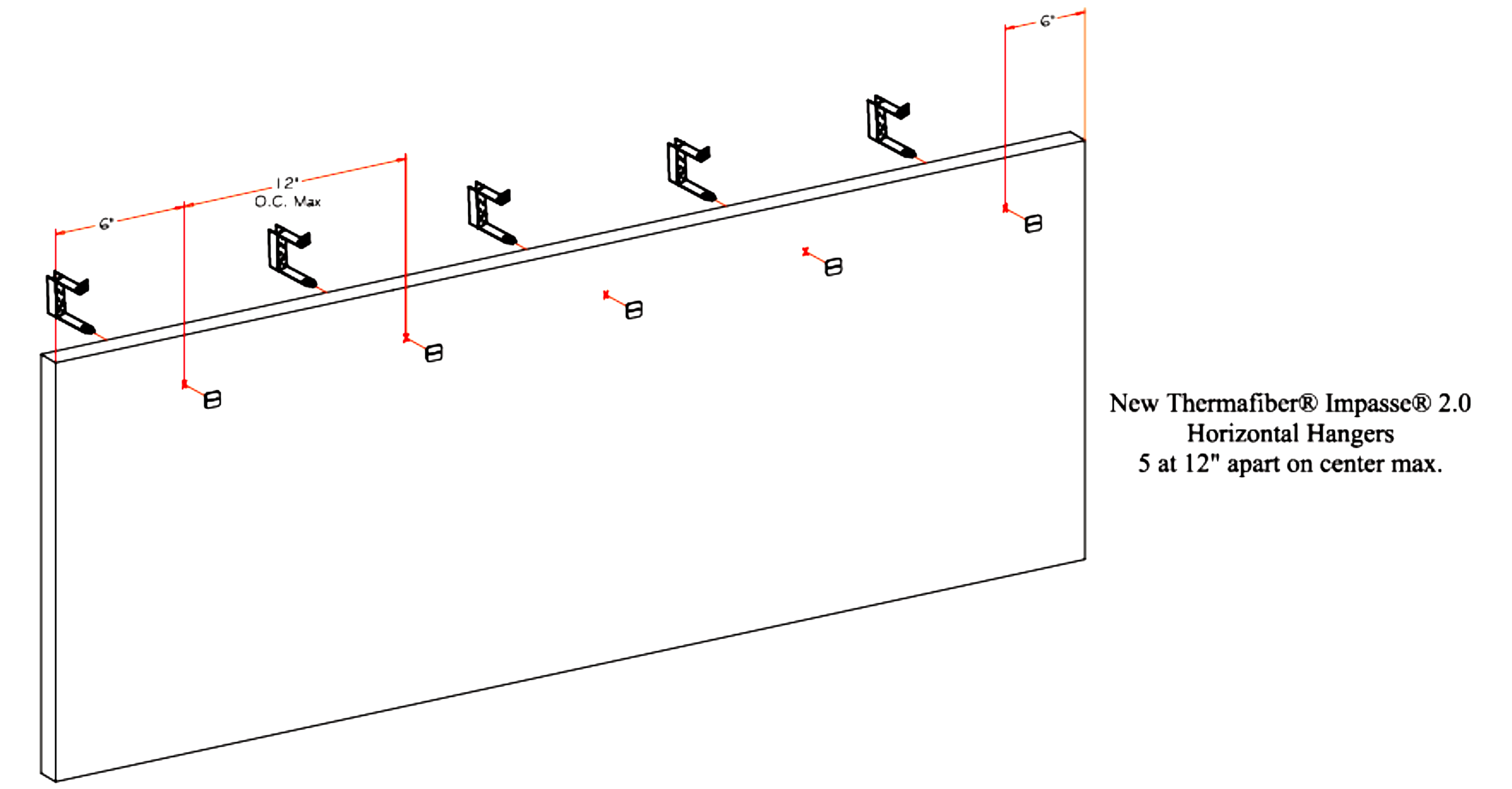

Components of our Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System simply include Thermafiber® FireSpan® 120 mineral wool insulation, Thermafiber® Safing, Thermafiber® Impasse® 2.0 Horizontal Hangers, Thermafiber® Safing insulation mullion protection and Thermafiber® Spiral Anchors.

The hanger system allows for attachment to the horizontal framing and is robust enough to support the more durable insulation. Mechanical attachment at the horizontal transom avoids interference with various types of curtain wall anchors versus existing zero spandrel systems. The innovative system design is easier to install because it requires less hangers and does not require a backer reinforcement member or silicone on the underside of the transom.

Thermafiber® FireSpan® 120 mineral wool insulation is a unique product, as it can be easily fabricated to fit around various types of curtain wall anchors and provides the same reinforcement characteristics as a steel back pan at a lesser cost. It is also available in a formaldehyde-free formulation. It is part of the Thermafiber® FireSpan® insulation product line, specifically designed to work in PFC systems.

During the installation process, Impasse® 2.0 Hangers are attached to FireSpan® 120 insulation and the insulation piece is installed into the spandrel opening. Mullion protection is then added, followed by safing insulation that is compression fit at the floor slab edge. The system can be installed either in the field or pre-installed in the shop. One unique feature versus other short spandrel system offerings is that the Thermafiber® Zero Spandrel System can be entirely installed from the floor above.

Conclusion

As designers continue to balance building aesthetics with fire safety, zero spandrel perimeter fire containment remains popular, despite the challenges of some systems. The new Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System meets design requirements and provides streamlined installation to deliver an effective PFC system. Contact us for an Engineering Judgment by emailing ThermafiberInsolutions@owenscorning.com.

References

- Reference Intertek® design listings: TFI/BPF 180-07 (3 hour F rating) and TFI/BPF 120-15 (2 hour F rating).

- ASTM International. (2020). Standard Test Methods for Fire Tests of Building Construction and Materials. (ASTM E119-20). Retrieved from https://www.astm.org/e0119-20.html.

- ASTM International. (2020). Standard Test Method for Determining Fire Resistance of Perimeter Fire Barrier Using Intermediate-Scale, Multi-story Test Apparatus. (ASTM E2307-20). Retrieved from https://www.astm.org/Standards/E2307.htm.

Related Articles

Related Articles

Fire • Commercial • BlogMineral Wool Wall insulation & Fire Safety

Fire • Commercial • BlogStone Wool Versus Slag Wool insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool insulation

Fire • Industrial • BlogCombustible Liquids in insulation

Fire • Industrial • BlogThe Behavior of Industrial insulation in Case of Fire

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite