Fiberglass Board Insulation for Mechanical SolutionsIndustrial insulation that saves energy and reduces noise

Industrial insulation that saves energy and reduces noise

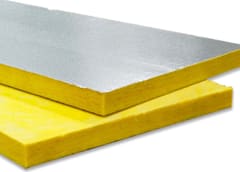

The Owens Corning Fiberglas™ Fabrication Board Insulation is made of inorganic glass fibers with a thermosetting resin binder formed into rigid rectangular boards. The boards are used for the fabrication of insulation fittings, precision cut pipe, v-groove board, and pipe & tank wrap insulation. It conserves energy, maintains process temperatures, provides personnel protection, helps prevent condensation, and reduces noise emission and transmission.