- Moisture

- Industrial

- Blog

Specifying Insulation to Support Longevity in Chilled Water Systems

Blog in Brief

Energy prices remain volatile, and recent extreme weather events have spotlighted the importance of reliable infrastructure, showing how essential assuring the integrity of piping systems — including chilled water pipes — has become. Water ingress is an ongoing threat to chilled water insulation systems, particularly in humid environments or in settings with a high vapor drive. Alec Cusick a technical lead at Owens Corning, shares how taking a proactive approach to mitigating potential risks can help defend against challenges and support the longevity of a chilled water piping system.

Why Is It Important to Consider Pipe Insulation Early in the Chilled Water Design Process?

Keeping liquid and vapor moisture away from chilled pipes and preventing it from infiltrating the insulation are essential steps to ensuring the longevity of an insulating system. Decisions made at the design stage can help protect the sustained thermal efficiency of the insulating material. In addition, those decisions will support the proper functioning of the chilled piping processes and reduce the risks of hazards resulting from a system failure.

Any breach of the insulating system could result in increased energy costs, damage to piping, or increased stress on equipment because it must work harder to bring chilled water lines back to operating temperature. By properly designing and installing insulation, designers can help ensure that the system delivers efficient thermal performance, reducing the chance that insulation will need to be replaced earlier than expected.

What Challenges Are Common with Chilled Water Piping Systems?

Moisture infiltration — whether liquid or vapor — is the primary risk for chilled water systems. The temperature of chilled water supply lines is typically lower than ambient conditions — about 36°F (2.2°C). The temperature for system return lines is commonly 50 to 55°F (10 to 12.7°C). This lower surface temperature means there often will be a constant vapor drive that wants to move moisture present in the air to the cold pipe. If the temperature of the pipe happens to be colder than the surrounding air’s dewpoint, this can result in condensation forming along the pipe’s surface within the insulation system.

In What Other Ways Might Moisture Enter an Insulation System?

Every chilled water piping system is unique, and indoor and outdoor systems will face different challenges when it comes to defending against the risks moisture presents.

As noted earlier, vapor drive is a common way that moisture enters an insulation system, but it is not the only way. If the thickness of the insulation installed is insufficient, or if the insulation’s thermal resistance becomes compromised, it can result in a surface temperature on the insulation that is colder than the dewpoint. This can allow surface condensation or “sweating” to occur on the outside of the insulation system rather than within.

In outdoor or below-grade installations such as direct buried systems, precipitation and groundwater could find their way into the system through any openings in the system’s vapor barrier.

What Are Some Warning Signs of Moisture Infiltration?

Dripping water is one of the most noticeable indicators of a problem with chilled water pipes. Drips could indicate the formation of condensation on the insulation or suggest that the insulating material itself has been saturated. In general, if dripping water is observed from a chilled water line, the insulation system should be inspected.

What Are Common Problems Associated with Moisture Infiltration?

Moisture can lead to several problems when introduced to chilled water insulation systems. Water that drips from piping can cause unpleasant staining to ceiling tiles or collect on the floor, becoming a slipping hazard. Additionally, the presence of moisture provides a key ingredient for the formation of mold and mildew, which could present concerns for a building’s indoor air quality.

Another potentially costly consequence is the development of corrosion under insulation (CUI) on the metal pipe surface. CUI can shorten the life of a piping system and lead to costly downtime and maintenance.

Thermal performance also can be reduced when moisture enters an insulation system. Studies have demonstrated water can conduct heat 10 to 30 times more efficiently than air.1,2 When an insulating system experiences a reduction in thermal performance, process control suffers because chilled lines more rapidly warm up to ambient temperature. Additional strain then is placed on the chillers because they require more energy to return chilled water lines to the desired temperature. And, of course, this increased energy consumption will result in higher energy costs for the building.

How Do Environmental Factors Affect Insulating Systems on Chilled Water Piping Systems?

A facility’s geographic location is an important factor to consider when designing insulation systems for chilled water piping. Because humidity varies with climate zone, it is important to note the environmental conditions where a system will be installed. Southern or coastal areas that experience increased humidity levels will present a higher vapor drive toward cold piping surfaces. This increases the amount of insulation thickness needed to prevent surface condensation from occurring. It also places more emphasis on the system permeability during the design phase to avoid allowing vapor drive to force moisture into the system.

Even in indoor environments, unique circumstances of a building’s functions may pose challenges for chilled water lines. In an airport, for example, multiple gate openings and large sliding entryways can allow external air to infiltrate the enclosure and raise relative humidity. A situation like this can increase an environment’s dewpoint and accelerate the vapor drive toward cold surfaces, increasing the risk of condensation forming. Other types of buildings such as schools may close for long periods throughout the year. When these buildings are shut down or idled, chilled water lines may be left operational even as air handlers are turned off. The combination of warm, humid air and chilled piping surfaces can create a strong vapor drive toward the cold surfaces of chilled water pipes. This is often referred to as “idle-building syndrome” and should be considered during the design phase of a chilled water system to avoid complications in the future.

What Material Science and Performance Factors Should Be Considered When Selecting Insulating Materials for Chilled Water Pipes?

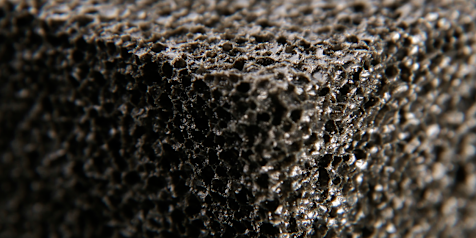

An insulation material’s permeability is worth considering for a chilled water system, especially in areas of particularly high humidity and vapor drive. Permeability is a measure of a material’s tendency to allow liquids or gases to pass through it. Open-cell insulations tend to have higher permeability values than closed-cell insulation materials. High-permeability insulations rely solely on the performance of an external vapor barrier to resist moisture ingress into a system. If that vapor barrier were to become compromised, either due to poor installation or damage while in service, water vapor can freely move into the insulation and onto the piping surface, where it can begin condensing as liquid water.

In contrast, closed-cell insulating materials tend to have lower permeability values. Insulating materials with a near-zero permeability value will be more inherently resistant to moisture migrating into the system. In locations involving high vapor drive, this can play a large role in a system’s longevity over time.

Besides Insulation, What Other Elements of the Insulating System Should Be Considered?

The emissivity of an insulation’s outermost jacketing material is yet another important consideration when it comes to designing chilled water systems. Emissivity is an indicator of how effectively a material emits and absorbs heat by radiation, and it is most relevant to the insulation system’s outermost surface. It is expressed as a ratio between 0 and 1. The higher the emissivity number, the more heat will be able to transfer between the material and the surrounding environment.

The emissivity of a jacketing material can have a noticeable influence on the surface temperature of an insulation system. In warm environments, low emissivity materials like aluminum or steel will absorb less heat from the external environment via radiation, which results in a lower jacketing surface temperature. In contrast, a high emissivity jacketing like PVS or ASJ absorbs more heat from the surroundings via radiation, resulting in a higher surface temperature. In certain environments, this difference can dictate whether an insulation system experiences surface condensation or stays dry.

What Is an Example of an Insulation Material Suitable for High Vapor-Drive Environments?

Cellular glass insulation is one example of a closed-cell insulation material commonly specified on chilled water systems where high vapor-drive is a concern. Cellular glass insulation is unique in that it has a permeability rating of zero and does not absorb liquid or vapor moisture. When paired with a compatible joint sealant, it can be used to achieve a fully sealed system to resist moisture ingress for many years even in high humidity environments.

Conclusion

A proactive approach that considers operating temperature, the climate zone of a facility and any worst-case scenarios is a good strategy when it comes to designing insulation systems for chilled water piping.

References

- Lubinski, R. 2015. “Chilled-Water Piping Condensation Control for Energy Savings and Risk Avoidance.” Insulation Outlook. https://insulation.org/io/articles/chilled-water-piping-condensation-control-for-energy-savings-and-risk-avoidance/. Retrieved August 1, 2023.

- Owens Corning. 2020. “The Impact of Moisture in Chilled Water Insulation Systems,” (technical newsletter).

- Gusyachkin, A.M., et al. 2019. IOP Conference Series: Material Science and Engineering. 570 012029.

- Brayman, B. J. 2017. “Case Study: Remediating Chilled-Water Pipe Insulation at a Football Stadium and Convention Center.” Insulation Outlook. Retrieved from https://insulation.org/io/articles/case-study-remediating-chilled-water-pipe-insulation-at-a-football-stadium-and-convention-center/.

- ANSI/ASHRAE/IES Standard 90.1 — 2019, Energy Standard for Building Except Low-Rise Residential Buildings. https://www.ashrae.org/technical-resources/bookstore/standard-90-1.

- As established by testing according to EN 1 604 and ASTM E 228.

Related Articles

Related Articles

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Jump to a Solution Suite

Jump to a Solution Suite