WHY CHOOSE FOAM BOARD insulation?

WHY CHOOSE FOAM BOARD insulation?

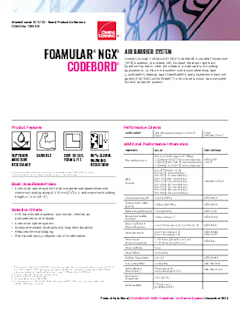

Owens Corning® FOAMULAR® NGX® CodeBord® Air Barrier System (CABS) combines acrylic sheathing tape (JointSealR™), flashing tape (FlashSealR®), and polyethylene foam sill gasket (ProPINK® ComfortSealR™) to form and function as a complete exterior air barrier system.