- Moisture

- Industrial

- Blog

Considerations for insulating district energy systems

Blog in Brief

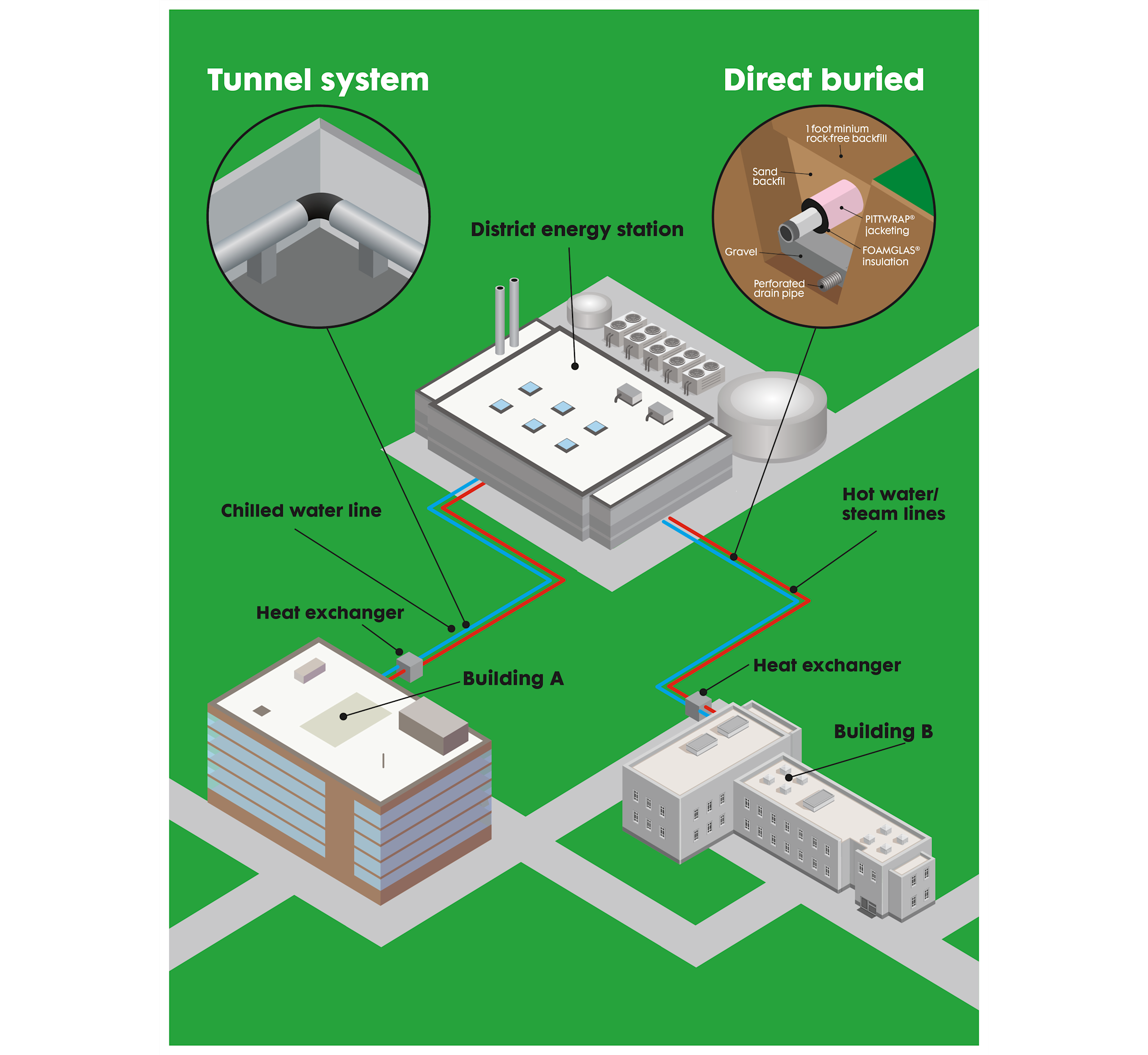

District energy systems are an increasingly popular way to provide temperature regulation efficiently to multiple buildings in an area, for example, on a university campus or medical complexes. The systems typically employ a dedicated district energy station that provides heating and cooling to multiple buildings using chilled water and hot water or steam lines. Often the piping involved is underground either direct buried or in vaults and tunnels. Both situations bring a range of challenges to consider when designing the insulation for the pipes involved. A well-designed insulation system should provide sufficient process control to heating and cooling processes, reduce overall energy expenditure and maximize the lifespan of the system. Careful design considerations including accounting for compressive strength, dimensional stability, thermal regulation and moisture. Using an insulating material like FOAMGLAS® cellular glass insulation can help address these design considerations and help ensure efficient long-term system function.

Considerations for insulating district energy systems

As more companies and municipalities look at ways to reduce energy expenditure, conversations around using district energy systems are increasing. District energy systems can be used to provide energy-efficient heating and cooling to a range of multi-facility sites such as airports, universities, medical complexes and cities or municipalities. The systems are intended for long-term use, and some in service today were initially installed in the late-19th and early 20th centuries.

The integrated systems use a dedicated location to provide heating and cooling to nearby buildings through a network of chilled water, hot water or steam line pipes. These pipelines are often underground and are either direct buried or located in tunnels and vaults. To ensure that the system continues to function efficiently and effectively, known challenges need to be considered during the design phase to ensure pipes are adequately protected. Repairs to underground systems can be a lengthy and expensive process. In extreme cases, the need to excavate underground pipes for repair or replacement can costs as much as $50,000 per foot, as pipes may be buried 10.5 to 12 meters (about 35-40 feet) below the surface.

Moisture Intrusion

Insulation systems on district energy piping will have different challenges to overcome depending on the location and conditions of the system. However, one concern almost always present is the issue of moisture intrusion into the system. It has been estimated that moisture is related to about 98% of all insulation failures.1

If water can penetrate and take the place of air within an insulation material, it can greatly reduce the insulation’s thermal efficiency. This is because water is a much better conductor of heat than air. This reduction in thermal efficiency can lead to a loss in process control, including a reduction in cooling/heating effect delivered to inhabited buildings. It can also lead to increased energy and even maintenance costs for the system, as process equipment must work harder to return hot/cold process lines to their intended temperatures.

Corrosion under insulation (CUI) is a less obvious form of damage that can occur when moisture penetrates pipe insulation. When left unchecked, corrosion under insulation can develop undetected for years, or even decades, until a catastrophic failure of the system is realized. The primary objective for the prevention of CUI should be the prevention of moisture ingress into an insulation system. When moisture penetrates a permeable insulation, it can collect against the outer edge of the chilled water pipe and act as an electrolyte for electrochemical processes, such as corrosion, to take place. By preventing moisture from penetrating an insulation system, a key ingredient for corrosion can be prevented.

Risks for chilled water lines

Chilled water lines typically operate from around 2°C (36°F) to 13°C (55°F). The fact that these pipes typically operate below ambient conditions of the environment brings specific challenges when it comes to moisture intrusion.

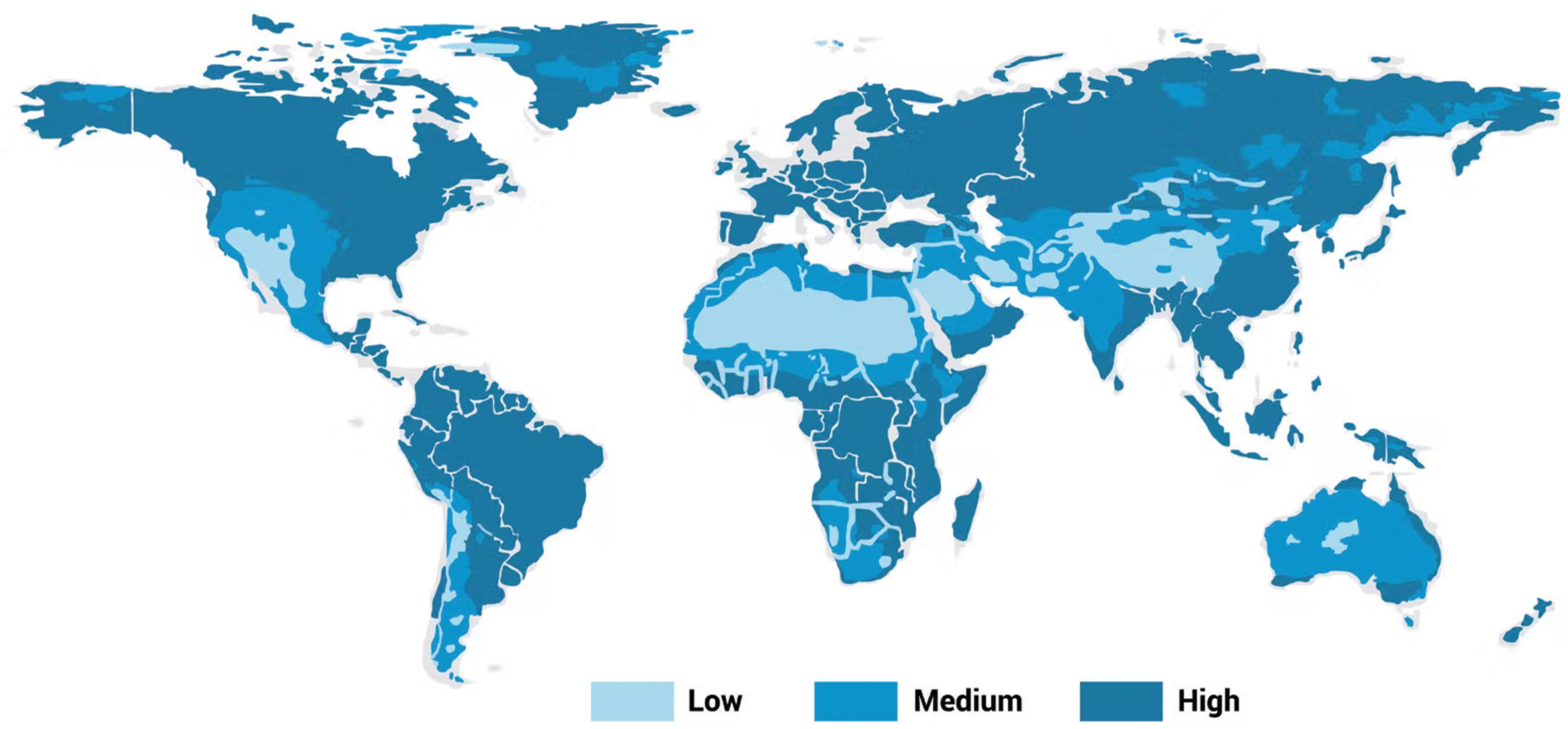

Warm air has a greater capacity to hold moisture as vapor than cold air. Relative humidity is a percentage ratio that describes the relationship between total moisture concentration of a given airspace to the actual amount of moisture it can hold at a given temperature. At 100% relative humidity, air is considered saturated and has no more capacity to hold additional water as vapor. Humidity varies regionally, making It important to know the conditions of the specific location where the system will be installed.

As ambient air encounters cold surfaces, it cools down. Since cold air has a lower capacity to hold moisture than warm air, this increases the relative humidity of the air local to the cold surface. This can continue until 100% relative humidity (saturation) is reached, at which point any additional cooling will result in the air losing moisture via condensation. This temperature where air, when cooled to it, will begin losing moisture via condensation is called the “dew point.”

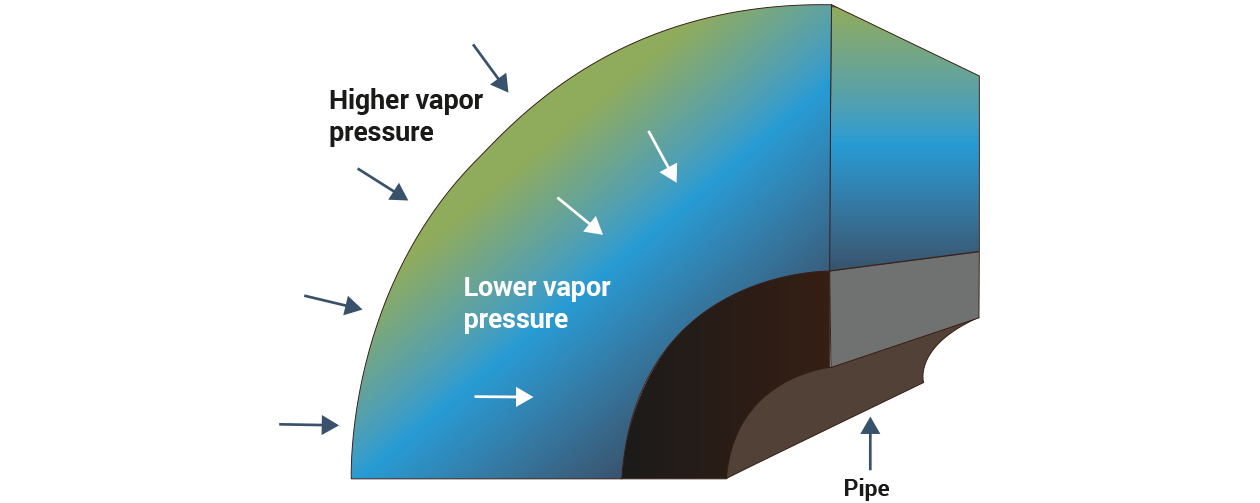

“Vapor pressure” is defined as the force exerted by a vapor that is in equilibrium with its condensed phase at a given temperature. Vapor pressure can be viewed as the tendency of a liquid to transition into its gaseous form in a closed system and increase with temperature. In general, this means that warm areas of high vapor pressure will tend to drive moisture towards cooler airspaces of low vapor pressure. This tendency of vapor in the air to move from warm to cold areas is commonly referred to as “vapor drive.” The combination of this vapor drive, along with the presence of cold surfaces below an airspace’s dew point, makes condensation a concern when it comes to chilled water pipes.

When designing an insulation system, one element to consider is the permeability of the insulation to be used. Permeability relates to how willing a material is to allow liquids or gases to pass through it. When using permeable insulation, an external vapor barrier is needed to prevent water from entering the system. If the barrier is damaged, it can allow moisture and water vapor to penetrate the insulation. Activities that can impede vapor barrier function include incorrect installation practices, physical damage, rough maintenance practices and daily traffic.

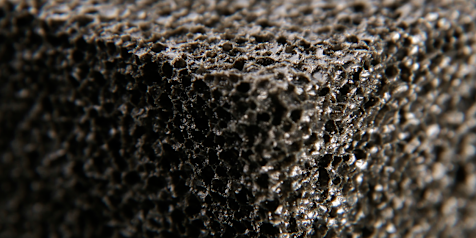

However, not all insulation is permeable. Closed-cell materials tend to have much lower permeability than materials that are open-cell or granular in nature. A low- or zero-permeability insulation will better protect against water vapor traveling into the insulation, which will help maintain its thermal performance.

Direct buried considerations

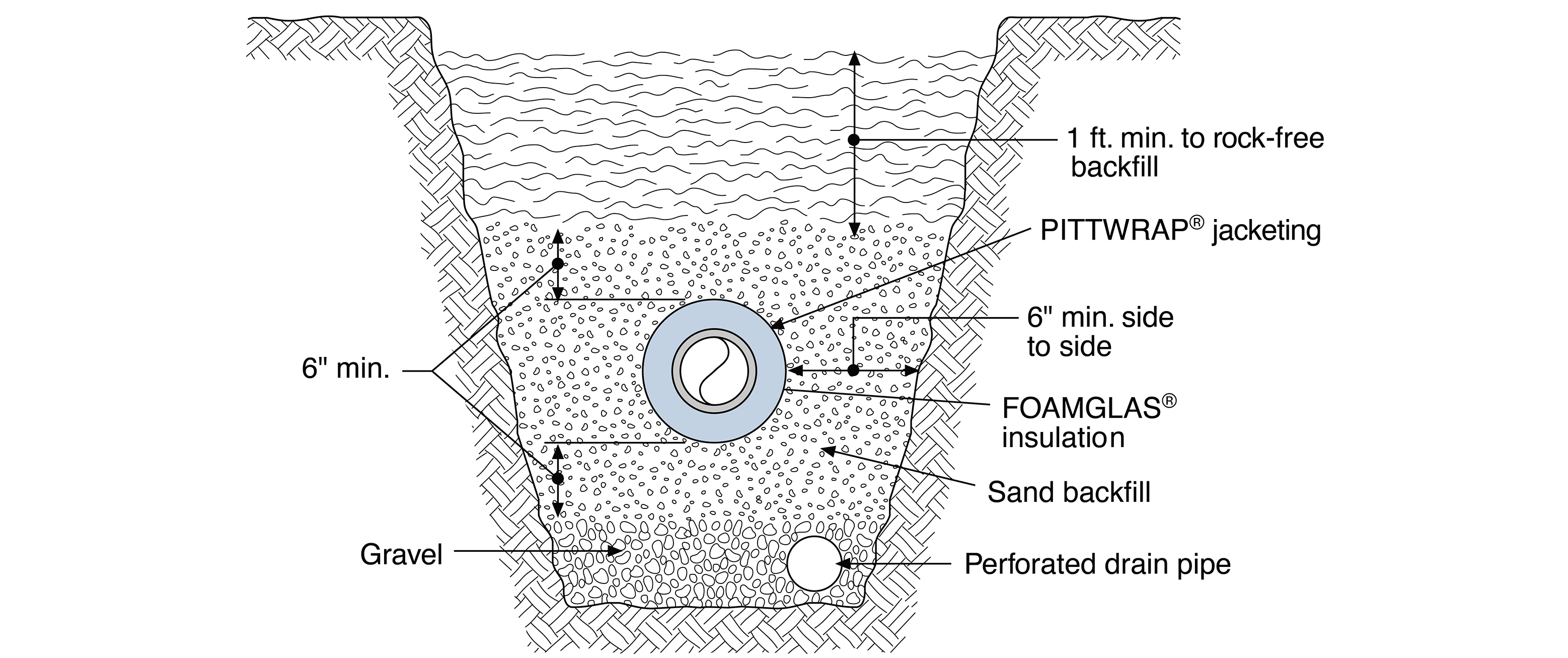

A cost-effective way to run pipes for district water systems is to bury them underground. However, there are some challenges that must be considered with hot or cold pipes in these situations. These include accounting for the weight placed on top of pipes, hydrostatic pressure, the presence of moisture and high-water tables and the potential for system movement.

Weight, pressure and stability

Additional factors that must be considered when designing insulation for pipes that will be direct buried include the dimensional stability and compressive strength of the insulation. Buried pipes experience several types of loading, and the insulation used needs to be strong enough to maintain its structure and thermal performance while in service.

Buried pipes carry the direct load of the backfill located on top of the pipe. This increases the further down the pipe is buried and the more backfill is compressed. Pipes also bear live load, which is weight applied above ground. This can be static, like when pipes run under a building, or live, as when pipes run under a walking path or road.

Additionally, hydrostatic pressure can force moisture into contact with insulation used to protect pipes. Hydrostatic pressure is pressure exerted by moisture in the ground. If a permeable insulation is used and the jacketing or vapor barrier gets damaged, this can force moisture into the insulation. Along with a damaged moisture barrier, hydrostatic pressure can be a concern for sealed areas, including joints or protrusions in insulation. Hydrostatic pressure also can increase in areas with high water tables or when soil is saturated. Use of an impermeable, nonabsorbent insulation with a high compressive strength and dimensional stability can help mitigate these risks.

System movement and heat transfer

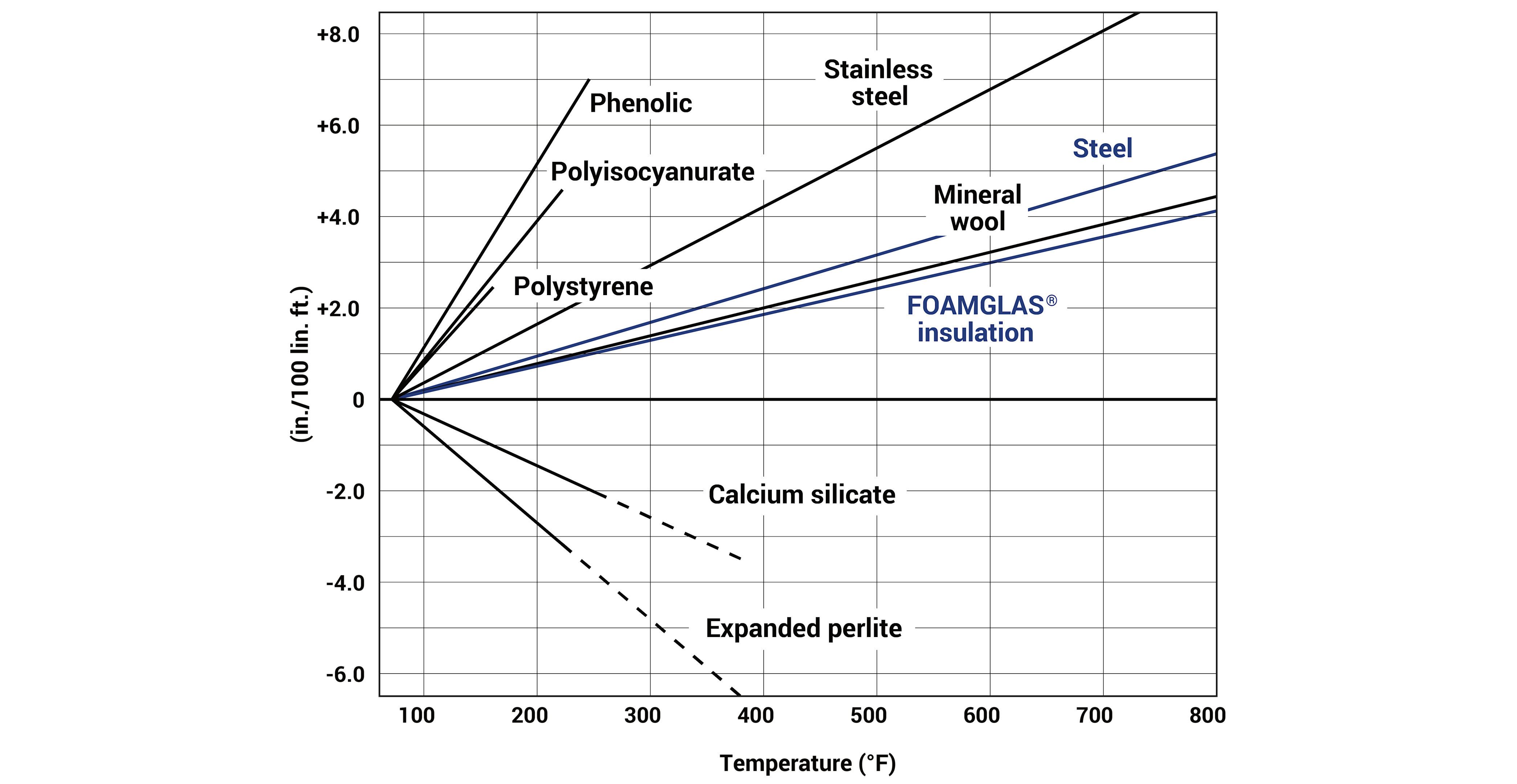

Insulation designs for high-temperature pipes, like steam or hot water lines, need to account for pipe movement. As pipes heat up, they expand, and that movement must be addressed in scenarios where the system is buried in soil. Expansion loops and zees should be designed into piping systems where needed, and considerations should be made to the insulation used. Using an insulation with a thermal expansion and contraction similar to the material used in the pipe can help ensure the insulation system will withstand the movement it will be subjected to.

Since soil is a poor insulating material, if the insulation on hot pipes is damaged, heat can leach away from hot lines and move toward chilled water pipes, prompting a loss of efficiency in both systems. Heat loss into soil also can damage other utility lines, like electrical wiring near the hot pipes, especially if they are encased in PVC piping or have a meltable exterior.

Vault and tunnel considerations

In some locations it is more common to house district energy system pipes in tunnels and vaults rather than burying them. This is more likely to happen in areas where constant levels of high water in the soil would make burial difficult, and in cold locations where it would be hard to locate pipes under the frost line. Like direct buried pipes, pipes in vaults and tunnels also face risks that must be addressed when designing the insulation system.

Flooding

A common risk for pipes in tunnels and vaults is flooding. Pipes can be briefly submerged in floodwater or experience being dripped on from overhead. If moisture can penetrate permeable insulation, it can decrease the thermal efficiency of the insulation and increase the potential for other damage to occur, including corrosion. Using a robust insulation system with a moisture barrier and closed-cell insulation that will not absorb moisture can help prevent moisture from finding a way to reach the pipes.

Local heat transfer

When pipes are in tunnels, steam or hot water lines tend to be near chilled water lines, with only air to act as a barrier. Other types of utilities also may run through the same space, including fiber optic cables, computer network cables and powerlines. If the insulating system on the high-temperature pipes is incorrectly installed or damaged, it can cause a rapid increase in heat in the tunnel, which could damage other utility lines. It also could introduce heat into nearby chilled water lines, making the system less efficient and straining chiller cooling the system.

Accidental damage and vermin

Depending on the size of the space where pipes are located, which can range from a crawlspace to walkways, there can be traffic in the tunnels. It is not uncommon for insulation systems to be damaged by foot traffic when maintenance activities are taking place in tight spaces. Any insulation system installed needs to be robust enough to protect itself from incidental damage. Additionally, using an inorganic insulating material can help deter vermin from eating or nesting in the insulation.

District energy insulation system checklist

When selecting the insulation and accessories used to protect the longevity and efficient function of district energy system pipelines, there are several important factors to address. Insulation used should provide constant thermal performance and be impermeable to moisture, resisting both water and water vapor. The insulation will need to have long-term dimensional stability that is similar to the material of the pipe it is protecting, and it will need to have a high compressive strength, especially if used in a direct buried application. It also may be important to select insulation that is noncombustible, resistant to corrosion and inorganic to deter burrowing vermin. Insulation selected should be paired with appropriate accessories like jacketing and sealants that are intended for use with that material in underground/direct buried applications.

FOAMGLAS® cellular glass insulation is an example of a suitable material for environments like this. The closed-cell, cellular glass material is lightweight, rigid and has a high compressive strength. It provides consistent thermal performance across a wide temperature range and has a coefficient of thermal expansion close to that of steel, allowing it to accommodate the movement in hot pipes.

Importantly, cellular glass insulation is nonabsorbent, non-wicking and impermeable to water and water vapor. Because it will not absorb moisture, it also does not warp or swell. Additionally, the inorganic material is noncombustible and resistant to rodents, insects and mold growth. A series of accessories has been designed for use with FOAMGLAS® insulation, including jacketing materials such as PITTWRAP® HS jacketing, PITTWRAP® SS jacketing and PITTWRAP® CW Plus jacketing.

Conclusion

There are a series of considerations that must be made when selecting the materials to insulate underground piping and when designing the insulating system for pipes used with district energy systems. Some of the planning questions to ask during system design include:

- How much load or pressure will be exerted on the system?

- What will happen when the trench or tunnel is flooded?

- What risks could be caused by tunnel traffic?

- What extreme weather events are likely to happen and can the insulation mitigate them?

- What will happen to the system if an abrupt stop in operations occurs?

- What is the expected service life of the system? Has the insulation been designed to support that?

Although there are many factors that an insulating system needs to cover to protect district energy lines, it is possible to design insulation that provides the needed support. Selecting a close-celled, impermeable insulation that does not absorb moisture, warp or swell and that is impermeable to vapor and has a high compressive strength and dimensional stability, like FOAMGLAS® cellular glass insulation, can help address many of the challenges pipes face.

References

- Adams, L. (1974). Thermal Conductivity of Wet Insulations. ASHRAE Journal, 61–62.

- Kehrer et al. (2002). Cremaschi, Cai, Ghajar et al. (2012). Jerman and Cerny (2012).

- A.M. Gusyachkin et al. (2019). IOP Conf. Ser.: Mater. Sci. Eng. 570012029.

© 2022 Owens Corning. All rights reserved.

Related Articles

Related Articles

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Jump to a Solution Suite

Jump to a Solution Suite