CAUTION: DO NOT MIX MATERIAL BEARING DIFFERENT LOT NUMBERS, REFER TO THE LOT NUMBERS LOCATED ON THE SIDE OF THE BUNDLE

Application Instructions

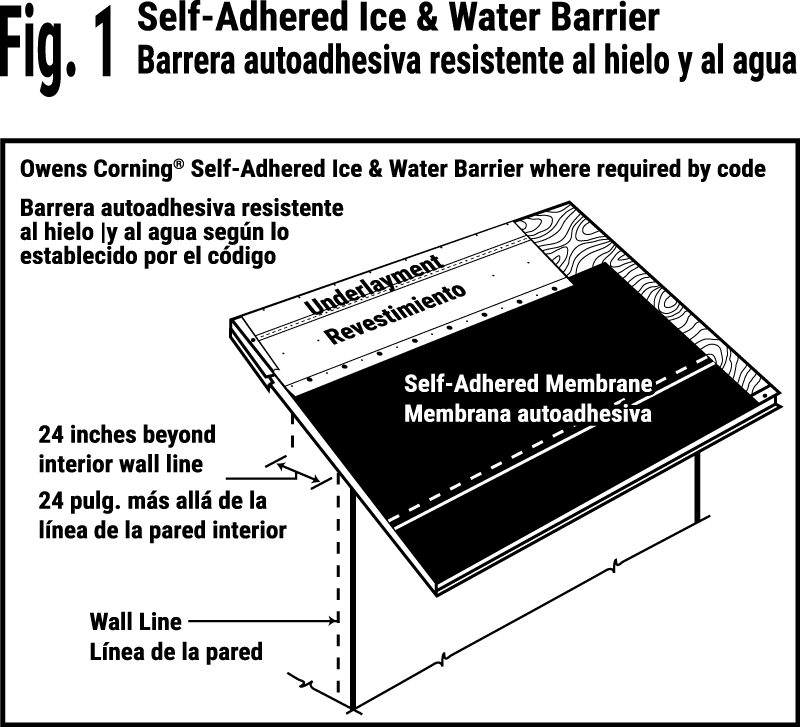

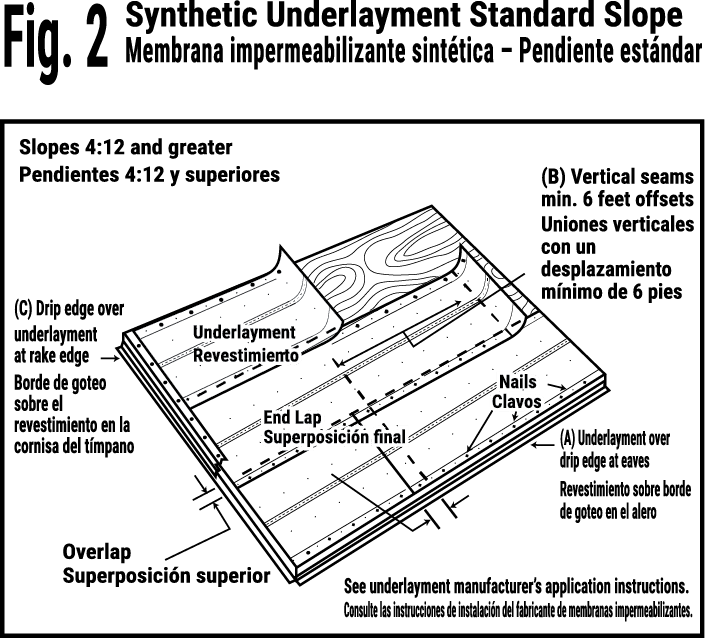

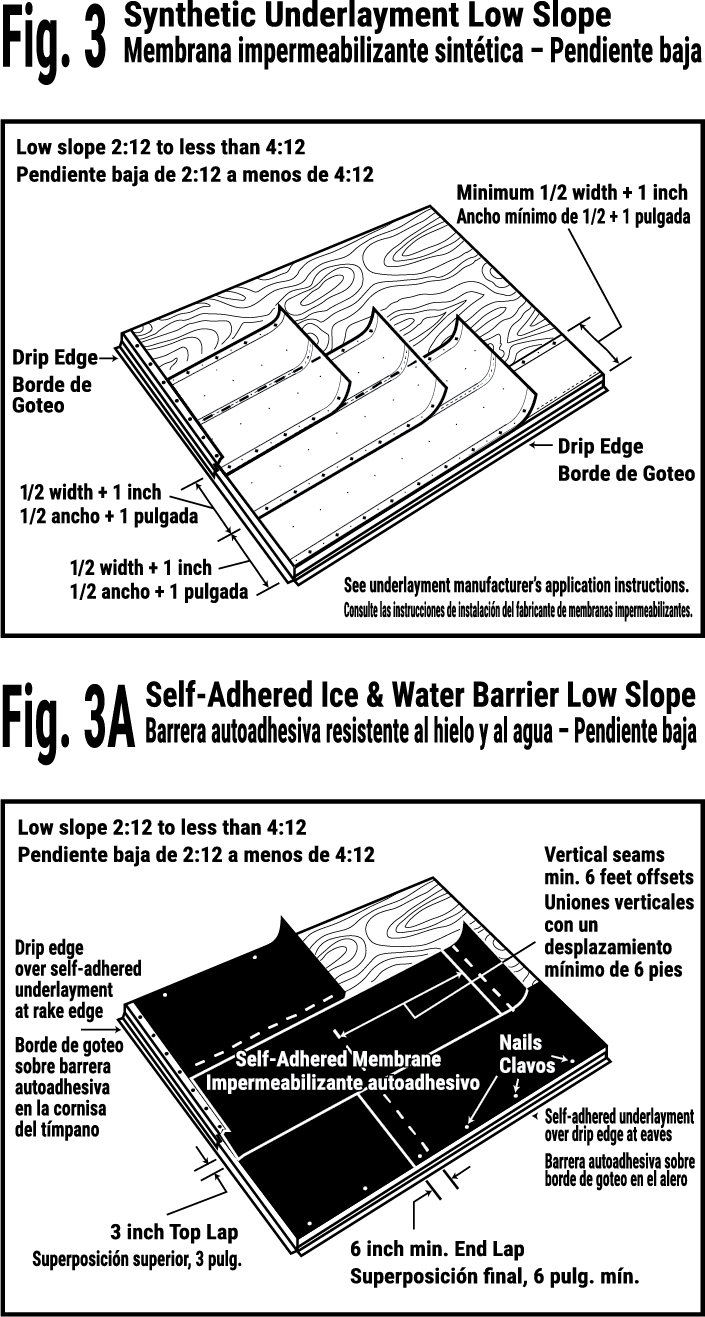

- Before installing this product, check local building codes for roofing requirements.

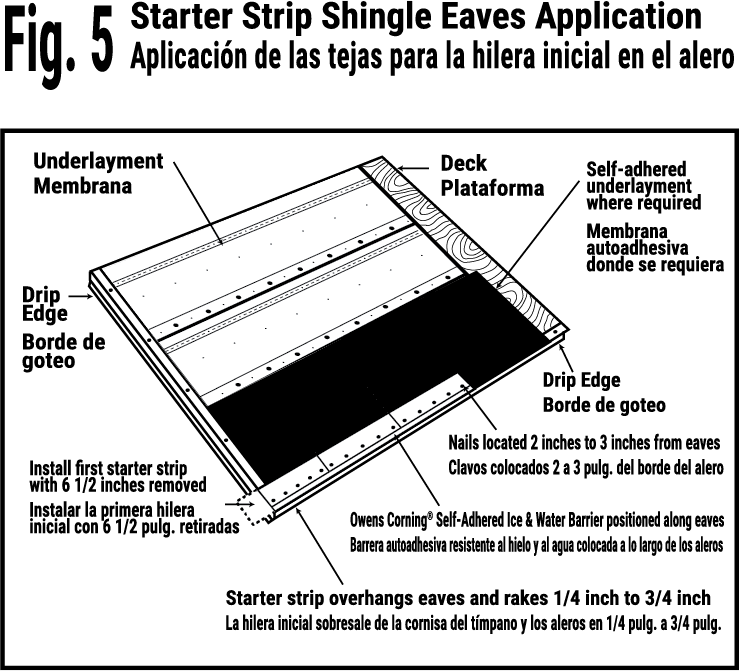

- These shingles are designed for new or reroofing work over any properly built and supported wood roof deck having adequate nail holding capacity and a smooth surface. Must comply with local building codes.

Precautionary Note:

The manufacturer will not be responsible for problems resulting from any deviation from the application instructions and the following precautions:

- Roof Top Loading: Lay shingle bundles flat. Do not bend over the ridge.

- Cold Weather Installation (Below 40F): All field shingles must be installed with an approximate 1/16 inch – 1/8 inch gap on all end/butt joints.

This ensures that any expansion of the shingles which may occur in warmer weather will not cause the shingles to buckle against one another.

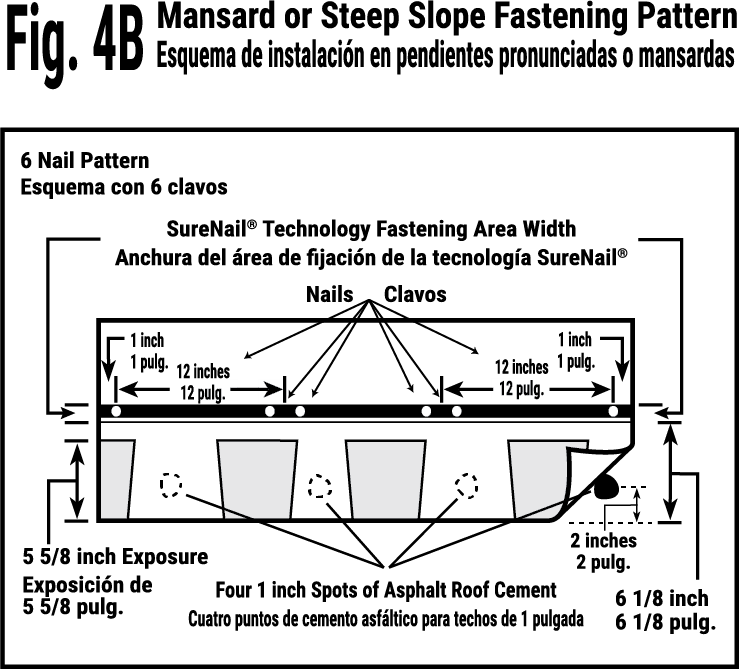

All shingles installed on the perimeter of the roof must be hand-sealed with four 1 inch dabs of ASTM D4586-compliant asphalt cement. See Fig. 4B

This protects against wind uplift which may occur when the temperature is too low for the adhesive strip of the shingles to activate - Roof Deck: Minimum 6 inch roof deck boards, minimum 3/8 inch plywood, minimum 7/16 inch OSB, sheathing spaced minimum 1/8 inch and maximum 1/4 inch. Regardless of deck type used, the roofing installer must:

- Install the deck material in strict compliance with the deck manufacturer’s instructions.

- Prevent the wood deck from getting wet before, during and after installation.

- Ventilation: Must comply with local building codes.

- Handling: Use extra care in handling shingles when the temperature is below 40°F.

- Storage: Store in a covered, ventilated area at a maximum temperature of 110°F. Bundles should be stacked flat. Do not store near steam pipes, radiators, etc.

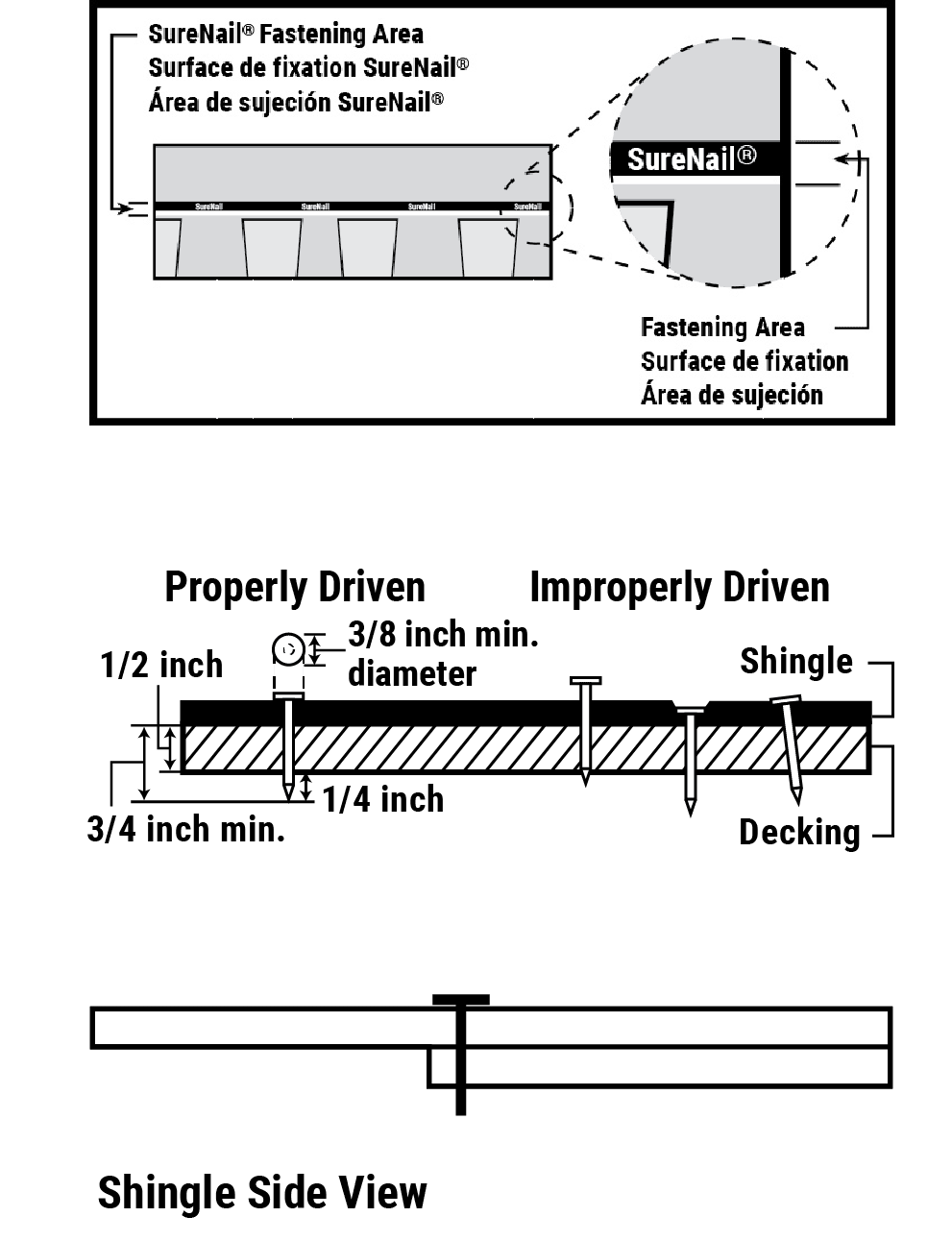

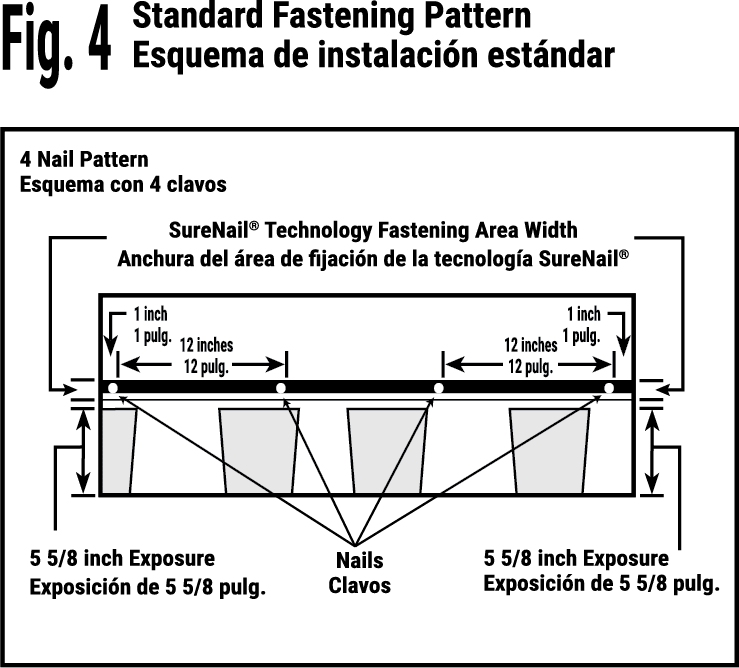

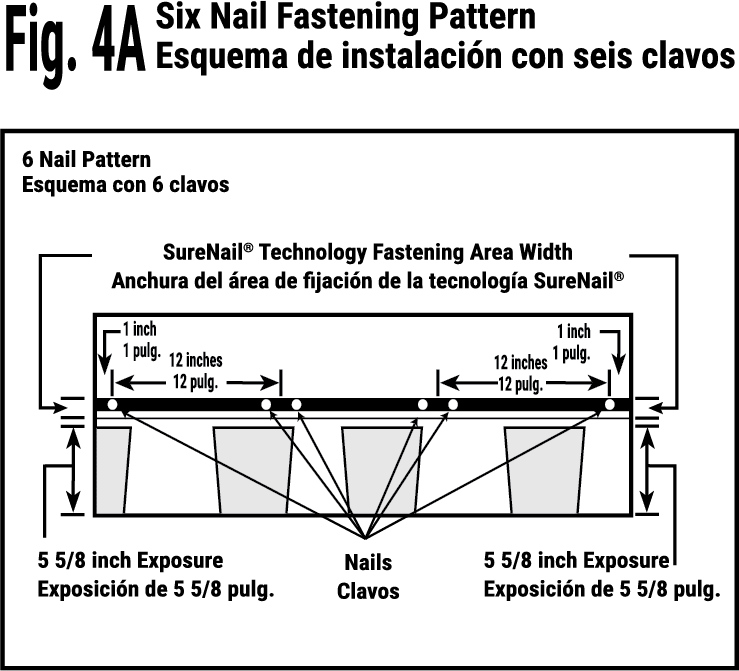

- Fastener Requirement: Use galvanized steel, stainless steel or aluminum nails minimum 12 gauge shank with 3/8 inch diameter head. Owens Corning Roofing recommends that fasteners comply with ASTM F1667. Must comply with local building codes. All fasteners must penetrate at least 3/4 inch into the wood deck or completely through the deck by a minimum of 1/4 inch.

Notice: Owens Corning Roofing requires the use of nails as the method of attaching shingles to wood decking.