- Moisture

- Industrial

- Blog

Using Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Blog in Brief

There are several factors to evaluate when designing an insulation system to protect metal pipes from the development of corrosion under insulation (CUI). For corrosion to take place, moisture needs to have entered the insulation system. When moisture is acidic in nature and/or temperatures are high, CUI can be accelerated. While there are several types of finishes that can help keep moisture from entering insulated systems, using an impermeable and non-absorbent insulation could be the simplest way to prevent moisture ingress. Looking beyond insulation selection there are two common ways to limit CUI development – keeping moisture from entering the insulated system and providing moisture a pathway out of the system. FOAMGLAS® cellular glass insulation can be used to mitigate CUI as it is closed cell, impermeable and non-absorbent. It also can be used in either a sealed system – to prevent moisture reaching pipes – or with a spacer system – designed to prevent moisture ingress and channel moisture away from pipes.

Using cellular glass insulation to mitigate corrosion under insulation (CUI)

On a global basis, damage caused by the development of corrosion is estimated to cost about $2.5 trillion annually.1 However, using currently available corrosion mitigation or reduction practices could help reduce that cost by 15-35%.1 When corrosion takes place under insulation, damage can be hidden out of sight until it leads to an unanticipated failure in the process. This can cause unexpected shutdowns or down time for a facility, expensive repairs, damage to other equipment, increased potential for leaks, system failure or site fire. CUI development can also pose a risk to employee and facility safety.

There are a few elements that contribute to the development of corrosion under insulation. A primary condition needed for CUI to occur is the presence of liquid moisture under the insulation in contact with the outer surface of the pipe. The temperature “danger zone” for corrosion development is between -4°C and 175°C (25°F and 350°F). Corrosion development can be accelerated at higher temperatures within this range or when the moisture present is highly acidic.

When the pipes being insulated are below this temperature range, liquid moisture within the system will tend to freeze. Conversely, at temperatures above this range, moisture that is present will turn into steam before coming into contact with the pipe. In both scenarios, corrosion will not immediately take place as liquid moisture is not present. However, if the systems were to experience shutdowns or cycle in temperature, liquid moisture can be reintroduced and lead to the risk for CUI to develop.

As liquid moisture is such a key ingredient for CUI to take place, preventative actions typically involve addressing the presence of it. These could include evaluating the type of insulation used, taking steps to prevent moisture from entering the system or planning a way to release moisture from the insulated system.

Insulation Material Selection

There are multiple ways that moisture can be present to interact with an insulated system – condensation, precipitation, process leaks, cleaning practices or deluge systems, cooling tower drift and the functioning of other systems like sprinklers.

Selecting an insulating material that is impermeable to liquids and will not absorb moisture can provide an additional layer of protection. A material like FOAMGLAS® cellular glass insulation is closed cell and non-absorbent, meaning it sheds water and will not collect moisture. When properly designed around, a material with this combination of properties can be a crucial component of a CUI mitigation strategy.

Keeping moisture out

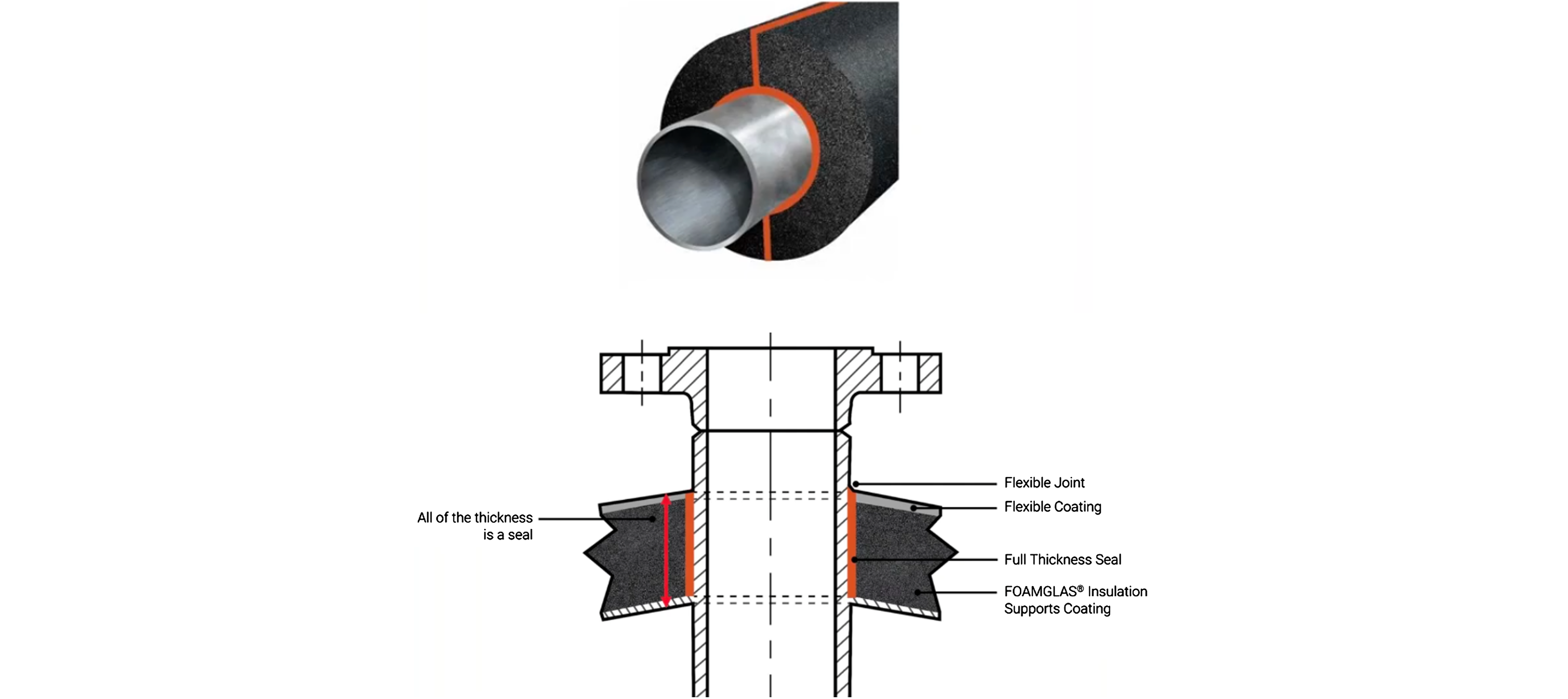

One way to prevent CUI from developing is to correctly install a sealed system intended to keep moisture from entering. The FOAMGLAS® sealed system can be used on below ambient pipes facing vapor drive challenges, in underground or direct buried applications, and in above ambient conditions especially when temperature cycling will occur. This system pairs closed cell cellular glass insulation with a proprietary joint sealant to prevent moisture from finding a path to reach the underlying pipes. The use of sealant, such as PITTSEAL® HI-TEMP LV RTV, functions to protect against moisture intrusion at critical locations, such as joints, extrusions or terminations.

Figure 1– FOAMGLAS® Sealed System with proprietary joint sealant technology.

PITTSEAL® HI-TEMP LV RTV sealant was formulated for use with FOAMGLAS® cellular glass insulation and can be applied in a manner similar to joint sealant on cold systems. It has a low viscosity and uses a neutral cure process. The sealant also has a wide temperature range -150°C to -232°C (-238°F to 450°F). Joint sealant should be applied evenly across the full depth of insulation mating surfaces.

Allowing Moisture a Way Out

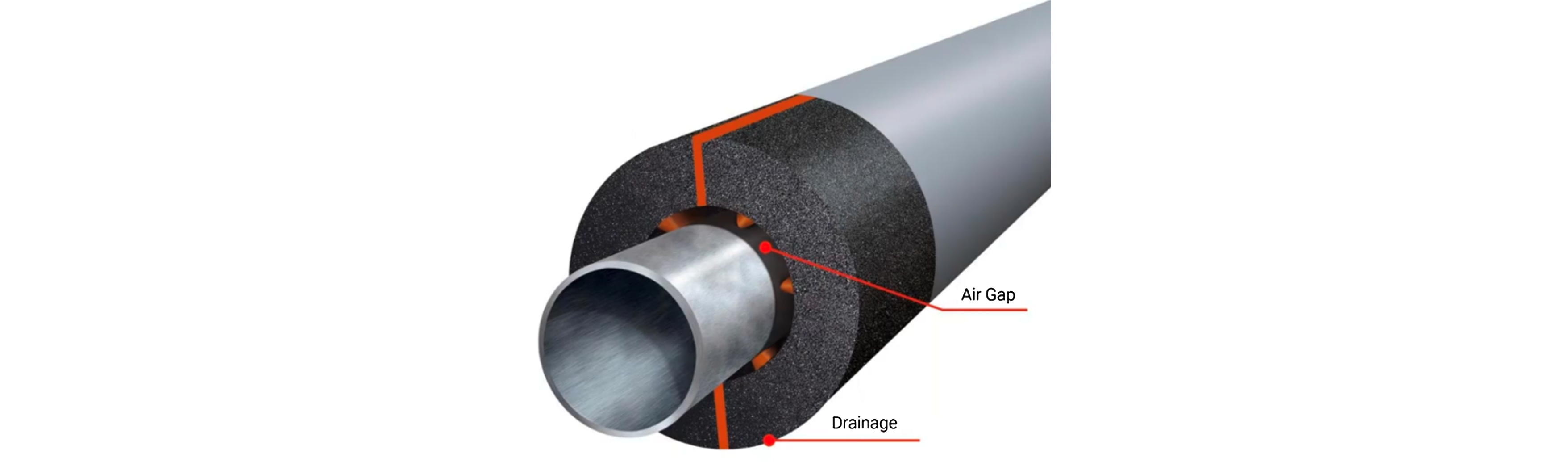

Another way to prevent CUI is by providing moisture that does enter the system a path to exit. The FOAMGLAS® spacer system uses a proprietary spacer technology to create an air pocket between the piping and insulation. This gap allows for moisture to channel along the inner bore of the insulation, away from the piping surface. A series of drainage holes are then cut into the bottom of the insulation, allowing moisture to drain out of the system. In addition to spacers, termination strips are introduced at strategic locations to compartmentalize the system and limit moisture travel. This system also utilizes PITTSEAL® HI-TEMP LV RTV sealant to seal against water intrusion at critical locations mentioned above.

The spacer insulation system is intended for use on ambient or hot piping systems with continuous or near continuous operation. Due to the drainage holes, this system is not recommended on below ambient, direct-buried, or hot and cold cycling systems.

Figure 2 – FOAMGLAS® spacer system with proprietary spacer technology.

Conclusion

There are several considerations to make when designing a system to protect piping from moisture and the development of CUI. These considerations include the insulation material type, accessories to be used, and a strategy around moisture control. The FOAMGLAS® sealed system and FOAMGLAS® spacer system can help mitigate the risk of CUI, protecting the long-term function of piping and equipment.

Watch a video about using the FOAMGLAS® sealed system, or get more information on implementing the spacer system to protect your pipes. Finally, here is a video with more information on the benefits of using impermeable insulation.

References

Related Articles

Related Articles

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Jump to a Solution Suite

Jump to a Solution Suite