- Thermal

- Industrial

- Blog

KEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Blog in Brief

Placing piping underground has been a widely accepted way of designing and installing process piping networks for decades. Underground piping networks are used to distribute chilled water, hot water and steam, or to transport gas or other fuels. Installing piping networks underground offers advantages such as space-saving design, improved employee safety, reduced risk for mechanical damage and an additional barrier from the elements. However, unless these piping networks are designed and installed properly, the underground system can potentially face many hazards.

Direct Burial Applications

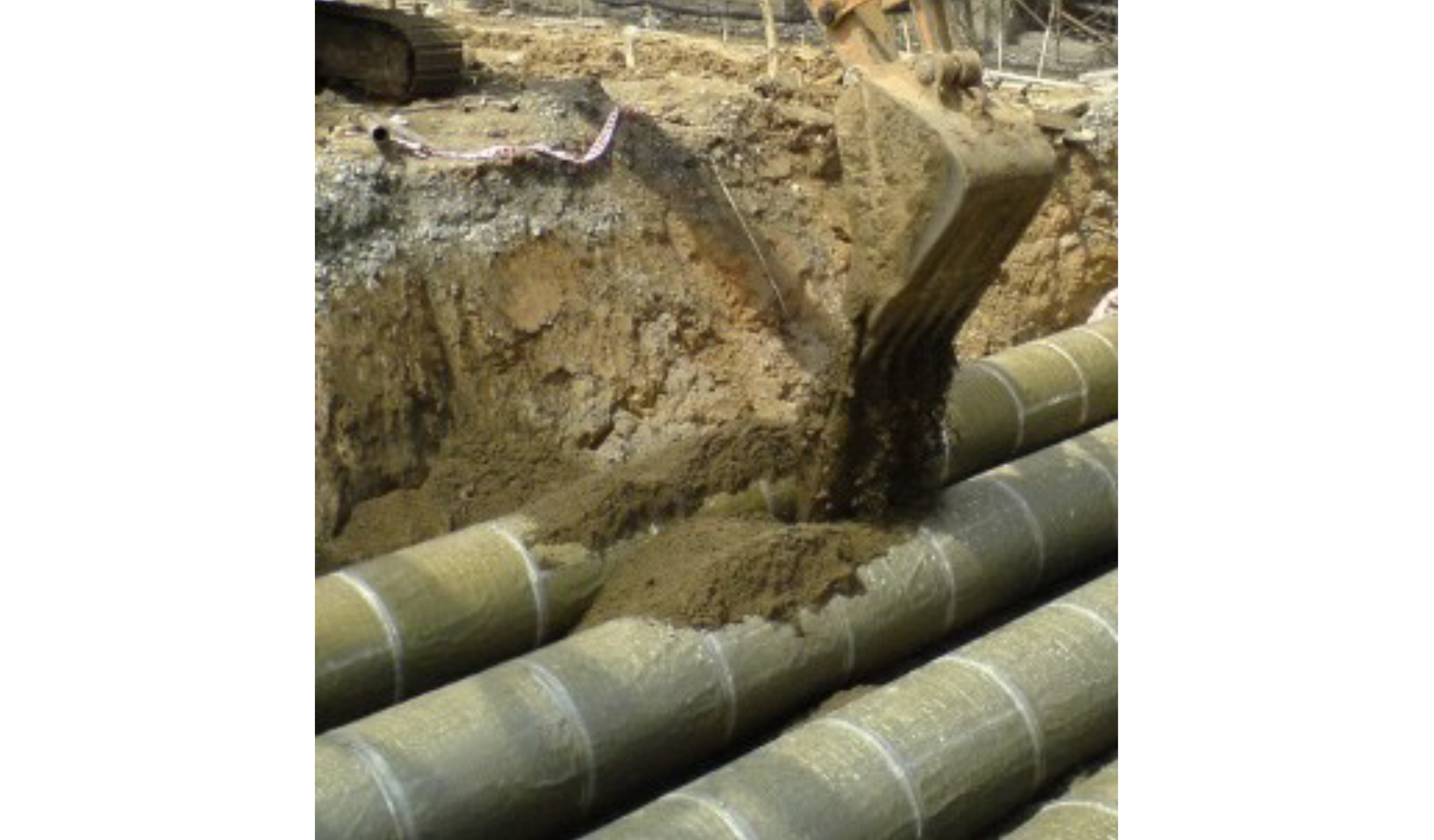

The direct burial of insulated pipelines is often the most practical method of installing underground piping systems. This method eliminates the need for costly tunnels and speeds the installation of the piping system. Buried pipelines and their insulation systems are required to withstand internal hydrostatic pressure as well as soil load, traffic and other external loads. It’s not just the piping network that must be designed to withstand these loads, it’s also critical that insulation systems be designed for these service conditions.

The ideal insulation system should meet the mechanical requirements of being buried while also providing long-term insulation efficiency and protection against moisture intrusion, which could lead to corrosion-related issues. Ignoring these basic considerations may result in problems.

Design Considerations

The success of a direct burial system depends upon the system chosen, proper design and proper installation. Some of the key considerations that should be addressed by the design professionals prior to selecting an insulation system include:

- Type of system: chilled water, hot water, steam or other

- Operating temperatures of all pipes (hot, cold, constant or cycling)

- Pipe length, diameter, burial depth, number and nature of runouts

- Soil type, bearing strength, electrical potential

- Location of water table

- Control of expansion/contraction

- Other conditions, such as traffic loads, depth below road, etc.

Thermal Requirements For Direct Burial Insulation Systems

Although it is possible to use direct burial systems for low-temperature liquid transport, it is rarely done due to the problems associated with potential freezing and heaving of the ground, especially in the presence of water. Underground chilled water networks are used in district cooling systems but are almost never used citywide. The low temperature difference makes district cooling distribution costly, so networks are typically built in areas with high cooling demand densities, such as downtowns and commercial areas. The majority of direct burial applications are for above ambient piping, such as hot water and steam. Thermal requirements for these applications include limiting the heat transfer for economic reasons, limiting the temperature variations of the fluid between the beginning and the end of the line for process reasons, and limiting coating temperature to an acceptable value.

Considerations Regarding Heat Transfer Calculations

When calculating the acceptable heat transfer, it is important to consider the influence of the ground’s thermal conductivity in the calculation of heat transfer and that of the insulation’s outside surface (or coating) temperature. This can be physically explained by the fact that the pipe is insulated by the insulation material and the ground around it.

This means that low ground thermal conductivity will increase the insulation surface temperature on an above ambient system and reduce the heat transfer, while high ground thermal conductivity will decrease the insulation surface temperature and increase the heat transfer on that system.

The ground’s thermal conductivity varies with its moisture content, which is higher during a wet period than during a dry period. Moreover, the value can be difficult to accurately measure, particularly when considering a long pipeline going through various zones. Consequently, many specialists calculate the insulation’s outside surface temperature with a relatively low thermal conductivity of the ground and the heat transfer with relatively high thermal conductivity of the ground.

Mechanical Strength

Providing adequate mechanical strength of insulation is key. Direct buried installation systems must sustain high loads, coming from both the static pressure applied by the soil around a pipe as well as from traffic loads and other overburden loads. Therefore, insulation materials with a high compressive strength, and without the need for additional structural protection, are preferred for direct burial applications. This will help ensure that the insulation does not compress and harm the thermal efficiency and overall performance of the system.

All pipes expand and contract in direct proportion to a temperature change. It is crucial that the expansion and contraction of pipework are addressed at the design stage of a project to avoid significant problems.

The expansion of the pipe can usually be accommodated by installing expansion loops or expansion joints. Proper insulation of underground expansion loops or mechanical devices is a requirement for design, installation and, ultimately, the successful operation of an underground system.

Protection From Moisture And Its Consequences

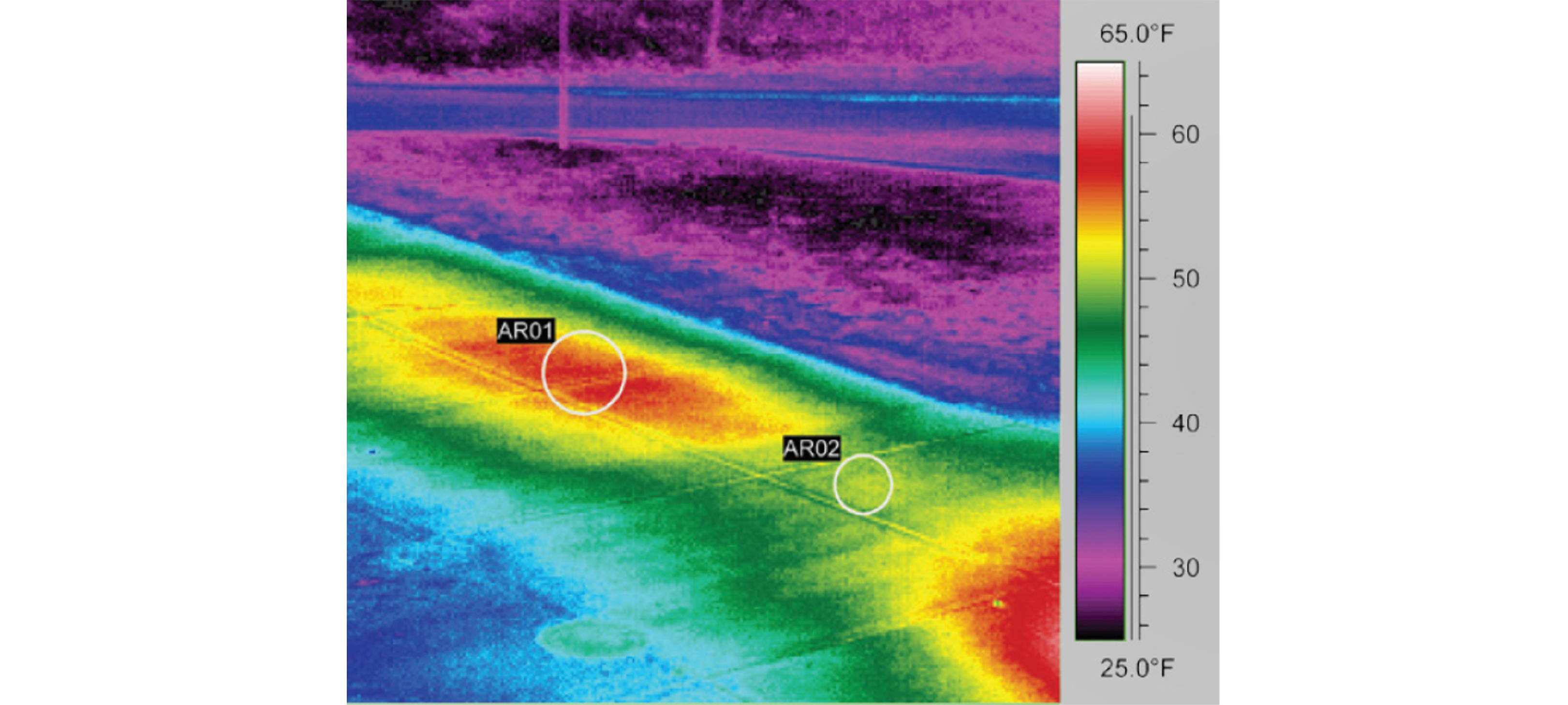

Underground piping systems should be protected with an insulation system that can meet the moisture and corrosion resistance requirements of direct burial in order to provide long-term insulation efficiency. Water intrusion into underground piping systems, particularly in areas with high water tables, may lead to major increases in the effective thermal conductivity of the wet thermal insulation. This can greatly reduce the effectiveness of the insulation system while also creating an environment for other consequences, such as corrosion.

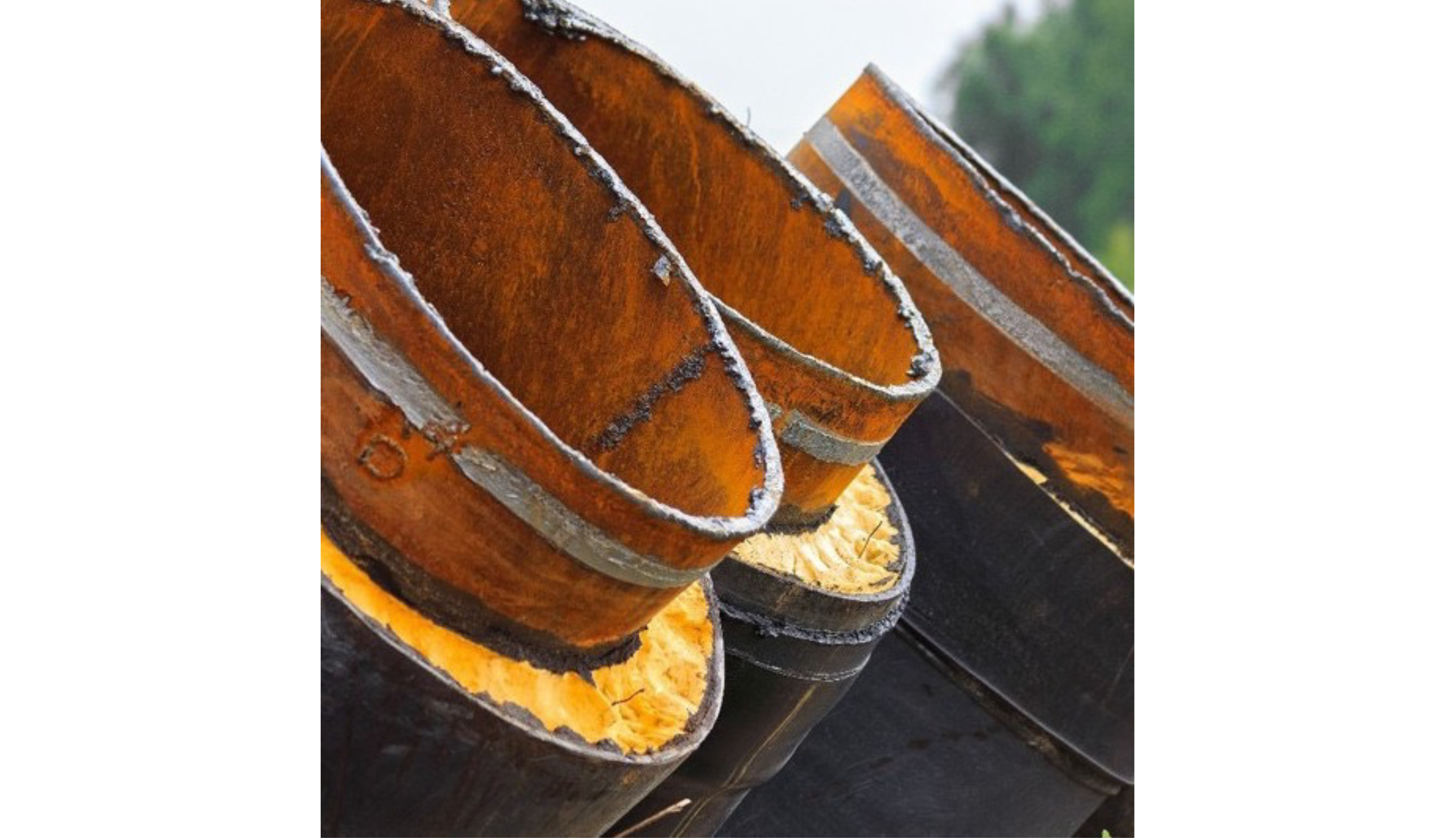

Many of these pipes are made of steel and, therefore, could be subjected to the formation of corrosion when exposed to moisture. Corrosion of piping networks can affect the integrity of the system and could eventually lead to a total failure of the system.

For this reason, it is often preferred to protect direct burial piping systems with an impermeable insulation material that assists with keeping the system dry and maintaining its integrity over time.

The Benefits of FOAMGLAS® Cellular Glass Insulation

In most underground applications, it is vital that the temperature is kept constant over the entire length of the underground piping network to help safeguard process control. A FOAMGLAS® insulation system helps to ensure that the temperature inside the pipes is controlled and kept stable by limiting the heat transfer to the cold soil.

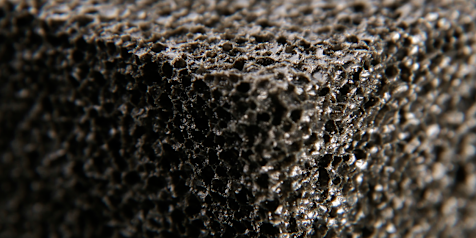

When a pipe is buried directly into the ground, it must withstand a high amount of compression, while also being subjected to moisture penetration. FOAMGLAS® insulation has a high compressive strength, enabling it to withstand pressure from the surrounding soil as well as pressure from other overburden loads.

FOAMGLAS® is an inorganic, closed-cell material that can retain its strength while being impermeable to moisture. This means that, by using a FOAMGLAS® insulation system, one can help limit the risk of moisture penetration to the system and mitigate corrosion on the piping network. This will help to ensure long-term thermal performance and keep operating costs in check.

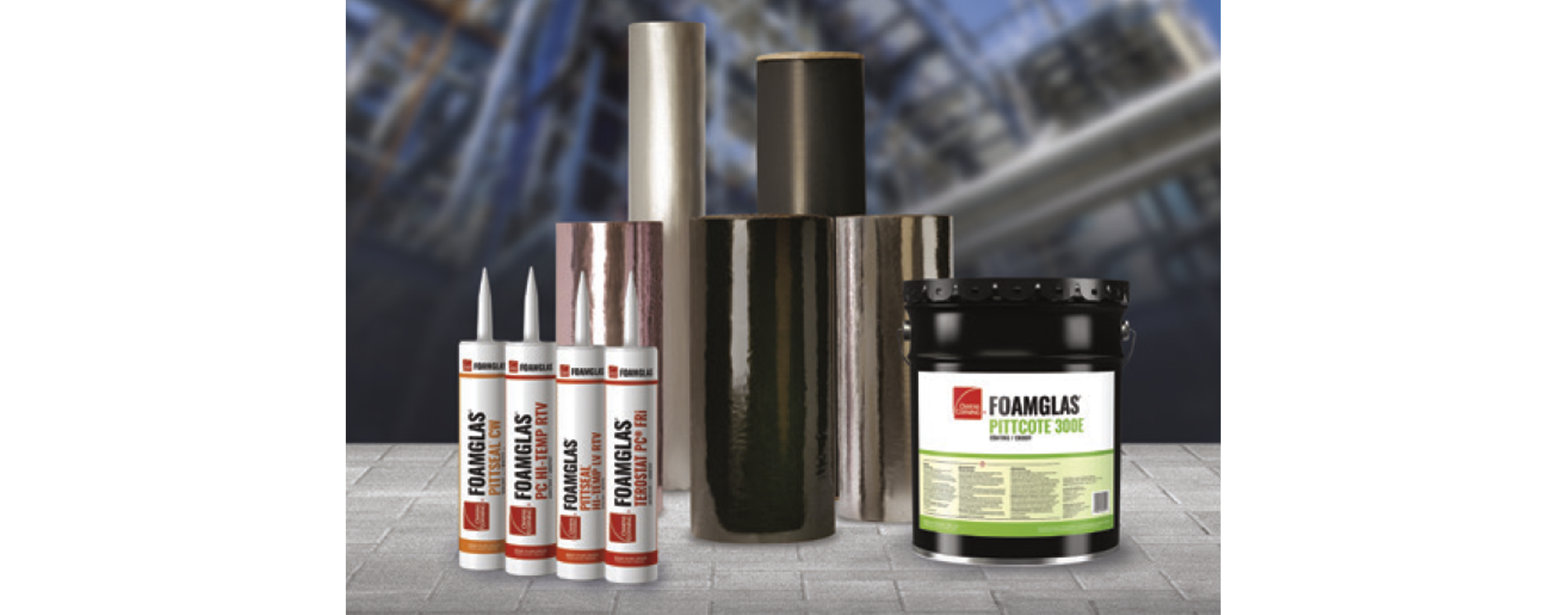

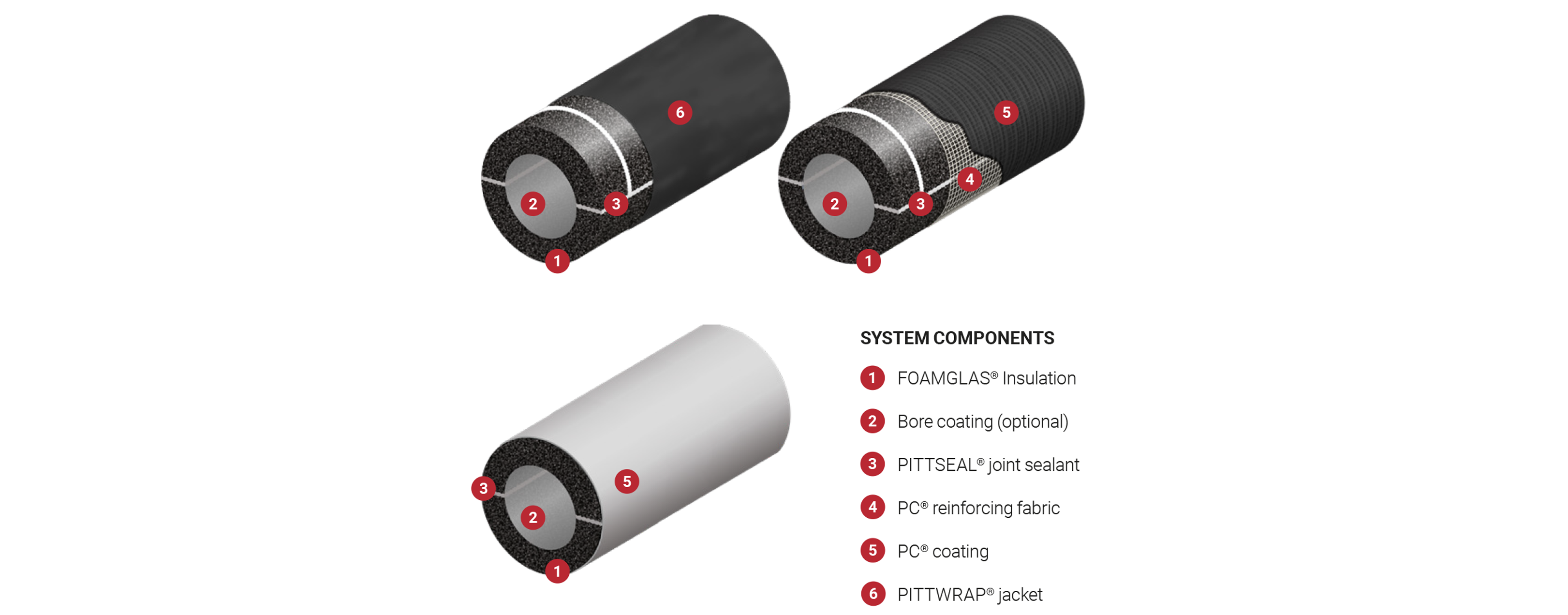

Dedicated FOAMGLAS® Insulation Systems

To achieve a high-quality, long-lasting insulation system, we recommend a total system approach when specifying insulation systems for direct burial applications. This includes a high-compressive strength, closed-cell, impermeable insulation along with jacketing, sealants and more that are designed specifically to work with the insulation to create a waterproof system. Our recommended accessories consist of a wide array of coatings, jackets, adhesives and sealants that have been formulated, designed and tested for proven performance in combination with FOAMGLAS® insulation for a large number of applications.

A typical FOAMGLAS® insulation system for direct burial application consists of a layer of FOAMGLAS® ONE™ cellular glass insulation in combination with a flexible PITTWRAP® vapor barrier or a PC® coating, possibly in combination with a PC® glass fabric reinforcement. Joints can be sealed with one of our dedicated PITTSEAL® sealants or silicone adhesives in line with the system’s operating temperature.

On hot, buried systems located in high water table areas, improperly sealed systems may allow moisture to enter. Our PITTWRAP® HS jacketing and PC® coating solutions provide a resilient, waterproof membrane against most soil and water conditions in direct burial applications. All PITTWRAP® jacketing grades may be factory-applied on FOAMGLAS® insulation, and some self-sealing PITTWRAP® jackets are modified bituminous membranes that can be applied manually without a torch or heater. Our PC® coatings can be used to achieve a vapor retarder layer on irregular surfaces where jacketing may be difficult to apply.

Three unique jacketing options form the basis for direct buried FOAMGLAS® insulation systems that are appropriate for different applications.

- PITTWRAP® HS (Heat Seal) jacketing is recommended for protecting FOAMGLAS® insulation used on buried systems with outer surface temperatures ≤ 190°F (88°C).

- PITTWRAP® SS jacketing, a self-sealing jacketing, is recommended for protecting FOAMGLAS® insulation used on buried systems with outer surface temperatures ≤ 170°F (77°C).

- PITTWRAP® CW Plus jacketing is a self-sealing jacketing designed for use over FOAMGLAS® insulation applied to direct buried chilled water and hot water systems.

Conclusion

Direct burial is a practical method of installing underground piping systems. Its success depends on informed design that takes into account the type of system, operating temperature, surrounding soil and other considerations. Specifying an insulation system that includes impermeable insulation with a high compressive strength along with integrated accessories that create a waterproof membrane can help ensure a stable, sealed direct piping system.

Related Articles

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite