- Thermal

- Mechanical

- Blog

Labor saving features to reduce pipe insulation installation time

Blog in Brief

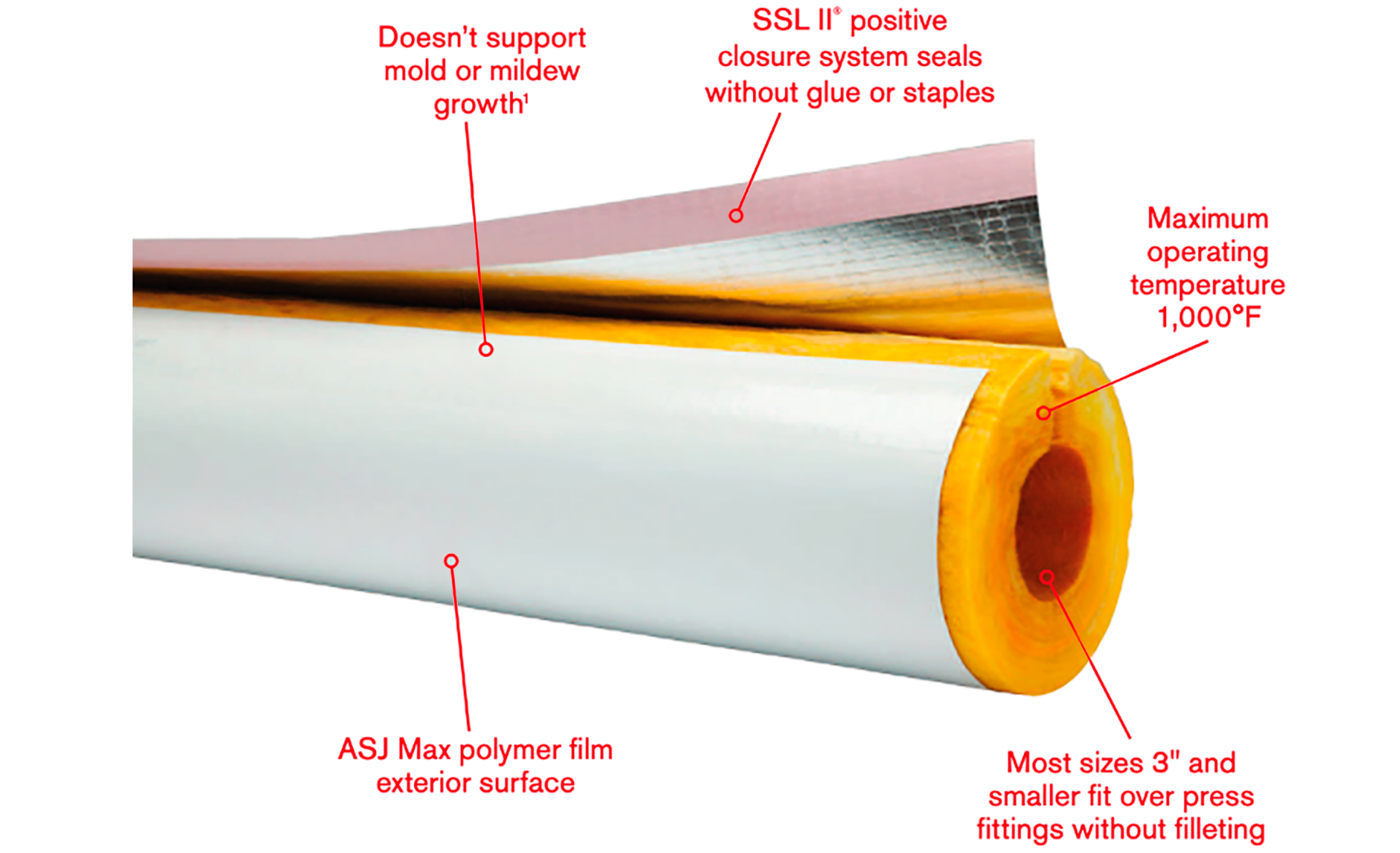

The U.S. construction industry isn’t getting faster and may be slowing down – an element that is playing out globally as the construction sector sees only modest global gains in productivity on an annual basis.1 This finding from a sector study done in 2017 was concerning and prompted us to explore ways to help reduce the time construction projects took and seek materials that could help improve efficiency. One area highlighted by this examination was the installation of insulation. Specifically, the practice of filleting insulation used on small-bore pipes and fittings. In response to the market’s need, we have developed and tested an alternative type of fiberglass insulation – SSL II® with ASJ Max Fiberglas™ Pipe Insulation. Using this insulation can help reduce labor time by up to 16% by trimming or eliminating the time spent filleting insulation.2 The easy-to-seal adhesion process also helps reduce the need for additional products during binding and limits the potential of insulation to unseal. Overall, this innovative insulation can help reduce the time spent on an insulation project and labor-based costs.

Labor saving features to reduce pipe insulation installation time

Stress may be an inescapable element of a construction project, but a new style of insulation is looking to reduce the complications involved with insulating small-bore pipes and improve installation efficiency. Applying our flex core insulation on small bore pipes removes some of the steps traditionally involved with pipe insulation, potentially improving installer safety and saving up to 16% of installation related labor-hours.2 During large mechanical projects that require significant amounts of piping, insulation may be added toward the end of the project and is often a critical part of the schedule. Reducing the time needed and simplifying the installation process could limit chances for delays to occur and reduce costs for the project.

Examining industry efficiency

Globally, the construction industry is a major element of the economy. Annually, about $10 trillion is spent on goods and services related to construction, according to information from The McKinskey Global Institute report “Reinventing Construction: A Route to Higher Productivity.”1 However, the sector also has room to grow. One prediction indicates that if sector productivity improved it could add up to an additional $1.6 trillion or 2% GDP.

The construction sector faces multiple challenges to productivity which have slowed its growth. Globally, the sector has seen about 1% growth per year for the last 20 years, reported McKinsey. During the same period, the total world economy improved by 2.8% and the manufacturing sector saw productivity improve by 3.5%. Although there is a difference in the productivity of two different factions within the construction industry – large-scale projects, like industrial or civil facilities, and smaller-scale work, like specialized projects or single-family housing – even the larger and more productive part of the sector continues to encounter problems that hinder productivity and growth.

The assessment of the industry determined that actions taken to improve productivity should apply to the entire supply chain and include both small and large projects. It also found there are seven major areas for improvement, including:

- Revising regulation

- Changing the contractual framework to address industry dynamics

- Revamping the design and engineering processes

- Streamlining procurement and supply-chain management

- Improving on-site execution

- Employing more digital technology, new materials and automation

- Updating workforce training

Understanding that development and innovation are needed to help move the industry forward, so we looked at what we could do with insulation to help reduce the time projects took and see if we couldn’t simplify some elements involved.

Disrupting insulation application

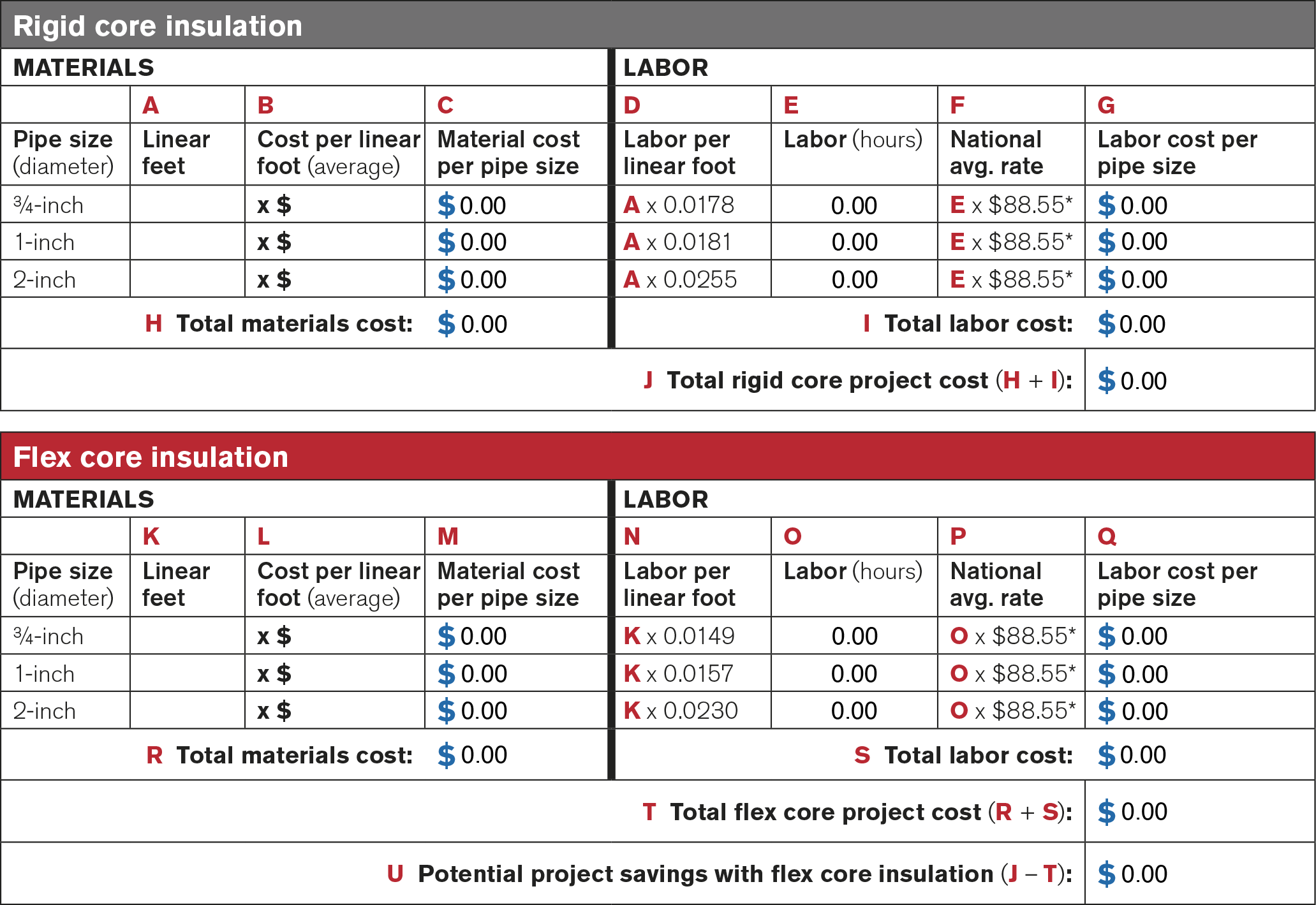

To better understand the time-saving potential of changing how pipe insulation is installed on small-bore pipes and the practical effect of eliminating the need to fillet, we partnered with RSMeans to design a study measuring installation time and labor hours spent on application.

The comparison trial designed featured a range of ¾-inch, 1-inch and 2-inch copper piping installed at different heights in bent, horizontal and vertical placements. A two-person crew of pipe insulators who had about five years of experience installing insulation was asked to install three different types of insulation on the piping during a three-day window. One type of insulation was installed each day using standard tools and practices. Their performance was measured and the number of productive labor-hours per task were calculated.

Overall, removing the need to fillet the insulation so it would fit on elbows, couplings and tee-sections did increase the speed of installation. Regardless of pipe size, the flex core insulation was always faster to install. With the ¾-inch pipe, for example, installing flex core insulation provided savings of 0.05 labor hours compared to competitor 2 and savings of 0.28 labor hours compared to industry competitor 1. On average, this was a reduction of 0.165 labor-hours or 9.9 minutes off the total job time.

While a few minutes of time saved may not appear significant, it is important to apply the results to a commercial-scale project. The savings as they relate to larger-scale projects could influence the profitability of the project. Applying the trial’s findings to a take-off/estimate from a six-story building spanning about 162,000 square feet found a total savings of 31.91 labor hours or $2,825.63 based on an average per hour billing rate of $88.55.2

Sealing the deal

An additional feature of the insulating material is the nature of the SSL II double-adhesion closure system used with the flex core insulation. Once the release liner on the adhesive strips is removed, the two layers of adhesive are pressed firmly together and smoothed to ensure the seal will provide a tight, closed seam. The closure will be strong initially and continue to strengthen for the next 24 hours. The double adhesion eliminates the need for additional mastics, glues or staples to be used during installation. In comparison trials, the double adhesion was not found to reopen following the sealing process; some competing products did.

Conclusion

Addressing productivity constraints facing the construction sector means embracing new technologies and practices – and cutting out those slowing down projects. It’s time to say goodbye to filleting when applying insulation to small-bore pipes.

Here is more information regarding the use and installation of our SSL II® with ASj Max Fiberglas™ Pipe Insulation.

Related Articles

Related Articles

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Jump to a Solution Suite

Jump to a Solution Suite