- Fire

- Commercial

- Blog

FAQs About Thermafiber® Mineral Wool Insulation

THERMAFIBER® MINERAL WOOL INSULATION PRODUCT BASICS

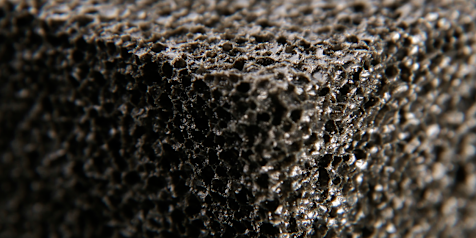

1. What is Thermafiber® mineral wool insulation made from?

Thermafiber® mineral wool is made from a mixture of rock and slag. Slag is a byproduct of steel production. The slag and rock are melted and spun into fibers.

2. Does Thermafiber® mineral wool insulation provide a vapor barrier?

Thermafiber® FireSpan® and VersaBoard® mineral wool insulation products can be purchased with no facing (plain) or with an FSP foil facing applied to the blanket. The FSP foil facing provides a vapor retarder. The FSP foil facing has a 0.02 maximum perm rating.

3. What happens if Thermafiber® mineral wool insulation gets wet?

When the material is wet, the insulating value is reduced. However, if the insulation is allowed to dry and is not mechanically changed in form, the thermal properties will return to their original levels.

4. How much moisture is absorbed by Thermafiber® mineral wool insulation products?

Testing per ASTM C1104 resulted in moisture absorption of less than 1% by volume.

5. Is Thermafiber® mineral wool insulation resistant to mold and fungi growth?

Thermafiber® insulation is an inorganic material. Therefore, it does not provide a food source necessary for mold growth. We have conducted fungi-resistance testing on our Thermafiber® 4.0 and 8.0 pcf density products per ASTM Standard C 1338, which is the test method for determining the resistance of insulation to the growth of fungi. Test results determined the material to have no fungal growth.

6. Can facings be applied to Thermafiber® mineral wool products?

Thermafiber® FireSpan® is available in plain or with a silver foil, vapor-retardant facing. Thermafiber® RainBarrier® Dark™ is available with a factory-applied black fiberglass facing to provide camouflaging behind open-joint façade systems and eliminates need for additional field-installed facing. Thermafiber® VersaBoard® is available in plain or with a white foil, a silver foil, or black fiberglass facing depending on needs of the application.

7. Does Thermafiber® mineral wool have a certification program for installers?

Thermafiber® fire performance products are certified by Underwriters Laboratories (UL®) and Intertek®. However, we do not certify installers or installations. We rely on field inspectors and building code officials to determine that the product(s) were installed correctly and that they meet the intent of the original design.

8. Do the requirements of ASTM C 612 apply to commercial construction?

ASTM C 612 is a standard that applies to thermal insulation in high-temperature applications.

THERMAFIBER® AND PERIMETER FIRE CONTAINMENT

9. Does Thermafiber® mineral wool insulation have an hourly rating? Is Thermafiber® RainBarrier® continuous insulation NFPA 285 approved?

Thermafiber® mineral wool insulation does not have an hourly fire rating as a stand-alone product. The fire rating is for the entire fire containment assembly. The mineral wool insulation is the workhorse of the system but requires mechanical fasteners and other construction components to stay in place for the time period of fire exposure. If these components fail, then the mineral wool insulation will fall out of place, jeopardizing the fire performance of the assembly. For hourly fire ratings on specific assemblies, go to the Underwriters Laboratories Online Fire Resistance Directory or Intertek’s Building Products Directory.

10. Is Thermafiber® RainBarrier® continuous insulation NFPA 285 approved?

NFPA 285 applies to the complete assembly, rather than individual components of the assembly. For this reason, RainBarrier® continuous insulation does not carry NFPA approval on its own. However, RainBarrier® has been tested as an integral part of many NFPA-approved systems.

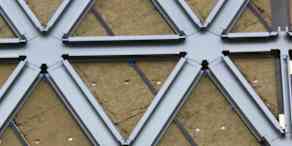

11. What Thermafiber® mineral wool insulation products are acceptable as curtain wall insulation in UL® and/or Intertek® perimeter fire containment systems?

FireSpan® 40, FireSpan® 90, and/or FireSpan® 120 are the only Thermafiber® curtain wall spandrel insulations approved for use in UL® and Intertek® ASTM E2307 tested and listed perimeter fire containment assemblies. Please see specific assemblies for details on which product to use and the hourly fire rating.

12. Can Thermafiber® Safing mineral wool insulation be used with other types of insulation?

Thermafiber® Safing insulation must be used in conjunction with Thermafiber® FireSpan® insulation, to provide fire containment at the perimeter of high-rise buildings by confining the fire to the floor of origin.

13. What if the void between the floor slab and the perimeter curtain wall is a width greater than the recommended 2” to 8”?

The standard safe-off area width Thermafiber® has evaluated through fire tests for dynamic systems is typically up to 6” max. For static conditions, the joint widths were tested up to 8″. For greater gap widths (greater than 8”″), Thermafiber® provides recommended installation methods for protecting wider safe-off openings. Please email us for more information.

14. Can Thermafiber® Safing mineral wool insulation be installed from underneath the slab edge?

In assemblies where Thermafiber® Safing cannot be installed from the top of the slab edge, Thermafiber® Safing insulation can be installed from underneath the slab. Contact the Owens Corning® Thermafiber Insolutions® Technical Consulting Team for installation details.

15. Can Thermafiber® mineral wool products provide fire containment for a precast exterior wall?

Thermafiber® FireSpan® installed to protect the precast panel, with Thermafiber® Safing insulation compression-fit within the safe-off area, can provide fire containment for interior joint between the rated floor assembly and the precast wall.

16. What if I need an engineering judgment for the configuration of Thermafiber® mineral wool in my design?

The Owens Corning® Thermafiber Insolutions® Technical Consulting Team provides knowledgeable, thorough engineering judgments when a configuration doesn’t precisely match those previously tested and rated by UL® and Intertek®. As pioneers in perimeter fire containment, we’re able draw on 25 years of data to produce an engineering judgment you can feel confident in.

17. Are Thermafiber® mineral wool products Factory Mutual (FM) approved?

Thermafiber® products are currently UL® and Intertek® Listed and Approved for use in many fire containment designs. Specific Thermafiber® products carry UL® and Intertek® approved labels. Both FM Approval and UL Approval follow the same process.

THERMAFIBER® SUSTAINABILITY FEATURES

18. Is Thermafiber® mineral wool insulation considered a “green” building product?

Thermafiber® mineral wool insulation products are available with EPA Choice Fiber (up to 75% pre-consumer recycled content) or standard fiber (with a minimum of 70% pre-consumer recycled content). Thermafiber® products also contribute to various green building programs including LEED® and Green Globes®. Select Thermafiber® mineral wool insulation products are available in our formaldehyde-free formulation and are UL® GreenGuard® Gold certified and have Declare® labels.

19. What is the recycled content of Thermafiber® mineral wool bonded products?

Recycled content (pre-consumer)

- Standard fiber mineral wool products: Minimum 70%

- EPA Choice fiber mineral wool product (U.S. govt. projects): 75%

- Available by request, please contact your local ASM.

Recycled content (post-consumer)

- All Thermafiber® products: 0%

20. Is formaldehyde-free Thermafiber® mineral wool available?

Thermafiber® mineral wool is available in formaldehyde-free formulation for the following products: FireSpan®, Safing, SAFB™ and Fire & Sound Guard® Plus.

21. Do Thermafiber® mineral wool products contain chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs)?

Thermafiber® products do not contain CFCs or HCFCs. Nor does the manufacturing of our products produce these ozone-depleting substances.

Conclusion

Thermafiber® mineral wool insulation is designed to deliver exceptional performance in commercial buildings. The Thermafiber® team is here to support your next project with answers to these questions – and any others you may have about specifying Thermafiber® mineral wool. Learn more about Thermafiber® here or email us with additional questions.

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite