System

Technical Consulting TeamThermafiber Insolutions®

Need a modification? Want a project-specific drawing? Reach out to our Thermafiber Insolutions®

team to request an Engineering Judgment.

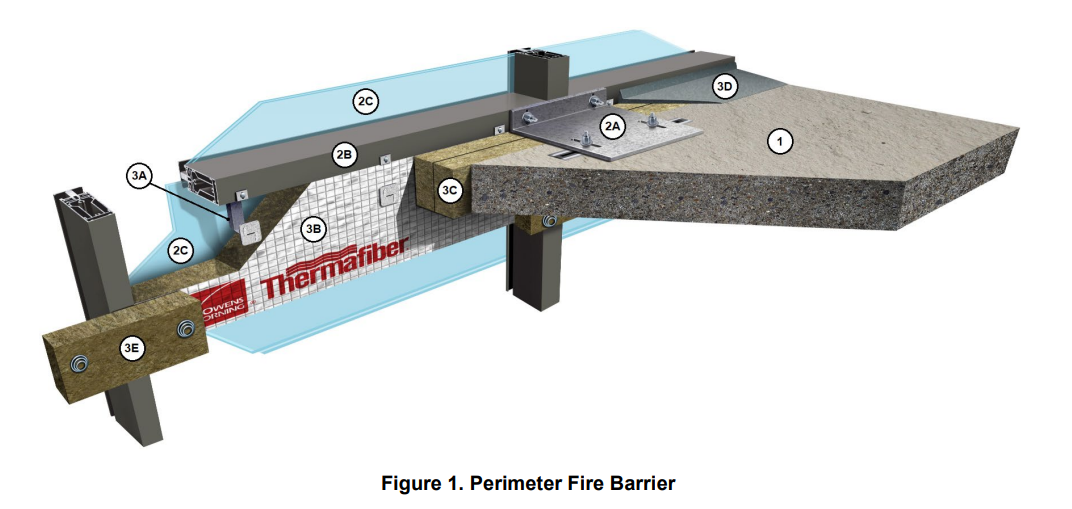

Zero Spandrel System. No valance. Aluminum shadow box can be incorporated. Thermafiber Impasse 2.0, Firespan 120, and Safing Insulation. 9" Spandrel height with 0" to 3" sill height. 2-Hr. F Rating. All Intertek E2307 certified Smoke Sealants.

Assembly Details

F Rating | 2 Hr. |

T Rating | 56 Mins. |

1. CONCRETE FLOOR ASSEMBLY: Min. 2 hour rated concrete floor assembly made from either lightweight or normal weight concrete with a density of 100-150 pcf, with a min. thickness of 6 in. at the joint face. When a longitudinal recess (blockout) is required to contain an architectural joint system, increase concrete floor assembly thickness to maintain a minimum thickness of 6 in. and accommodate the depth of the blockout formed in the concrete. The blockout width is unrestricted.

2. CURTAIN WALL ASSEMBLY: Incorporate the following features:

A. MOUNTING ATTACHMENT - Attach the vertical aluminum framing members (mullions) to the structural framing or to the top side of the concrete floor assembly according to the curtain wall manufacturer's instructions. Max. distance between anchored mullions is 60 in.

B. ALUMINUM FRAMING - Size rectangular aluminum tubing mullions and transoms according to the curtain wall system manufacturer's guidelines. Min. overall dimensions of framing required is 0.145 in. thick aluminum, with a min. 4 in. depth and a min. width of 2-1/2 in. for horizontal members and vertical members. Overall depth of framing system including mullion and transom covers shall be min. 5 in. Mullions are to be spaced with a max. of 60 in. between mullions. The spandrel transoms are to be positioned to have 9 in. of space between the top and bottom transom. The lower face of the top spandrel transom is to be located 0 in. to 3 in. above the top surface of the concrete floor assembly (Item 1).

C. GLASS PANELS AND SPANDREL PANELS - Size and install glass panels to curtain wall framing according to the curtain wall system manufacturer's guidelines. Use a minimum of 1/4 in. thick, tempered glass.

3. PERIMETER JOINT PROTECTION: The perimeter joint (linear opening) is not to exceed 4 in. wide (joint width at installation) as measured from the interior face of the curtain wall assembly aluminum framing (Item 2B) and the face of the concrete floor assembly (Item 1). Incorporate the following construction features:

A. INSULATION HANGER - Owens Corning™ Thermafiber® Impasse 2.0* Horizontal Hangers, spaced maximum 6 in. from vertical mullions and 12 in. on center (oc) elsewhere. Use the hangers to install the spandrel insulation (Item 3B) into the spandrel areas framed out by the aluminum framing members. Each hanger is impaled into the spandrel insulation with the forked leg. It is secured with an Impasse® locking washer which is placed over the protruding forks which are then bent in opposite directions.

B. SPANDREL INSULATION - Intertek- Certified, Thermafiber® FireSpan® 120: Install the spandrel insulation tightly fit into the spandrel areas which are framed out by the aluminum framing members (bottom spandrel framing not shown in Figure 1.). The foil-scrim side of the insulation shall be installed facing toward the concrete floor assembly. Use No. 10 or No. 12 self-drilling screws to secure the insulation hangers to the transom (horizontal aluminum framing member) forming the upper part of the spandrel area.

C. PACKING MATERIAL - Intertek-Certified, Thermafiber® Safing: Install minimum 4 in. deep into the joint with the fibers running parallel to the slab edge and curtain wall. Compress the packing material 33% in the joint width. Install flush to the top of the concrete floor assembly or recessed maximum 1/8-in. if installing fill, void, or cavity material (Item 3D).

D. FILL, VOID, OR CAVITY MATERIAL - Apply any Intertek Certified sealant or tape that has been certified as a fill, void, or cavity material for perimeter fire barrier systems certified to ASTM 2307.

E. Intertek-Certified, Thermafiber® Safing: Protect vertical mullions (Item 2B) with minimum 2-1/2-in. thick x 2-in. height x 12- in. wide Thermafiber® Safing installed directly under the perimeter joint protection packing material (Item 3C). Safing attached using 3-1/2-in. long Thermafiber® Spiral Anchors, one on each side, at 30% compression.