- Fire

- Commercial

- Blog

Thermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Blog in Brief

When it comes to achievements, reaching 90 years of service is a milestone to commemorate. A 90-year anniversary is also a good time to reflect, take stock and think about the future. As 2024 marks the 90th anniversary of Thermafiber® mineral wool, I find myself reflecting on why a “workhorse” insulating material renowned for its fire-resistant properties continues to be such a critical component in buildings around the globe – and how it continues to support life safety in new construction.

Always on the Job

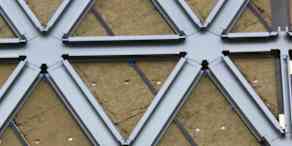

When speaking with architects, contractors and fire professionals, I often use the term “workhorse” to describe how Thermafiber® mineral wool contributes to passive fire protection systems. Passive fire protection systems help extend time for occupants to egress a building. Fire testing demonstrates that mineral wool insulation is a vital component in the passive fire containment system that is designed to withstand direct fire impingement and temperatures exceeding 1,800 ºF. Properly installed in a passive fire protection system, Thermafiber® mineral wool insulation is designed to stay in place, impeding both smoke and fire spread without requiring any activation mechanism.

Pioneering Innovation and Establishing a Legacy of Trust

Experience is a great teacher, and 90 years of fire testing has made the Thermafiber® team industry experts on mineral wool insulation product and system innovation as well as responding to emerging building design trends. Research and development testing combined with “in-the-field” experience have led to a vast repository of engineering judgments that includes a breadth of perimeter fire containment systems installed in varied settings. The Thermafiber® Insolutions® technical consulting team specializes in providing free, customized perimeter fire containment solutions, consultations, engineering judgments and technical expertise to fit the unique requirements of modern commercial buildings.

The art and science of building design is always evolving, and there is no room to rest on yesterday’s laurels. One trend Thermafiber® mineral wool has responded to is the increased use of vision glass. More vision glass in today’s buildings is leading to shorter spandrels. Understanding that design and safety are not mutually exclusive, in 2023 the team developed the Thermafiber® Impasse® Zero Spandrel Perimeter Fire Containment System that offers up to three hours of perimeter fire containment while requiring as little as 0 inches of spandrel height and requires 9 inches of insulation.

Ninety years of longevity in the market also helps build trust. That’s one reason why Thermafiber® mineral wool is installed in some of the world’s tallest buildings. Additionally, Thermafiber® mineral wool insulation is the first insulation designated with the U.S. Department of Homeland Security’s SAFETY Act. The designation provides limited liability to builders and architects using selected products if a terrorist attack occurs.

Contributing to Formaldehyde-Free Building Standards

When Thermafiber® mineral wool insulation was introduced to the market in 1934, the industry gave little thought to environmental sustainability in building and construction. Times have changed and as interest in environmental sustainability continues, so do Thermafiber®’s efforts to deliver products that support customers’ formaldehyde-free building aspirations. Introducing North America’s first formaldehyde-free mineral wool insulation offering, Thermafiber® mineral wool brought a significant advancement to fire protection technology that aligns with the market’s growing demand for formaldehyde-free construction solutions.

Beyond Fire

Ninety years in the industry has allowed Thermafiber® mineral wool to demonstrate material performance in several applications that go beyond fire resistance. For example, special manufacturing processes allow our continuous insulation mineral wool products the ability to provide compression resistant properties that allow for various direct attachments for exterior claddings. Manufacturing technology advances have also contributed to a Thermafiber® mineral wool continuous insulation portfolio of products with the ability to repel moisture and resist vapor infiltration as part of a rainscreen application. In addition, while installed in various applications, Thermafiber® mineral wool products also help manage sound and mitigate noise.

Collaborating and Advocating

Thermafiber® mineral wool has a long history of collaborating with code-setting bodies, testing agencies and industry coalitions that advocate for fire safety. Leadership on industry committees, contributing to industry education through journal publications and speaking at fire safety conferences are part of Thermafiber®’s commitment to educate the fire safety community.

Here’s to the Next 90 Years

With 90 years of service in the rearview mirror, Thermafiber® mineral wool continues to build on its legacy of leadership in advancing mineral wool insulation innovation and fire safety. While no one can predict the future, the spirit of pioneering new innovations to support life safety and high-performing buildings continues to drive Thermafiber®’s solutions for the future. Happy anniversary to Thermafiber® mineral wool, a workhorse in the industry.

©Owens Corning 2024. All rights reserved.

Related Articles

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Jump to a Solution Suite

Jump to a Solution Suite