Thermal insulation tank base solutions for tanks operating at cold temperatures

Thermal insulation tank base solutions for tanks operating at cold temperatures

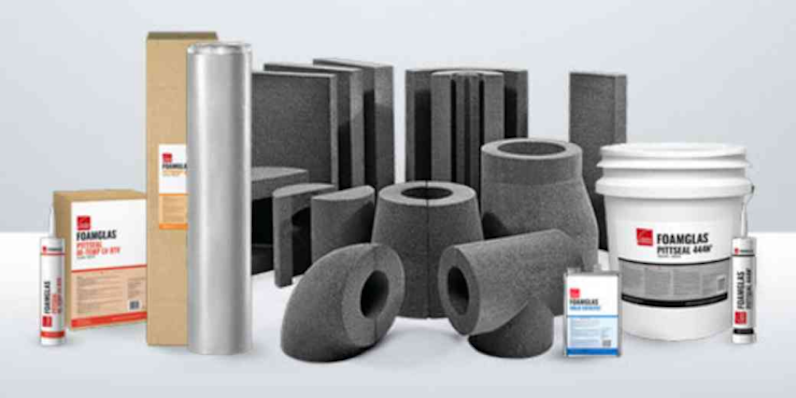

Since the 1960's, tank builders worldwide have trusted FOAMGLAS® insulation as a core component in tank base insulation systems. Today, thousands of tanks are supported by FOAMGLAS® insulation systems.

In an application for a low temperature tank base, lack of compressive strength can result in an unacceptable settlement which may result in a loss of thermal insulating capacity, ground heaving and foundations being brought to temperatures that could result in major failures. In the case of uneven subsidence, rupture in the tank’s steel bottom could result in a subsequent loss of product.

A dedicated tank base insulation under your low temperature tank can help avoid excessive heat transfer, which could cause the support structure to freeze and create mechanical problems. It can also help protect the structural material against extreme temperatures. This requirement is important with liquefied gases, which are stored at such low temperatures that normal containment products can become brittle in direct contact.