- Fire

- Industrial

- Blog

Fire testing takeaways to consider when selecting insulation for fire protection

Blog in Brief

In addition to providing thermal protection for piping and storage containers at petrochemical and hydrocarbon processing and handling facilities, insulation can be used to provide passive fire protection in the event a fire occurs. There are several factors to consider when deciding how to design a passive fire protection system, including which components at the facility need to be protected, the use and qualities of the materials used, and the types of protection needed. Insulation selected for passive fire protection should be able to provide a sufficient amount of protection based on what is specified for the application. Materials employed should also not burn, generate smoke or spread flame. Additionally, multiple layers or different types of insulation may be utilized to provide the full range of specified protection, both in terms of meeting operational requirements and providing passive fire protection. Insulation materials like FOAMGLAS® cellular glass insulation and Thermafiber® mineral wool insulation have been tested for their fire resistance attributes and ability to provide protection should a fire occur at a facility.

Importance of passive fire protection

Steel alloys used in structural steel components will lose roughly 50% of their load-bearing capacity when heated to 538°C (1,000°F). Should a fire occur at a petrochemical facility, structural steel elements become at risk of collapsing and releasing hazardous materials into the area. Additionally, hydrocarbon facilities often contain volatile materials that are kept in liquid form at low temperatures. If allowed to rapidly heat, these materials can quickly evaporate, causing pressure buildup and explosive hazards in the vessels that contain them. For these reasons, any fire that takes place within these facilities poses an immediate safety concern for all personnel within the area. Passive fire protection systems are designed to prolong this period of temperature rise for key elements, allowing time for equipment to be shut down, personnel to safely escape and firefighting services to arrive.

Takeaways to consider when selecting insulation for fire protection

Before insulation can be used to provide passive fire protection, there are series of tests to examine distinct characteristics of the material and the amount of protection provided.

Tests used to evaluate insulation for combustibility include ASTM E136 – Behavior of Materials in a Vertical Tube Furnace at 750°C (1,382°F) – and EN 13501-1 – Fire Classification of Construction Products and Building Elements. These tests evaluate the combustibility and heat production characteristics displayed by different building materials. Both tests involve heating the materials until thermocouples reach 750°C (1,382°F) or the specimen fails. Throughout the tests, visual observations are made to establish flame- and smoke-related behavior. A material is considered to have passed ASTM E136 or EN 13501-1 when the surface and internal thermocouples do not rise more than 30°C (54°F) above the stabilized furnace temperature, there is no flaming of the specimen after 30 seconds into the test or at any time during the test and the weight loss of the test specimen is less than or equal to 50%. The tests can be used to classify an insulation as noncombustible according to ASTM E136 or as Class A1 or Class A2 noncombustible according to EN 13501-1. These two international test methods are not considered equivalent or interchangeable. It is possible, however, for materials to earn both ratings. For example, FOAMGLAS® cellular glass insulation has been tested to both standards and is classified as noncombustible – ASTM E136 – and Euroclass A1 – noncombustible – EN 13501-1.

Another material-focused test is ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials. The test evaluates flame spread and smoke generation compared to standard materials. In the examination, the material is placed in a horizontal furnace and burners direct flame against it. Initial readings are then taken and photoelectric cell output is monitored. At the end of the test, the flame spread distance, temperature and change in photoelectric cell readings are plotted.

When tested according to ASTM E84, FOAMGLAS® cellular glass insulation block was found to have a flame spread index and smoke developed index of zero.

There are also two common insulating system-focused tests used to understand how insulation systems will function when exposed to two different types of hydrocarbon fires – UL 1709 – Rapid Rise Fire Tests of Protection Materials for Structural Steel – and the “jet fire” test ISO 22899-1 – Determination of the Resistance to Jet Fires of Passive Fire Protection Materials – Part 1 – General Requirements.

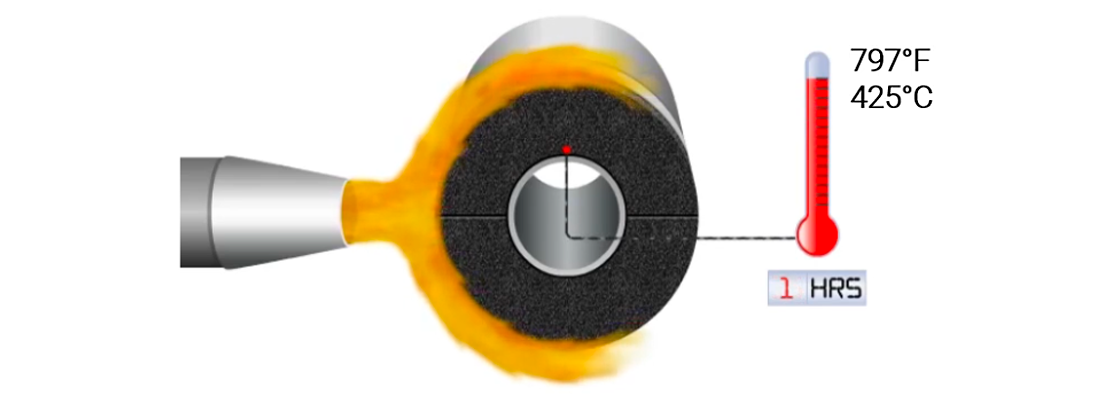

The UL 1709 test simulates a rapid rise in temperature resulting from a fire at a petrochemical facility. Insulating materials are used to protect an ambient temperature structural steel beam, steel pipe or steel tube during a simulated hydrocarbon fire exposure. The temperature of the insulated substrate is monitored throughout the test using multiple groupings of four thermocouples. The furnace used to provide the fire exposure reaches 1,093°C (2,000°F) in the first five minutes and remains at that temperature for the duration of the test. The materials being tested earn a time-based rating depending on how long each takes to reach the failure point. Failure is defined as the point when a grouping of thermocouples reaches 538°C (1,000°F) or when any single thermocouple reaches 649°C (1,200°F).

The jet fire test examines a material or insulating system’s response to a high-velocity jet fire, which is considered a significant risk in the oil and gas industry. The insulation is exposed to a 14 megawatt (0.3kg/sec) directional flame generated by a propane fuel system for differing periods of time. The temperature of the underlying item is then monitored.

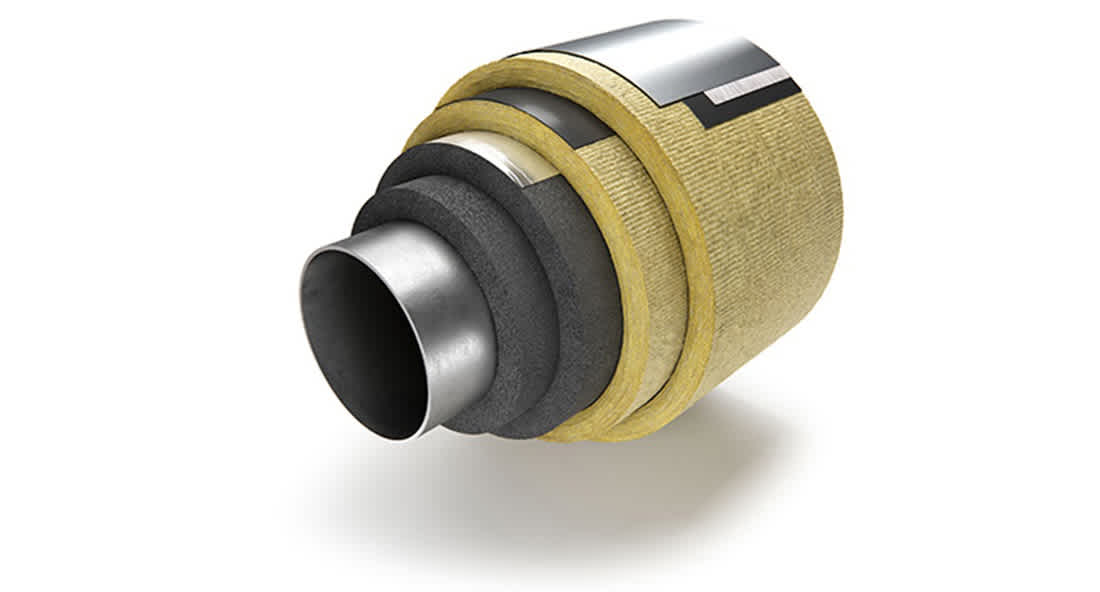

FOAMGLAS® cellular glass insulation has been tested according to both UL 1709 and ISO 22899-1. Testing considered the insulation in single layer, double layer and as a combination system with other materials, such as Thermafiber® mineral wool insulation.

Takeaway #1 – Insulation offers dual benefits

In industrial settings, thermal insulation is primarily used to reduce the rate of heat transfer on below ambient, ambient (freeze protection) or above ambient piping, tanks and equipment. Thermal insulation reduces energy usage and helps maintain systems at the desired temperature. When used to insulate piping, tanks and other equipment at facilities that have hydrocarbons or other flammable chemicals present, thermal insulation can also be a way to provide passive fire protection. This can allow additional time and protection for employees and facilities if a fire occurs. When acting as passive fire protection, insulation is assessed for how well it slows down thermal transfer or how much additional time it takes for the item being insulated to gain heat. Both UL-1709 and the jet fire test discussed above demonstrate the amount of protection provided during a hydrocarbon fire.

When insulating process piping or hydrocarbon and petrochemical storage tanks, designers must consider the need for passive fire protection for the system and for associated structural steel. When heated to 538°C (1,000°F) or beyond, steel alloys may lose 50% or more of their load-bearing capacities. This risk of reduced structural integrity increases the importance of passive fire protection for critical infrastructure in facilities where there is a risk of fire occurring.

Protecting structural elements may allow them to function longer, providing more time for facility employees to exit and emergency responders to address the situation.

Takeaway #2 – Material performance and environmental applications matter

There are several factors that should be considered when designing insulation systems, both in terms of controlling heat flow and as part of a facility’s passive fire protection system. Potential insulating materials should be chosen for their performance qualities and for their fire protection properties. Site-specific considerations must be included in the insulation system design. This not only includes system operating temperatures, but also environmental factors. For example, ambient and above ambient piping may not require the same thermal insulation thickness as below ambient piping in high humidity conditions, but all of these systems may require similar amounts of insulation to provide suitable levels of fire protection. Among other possible factors to consider is noise reduction. If noise reduction is a primary concern, a mineral wool-inclusive system could be a suitable approach. If flammable liquid absorption by the insulation system is a concern, the use of closed-cell cellular glass insulation may be an ideal solution.

Before selecting an insulation material as a component in a system intended to reduce heat flow and provide passive fire protection, it is important to consider if the insulation itself is combustible, if it will propagate fire, if it generates smoke when exposed to flame or if it will absorb combustible liquids. FOAMGLAS® cellular glass insulation is an inorganic closed-cell insulation that provides constant thermal efficiency and is resistant to fire. FOAMGLAS® cellular glass insulation will not generate smoke, does not burn and will not wick or absorb liquids – including flammable hydrocarbons. Inorganic Thermafiber® mineral wool insulation can resist high temperatures and is fire resistant.

Takeaway #3 – Materials can provide multiple types of protection

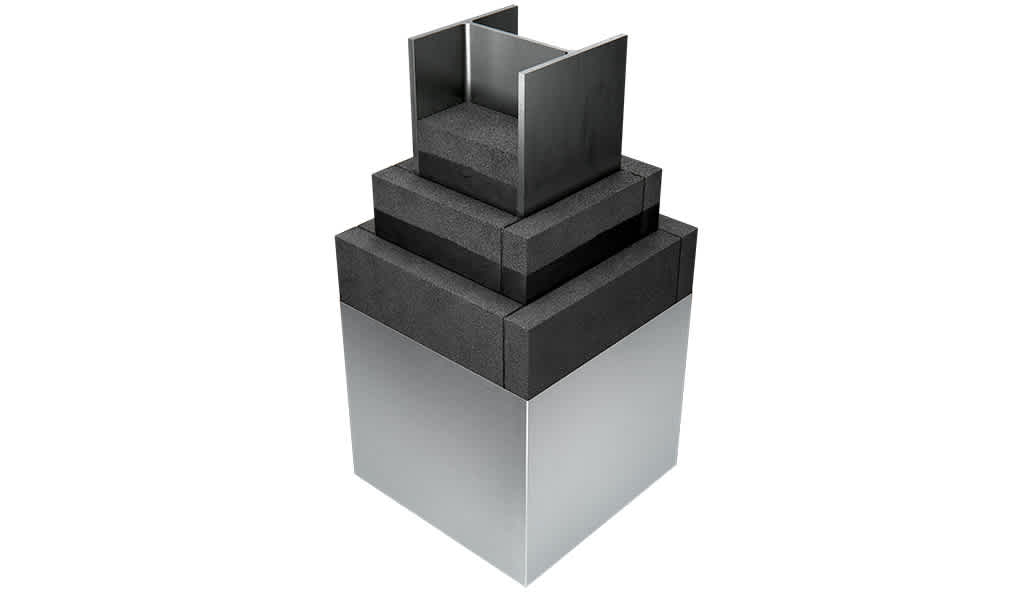

The nature of the facility and the type of materials being housed or processed on-site dictate the materials used for fire protection. Combining different insulation materials can be a way to take advantage of the best attributes of each product. Using a combined insulation system can address additional system requirements in addition to providing passive fire protection.

When used alone, insulating materials, like cellular glass insulation or mineral wool, can provide suitable fire protection to process piping and infrastructure. But by adding additional layers or combining insulating materials, the resulting insulation system may provide other benefits as well, including reduction of industrial noise.

It is recommended that insulation systems intended for use as protection against fire be either tested or modeled to verify that they can provide the passive fire protection times claimed by the manufacturer.

Conclusion

There are several test methods that can be used to predict how well an insulation will perform in a fire exposure situation. These test methods are designed to look at both properties of the insulation material and how well it performs as part of a system in simulated fire situations. Testing has demonstrated that FOAMGLAS® cellular glass insulation is nonflammable, nonabsorbent and does not spread flame or produce smoke. FOAMGLAS® insulation can be utilized in insulation systems that provide protection against rapid-rise fires or jet fires, depending on the insulation system configuration and thickness.

More information on fire testing practices used to evaluate materials or insulating systems is available here. Find more information on FOAMGLAS® use in passive fire protection.

Related Articles

Related Articles

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Industrial • BlogCombustible Liquids in Insulation

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Jump to a Solution Suite

Jump to a Solution Suite