- Moisture

- Mechanical

- Blog

Five mechanical insulation considerations for healthcare facilities

Blog in Brief

There are multiple elements to evaluate when selecting the insulation to be installed on a specific project. Often, the considerations need to account for challenges — like moisture pressure or pipe temperature — that the insulation will encounter. When selecting the insulation to use on piping in facilities with additional requirements, like hospitals or healthcare centers, there are performance attributes that must be addressed, including hygienic performance, ease of use and resistance to mold or mildew development. Insulation like our SSL II® with ASJ Max Fiberglas™ Pipe Insulation can meet these additional performance metrics and help ensure the optimal function of the building’s mechanical systems.

Five mechanical insulation considerations for healthcare facilities

Technical advances, innovative designs and psychological awareness have sparked changes to hospital design in recent years. While some of these changes — like additional natural lighting and the installation of greenspace and vegetative roofs — are quickly evident, others, like mechanical system design changes, are harder to see. However, there has been an increasing awareness of the role that insulation plays in protecting the performance of mechanical systems in these facilities. Our recent work with an expansion project for a hospital based in Rapid City, South Dakota, helped explicate some of the performance attributes that should be sought during the insulation selection process. Five performance attributes were considered during the selection process, including moisture resistance, polymer jacketing, insulation thickness, fastening and ease of use.

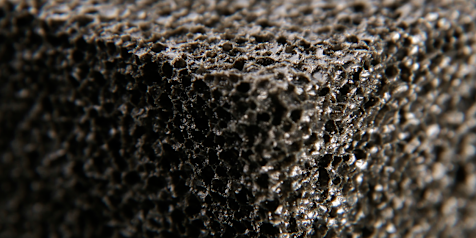

Moisture resistance

The need for insulation piping in healthcare facilities to be moisture resistant goes beyond wanting to protect thermal function. Insulating materials used in healthcare facilities must resist moisture infiltration to help protect against dangerous mold and mildew growth. Using an insulation like our SSL II® with ASJ Max Fiberglas™ means that the insulation would have a moisture-resistant polymer exterior jacket, which helps promote the highest level of safety. The jacketed insulation system does not support mold growth as tested in accordance with ASTM C1338 – Standard Test Method for Determining Fungi Resistance of Insulation Materials and Facings. According to the Center for Disease Control, the presence of mold can generate a range of health issues, from stuffy noses to skin rashes, and immune-compromised individuals can develop lung infections when mold is present.1

Polymer jacketing

Jacketing material is important for more than just moisture resistance when insulation is applied in a healthcare facility. The outer surface of the insulation needs to be smooth, long-lasting, wrinkle-resistant and cleanable. When using an insulation with a polymer surface jacketing, the material can be cleaned as needed to remove dust and dirt – an important consideration in a location where hygiene is critical. As insulation may be added early in a renovation or expansion project, creating time for dirt or particulate matter to adhere during the rest of the construction work, so being easy to clean allows that debris to be removed following project completion. Another reason to keep insulation clean is that dirt provides food for mold. About 45 million buildings in the U.S. have problems with mold growth and mold-related infections are estimated to cost the economy about $5.6 billion annually.2,3

Variety of insulation thickness

The piping and mechanical systems in a hospital can be complicated, as they could feature a range of differently sized pipes, at different temperatures, needing different thickness of insulation. Insulation selected needs to be able to accommodate multiple requirements. At the Rapid City facility, for example, cold water piping needed ½-inch thick insulation, while chilling pipes needed 1.5 inch of insulation thickness and the hot water pipes needed insulation that was 1 inch thick. Our SSL II® with ASJ Max Fiberglas™ Pipe Insulation could support these needs, as it’s available in a range of thicknesses. Insufficiently thick insulation is less effective, which reduces a facility’s energy efficiency. This can be quite relevant for healthcare facilities, as they are one of the top two most intensive users of energy in the commercial sector, according to the U.S. Energy Information Administration.4

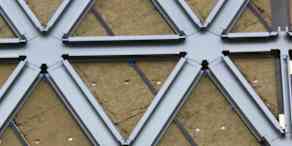

Secure fastening

Insulation also needs to remain securely in place after it has been installed to prevent the need for rework and reduce risk of moisture penetration. With a double adhesion fastening, insulation with the SSL II® system seals securely and does not need additional glues, mastics or staples to ensure closure. Once sealed, the binding is firm and continues to harden for the next 24 hours. Running a hospital or healthcare facility is energy intensive, meaning that insulating materials need to work correctly. Gaped or opened insulation is less effective, but correctly installed and sealed mechanical insulation is estimated to save a medical facility 149 kBts/sf a year or about 78% of the site’s total energy use.5

Ease of use and installation

The mechanical systems in a healthcare facility can be complex and vast – meaning a large amount of insulation may be needed before the project is completed. The easier the insulation is to use, the less time and frustration will be spent on insulation. At the Rapid City project, there were times that 15 team members were installing insulation, making ease of use an important consideration for the insulation selected. Our insulation also has a flex core option, which is able to reduce, if not eliminate, the need to fillet insulation to fit around smallbore copper pipes and fittings. Using the flex core insulation can save up to 16% of labor hours on an insulation project.6

Conclusion

When selecting insulation for use in buildings with specific needs, there are a range of performance attributes that should be considered. Thinking through the project and selecting insulating materials that best fit the project’s needs can improve the process and reduce frustrations while helping to ensure optimal performance of mechanical systems.

Here is more information on projects and products available to support work on healthcare facilities. And here is more information on the installation and use of SSL II® with ASJ Max Fiberglas™ Pipe Insulation.

Related Articles

Related Articles

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Jump to a Solution Suite

Jump to a Solution Suite