- Fire

- Industrial

- Blog

Combustible Liquids in Insulation

Blog in Brief

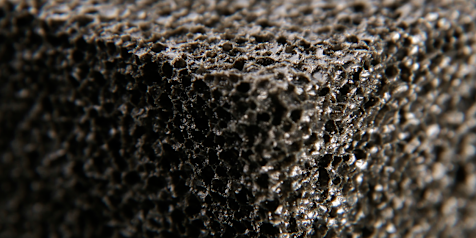

Risk of fire increases when combustible liquids, such as oils and heat transfer fluids, are absorbed by insulation materials (also called “wicking”). Even certain non-combustible insulation materials can absorb combustible liquids and, consequently, contribute to the spreading of a fire.

Under certain conditions, combustible liquids can ignite even without the presence of an open flame. Slow oxidation may result in temperature buildup within saturated insulation, and, finally, combustion. As a result, system engineers often specify non-absorptive, non-combustible cellular glass insulation systems for applications with a risk of leaking organic fluids.

Cellular glass insulation is also recommended for low temperature applications. One reason is to minimize the potential danger of condensed gases that would otherwise be soaked up by absorbent insulations, should they escape the system.

Possible problems

Absorbent insulation materials can create a serious fire hazard due to their ability to retain large quantities of combustible liquids when a system leak occurs. Insulation that becomes saturated in this manner can become a serious threat to personnel, property and production.

Should a combustible liquid be allowed to leak into an absorbent insulation, it can permeate throughout the thickness and sit idly as a dormant mass of fuel. Due to the presence of insulation jacketing, this risk can often go undetected for months or even years, until a source of ignition is introduced to the environment, which can lead to explosive combustion of the saturated insulation.

Fires caused by absorption of flammable liquids into insulation have occurred with a variety of liquids, such as lubricating oil and hydraulic fluid in power stations and ship engine rooms. Other potentially dangerous liquids and gases include heat transfer fluids, chemical intermediates, resins, solvents, vegetable oils, silicones, fatty acids, explosives and oxidizers.

The danger posed by auto-ignition

Many heat transfer fluids have auto-ignition temperatures near or in excess of 1000°F (538°C). However, through oxidation, they can decompose into various by-products. Some of these by-products may exhibit new auto-ignition temperatures that are far lower than the original fluid. This means that oxidation has the potential to lower the temperature threshold at which auto-ignition becomes a concern.

Additionally, oxidation is an exothermic reaction, meaning it generates heat as it takes place. Normally this heat generated is quickly lost to the surroundings. However, when occurring within the low thermal conductivity of insulation materials, it can can lead to a significant and slow heat buildup within the thickness of the saturated insulation. This heat generated, paired with a potentially lower auto-ignition point as described above, can yield a scenario primed for ignition to occur. Should the insulation jacketing be removed or opened up at some point in the future, such as for maintenance activities, the fluid would be exposed to an abundant supply of new oxygen. In the worst-case scenarios, this could lead to auto-ignition of the saturated insulation.

Oils used for lubrication, fuel and hydraulics can cause similar auto-ignition actions. The auto-ignition temperatures for oils, however, are much lower than those for heat transfer fluids. In fact, studies of oil-soaked lagging fires have found occurrences of ignition at operating temperatures as low as 176°F (80°C). Despite this, many specifiers are less aware of the potential dangers with oils as compared to transfer fluids.

Lower auto-ignition temperatures also occur with gases. For example, ethylene oxide, which normally has an ignition point of 1060°F (571°C), was found to have a much lower ignition point after being absorbed by porous insulation materials.1

Wicking test with calcium silicate, microporous silicate and perlite.

Leak sources

Most major leaks result from component failure. Expansion joints, leaky valves, equipment flanges and areas where insulation is in contact with flat surfaces are among the critical points that collect and absorb leaked chemicals.

These areas should receive extra attention when insulating heat transfer pipework. System engineers recommend always using cellular glass insulation for these critical points.

Non-combustibility

Above Ambient Systems

Prefabrication and ease of inspection

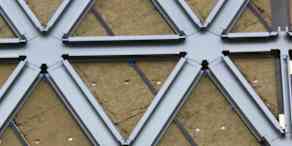

For both vessel and pipeline applications, FOAMGLAS®cellular glass insulation can be prefabricated, including pre-applied finishes, for efficient, time-saving installation and inspection.

Related Articles

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite