- Moisture

- Commercial

- Blog

Versatile VRAs: The role of XPS in VRA function and design

Blog in Brief

VRA with XPS: in short

Vegetative roof assemblies (VRA) are popular additions to commercial buildings for several reasons, including that they can provide environmental, economic and enrichment benefits for the facility. As extreme weather events increase, VRAs can help mitigate some of the potential damage these events cause. However, care needs to be taken when selecting the insulation used to support a VRA. Insulating elements sitting under the vegetation need to provide high compressive strength and be moisture resistant. The combination of these elements is why our Foamular® extruded polystyrene insulation (XPS) is often used in VRAs and recommended for use by the National Roofing Contractors’ Association of America.

Versatile VRAS: The Role of XPS in VRA Function and Design

Installing a vegetative roof assembly (VRA) on a commercial building can be a way to provide a garden or green space in an urban environment. VRA installations provide multiple additional benefits including helping to lower heating and cooling costs* for a building, protecting the roof membrane to extend the life of the roof, reducing stormwater runoff and limiting the creation of urban heat islands. Adding VRAs also may help building seeking specific levels of LEED® certification.

*Actual savings may vary.

While designing a VRA can be a straightforward process, multiple factors must be considered for an effective and efficient VRA design. Moisture and strength are two such factors, and selecting the correct type of insulation can address both needs.

XPS and moisture

Vegetative roof assemblies are often used to manage stormwater runoff – a task that is becoming more critical as the number of severe weather events increase. In recent years strong storms have become a more common occurrence ranging from hurricanes that bring multiple inches of rain, to flooding and strong windstorms. During 2021, the U.S. experienced 18 weather events costing more than $1 billion in damages before the end of the year, according to the National Oceanic and Atmospheric Administration (NOAA).1

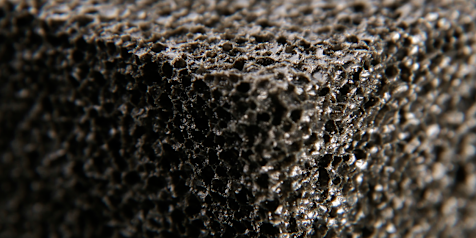

VRAs can help mitigate some weather-related challenges – like rain or stormwater. However, to manage water most effectively, the VRA needs to be correctly designed with a multilayer structure that includes a waterproofing membrane, insulation, growing media, drainage and pavers. Lightweight XPS insulation is a great fit for these designs as it does not readily absorb moisture and has demonstrated a 0.3% maximum water uptake by volume using ASTM C272 – Standard Test Method for Water Absorption of Core Materials for Sandwich Constructions - and specific types of the insulation are even fabricated to help channel water.2 The material also provides up to 100 psi of compressive strength to support the weight of vegetation and roof traffic.

XPS at work in VRAs

One feature of the design process for a VRA is customization. Depending on the size of the building and the goal of adding a vegetative roof display, the top layer can look very different even if the supporting materials are the same. Our XPS insulation has been used in a range of VRA projects including:

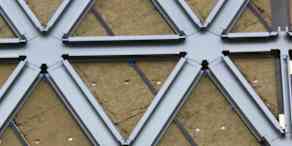

The U.S. Coast Guard Headquarters – This 300,000 square foot VRA tops an 11-story office building equipped for 3,860 employees, a central utility plant and two parking garages. The project also incorporates a 120-foot elevation change across the site. In addition to other positive elements from having a roof-top garden, the VRA was intended to help the site reach LEED® Gold certification.

Both Foamular® 404 and 604 XPS insulations were used in the VRA to provide integrity and support the roof’s long-term performance. The VRA includes a range of vegetation – sedum mats, grasses and shrubs – installed in stages.

The Wharf in Washington, D.C., – A new building project in a river front area of Washington, D.C. decided to install a series of VRAs to address the city’s requirements for managing stormwater runoff. The city requires facilities to manage and retain runoff from 1.2” storm events. VRAs and cisterns are commonly used methods as they can capture and reuse stormwater. VRA installation also may be mandated based on the building’s footprint. The Wharf complex is almost a mile in length, includes mixed-use development and is intended to provide multiple green spaces at street-level and across several rooftops.

VRAs throughout the project are supported by Foamular® 404 and 604 XPS insulation because builders needed insulation that was water resistant and able to manage holding a range of coverings including plants, pavers and soil containing pedestals and basins. The high R-value our insulation helps with energy performance across multiple building enclosure areas on site. The water resistance provided by Foamular® XPS manages water flow and reduces the possibility that drainage systems would be overwhelmed. The insulation helpes channel water from the plant, growing media and filter or drainage layers to the water-resistant layer and into several overflow vaults installed for additional water containment.

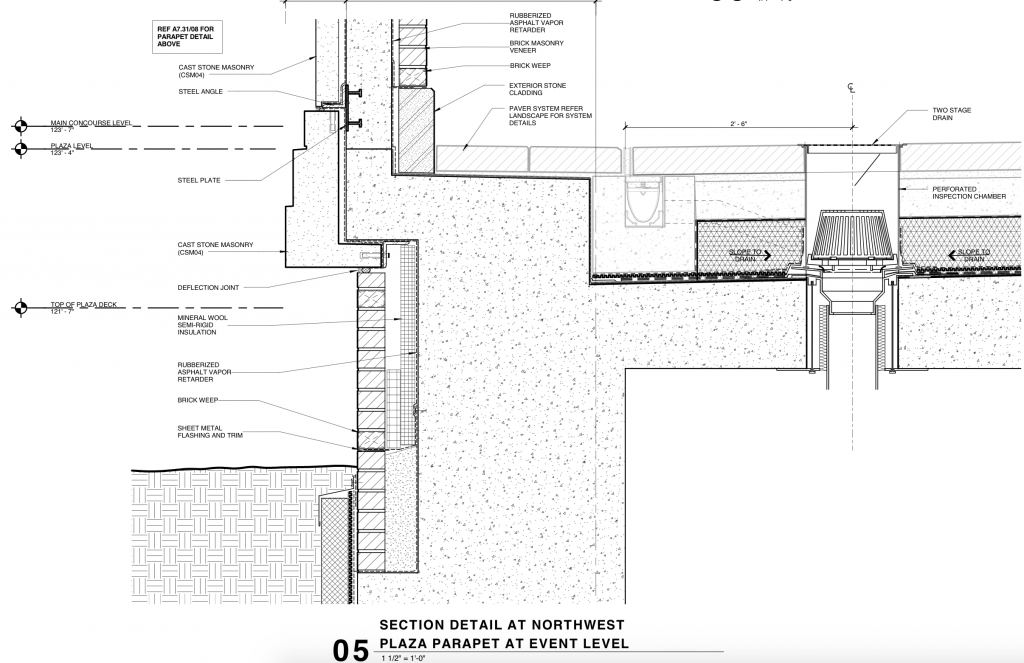

Dickies Arena Plaza Deck – Opened in 2019, the plaza deck of Dickies Arena provides a viewpoint for the Fort Worth, Texas, skyline and events occurring outside of the arena proper. However, the deck also demonstrates the range of abilities that XPS insulation provides. The outdoor area includes paved and green spaces intended to help manage stormwater runoff.

The site presented several unique engineering challenges including needing a lightweight insulation that could be water resistant and support vehicle traffic. The plaza deck can manage a weight load up to 25,000 pounds and needed insulation that could deliver at least 60 psi.

Additionally, the roof design needed tapered, flat and reverse tapered insulation to account for the slopes involved while providing water management. The combination means that the installed insulation ranges from 3 to 13 inches across the plaza. The reverse tapered section helped balance out the slope of the roof toward main drains, the flat section increased the height without adding weight, while the regularly slopped area is intended to channel water to the inconspicuous surface drainage assemblies.

Regardless of how a VRA is intended to look when completed, each installation needs support and a way to manage moisture. This combination of needs is why so many successful VRAs include Foamular® XPS insulation.

References

Related Articles

Related Articles

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Jump to a Solution Suite

Jump to a Solution Suite