System

Technical Consulting TeamThermafiber Insolutions®

Need a modification? Want a project-specific drawing? Reach out to our Thermafiber Insolutions®

team to request an Engineering Judgment.

Steel Backpan Interior Side. Aluminum framed curtain wall with glass/aluminum/stone spandrel panels. Min. 6" Sill Height. Min. 30" Spandrel panel. Thermafiber® 3" Firespan® 90 and Safing insulation. STI Sealant.

Assembly Details

F Rating | 2 Hr. |

T Rating | 112 Min. |

Integrity Rating | 2 Hr. |

insulation Rating | 112 Min. |

Linear Opening Width | 4 in Max. |

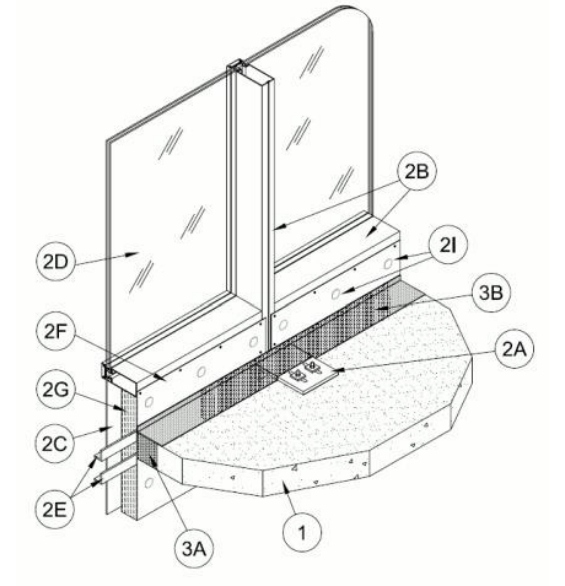

1. Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf) (1600-2400 kg/m3 ) structural concrete.

2. The curtain wall assembly shall incorporate the following construction features:

A. Mullion Mounting Brackets — Min 8 in. (203 mm) wide by 3/8 in. (9.5 mm) thick extruded aluminum Halfen mounting brackets with one nom 4 in. (102 mm) high leg for support and attachment of mullion and with one leg at least 4 in. (102 mm) longer than width of linear opening between floor assembly and mullion. Mounting bracket attached to top of floor with two min 2 in. (50 mm) long by 1/2 in. (12.7 mm) diameter steel masonry wedge anchors in conjunction with washer plates supplied with mounting bracket. Halfen anchors interface with with 3 in. (76 mm) by 2 in. (50 mm) angles, 4 in. (102 mm) long which are installed on inside face of vertical curtain wall mullions oriented with 3 in. (76 mm) leg of angle attached to vertical mullion and 2 in. (50 mm) leg interfacing with steel backpan. Angles secured to vertical curtain wall mullions with 3/8 in. (9.5 mm) diameter bolts which penetrate through mullion and angle on opposite side of mullion secured with a nut.

B. Framing — Rectangular tubing mullions (vertical members) and transoms (horizontal members) shall be min 2-1/2 in. (64 mm) wide by 7 1/2 in. (191 mm) deep and shall be formed from min 0.100 in. (2.5 mm) thick aluminum. Mullions spaced max 60 in. (1.52 m) OC and secured to mullion mounting anchors (Item 2A) at each floor level in conjunction with steel angles bolted to the sides of the mullions as described in Item 2A. Steel angles engage with vertical leg of Halfen anchors. Interior face of mullions to be max 4 in. (102 mm) from edge of floor assembly. Transoms which form the spandrel shall be min 30 in. (762 mm) OC. The maximum height from the top of the floor to the bottom of the horizontal transom is 6 in. (152 mm).

C. Spandrel Panels — The following types of spandrel panels are acceptable:

a. Glass Panels — Nom 1/4 in. (6.4 mm) thick opaque heat-strengthened or tempered glass. Each panel secured in position with aluminum pressure plates in conjunction with glazing gaskets and steel screws.

b. Aluminum Panels — Nom 1/8 in. (3.2 mm) thick aluminum panels with 1/4 in. (6.4 mm) thick edges. Each panel secured in position with aluminum pressure plates in conjunction with gaskets and steel screws.

c. Stone Panels — Nom 1-3/16 in. (30.2 mm) thick polished granite spandrel panels with 1 in. (25 mm) thick gauged edges. Each panel secured in position with aluminum pressure plates in conjunction with gaskets and steel screws.

D. Vision Panels — Nom 1 in. (25.4 mm) thick (double pane) transparent heatstrengthened or tempered glass. Each panel secured in position with aluminum pressure plates in conjunction with glazing gaskets and steel screws.

E. Steel Channels — Nom 1-1/2 in. (38 mm) by 1-1/2 (38 mm) in. deep No. 16 gauge (0.064 in. or 1.6 mm thick) steel angles. Steel channels secured to steel back pans (Item 2F) with No. 10 by 7/8 in. (22 mm) long self-drilling, self-tapping steel screws spaced 8 in. (203 mm) OC. Steel angles located with horizontal leg at 2 in. (50 mm) below the top of slab and 6 in. (152 mm) below the top of the slab, respectively.

F. Steel Backpan — Min 20 gauge (0.036 in. or 0.9 mm thick) galvanized steel backpan attached to interior face of curtain wall framing (Item 2B) with No. 10 by 7/8 in. (22 mm) long self-drilling, self-tapping steel screws spaced max 8 in. (203 mm) OC. Back pans engage with curtain wall framing by minimum 1 in. (25 mm) on all edges.

G. Curtain Wall insulation* — Nom 3 in. (76 mm) thick mineral wool batt insulation faced on one side with aluminum foil/scrim vapor retarder. Unfaced mineral wool batt insulation is also acceptable. insulation batts to be installed with no vertical or horizontal seams, and are tightly-fitted between vertical mullions and the transoms, flush with the interior surface of framing. Score curtain wall insulation panels so that the L-angle stems fit into the score of the insulation, allowing curtain wall insulation panels to fit tightly up against the steel back pan. insulation panels secured to steel backpan with cup head weld pins (Item 2I) spaced max 12 in. (304 mm) OC both vertically and horizontally, with perimeter weld pins spaced maximum 2 in. (50 mm) from edge of each curtain wall framing member. Cup head weld pins are minimum 12 ga, 3 in. (76 mm) long, with length to match the thickness of the curtain wall insulation, and have a minimum 1-3/16 in. (30.2 mm) diameter head washer. THERMAFIBER INC — Firespan 90

H. Framing Covers - Curtain Wall insulation* — (Not Shown) — Min 8 in. (203 mm) wide strips cut from min 2 in. (50 mm) thick mineral wool batt insulation faced on one side with aluminum foil/scrim vapor retarder. Framing covers to be centered over mullions and shall extend from bottom surface of safing system (Item 3A) to spandrel sill transom. Framing covers to be secured to the spandrel framing members with self-tapping, min. No. 10 machine screws spaced maximum 12 in. (304 mm) on center with min. 1-1/2 in. (38 mm) diameter steel washers.

I. Weld Pin — Nom 3 in. (76 mm) long No. 12 gauge galvanized steel weld pin with nom 1-3/16 in. (30.2 mm) diameter galvanized steel cup head used to secure curtain wall insulation. Cup head weld pins inserted through curtain wall insulation and welded to steel backpan (Item 3F).

3. Max separation between edge of floor assembly and face of framing member at time of installation is 4 in. (102 mm). The safing system is designed to accommodate vertical shear up to 5 percent of its installed width. The safing system shall incorporate the following construction features:

A. Forming Material* — Nom 4 pcf (64 kg/m3 ) density mineral wool batt insulation. Batt sections cut to a 4 in. (102 mm) width and stacked to a thickness which is min 25 percent greater than the width of the linear gap between the curtain wall insulation and the edge of the concrete floor slab. The forming material is compressed and inserted cut-edge-first into linear gap such that its top surface is flush with the top surface of the floor assembly. A max of one tightly-butted seam is permitted between mullions. Additional piece of forming material to be friction-fit into gap between batt sections above mullion mounting clip at each mullion location. THERMAFIBER INC — SAF

B. Fill, Void or Cavity Material* — Min 1/8 in. (3.2 mm) wet thickness (1/16 in. or 1.6 mm dry thickness) of fill material spray-applied over top of forming material and lapping min 1/2 in. (12.7 mm) onto the top surface of the floor and onto the steel back pan (Item 2F) and framing covers (Item 2H).

SPECIFIED TECHNOLOGIES INC — SpecSeal AS200 Elastomeric Spray, SpecSeal Safing Spray or SpecSeal Fast Tack Spray

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada), respectively