- Acoustics

- Mechanical

- Blog

Acoustic insulation solutions for industrial pipe applications

Blog in Brief

Increasingly, planning for industrial noise is becoming part of project design, rather than something added after. There are some challenges with this as the testing process for insulation systems designed to dampen noise is lengthy and expensive. A new theoretical modeling system built and validated following a series of in-lab tests provides a tool to assess acoustic insulation designs, shortening the development process and reducing overall costs. The model has been validated for use with up to the largest pipe sizes and found to be 90% accurate in class rating predictions.

Acoustic insulation solutions for industrial pipe applications

Life can be noisy, especially in industrial settings. However, there is a difference between low-level background sound and ongoing, workplace noise strong enough to be a risk to hearing. Globally, one in three adults have measurable hearing loss and about 1.1 billion younger people are at risk for hearing loss related to noise exposure, according to the Centers for Disease Control (CDC).1 The organization adds that occupation-generated noise remains a primary cause of hearing damage. In the U.S., National Health and Nutrition Examination Survey data suggests that 14% of adults from 20-69 years old — or about 27.7 million people — had measurable hearing loss, while the National Institute for Occupational Safety and Health (NIOSH) calculates that about 22 million workers face damaging noise levels in the workplace.1,2 Damage to hearing is a concern for several reasons according to the World Health Organization, as hearing loss can have negative effects on health, job performance, quality of life and speech-based communication.3

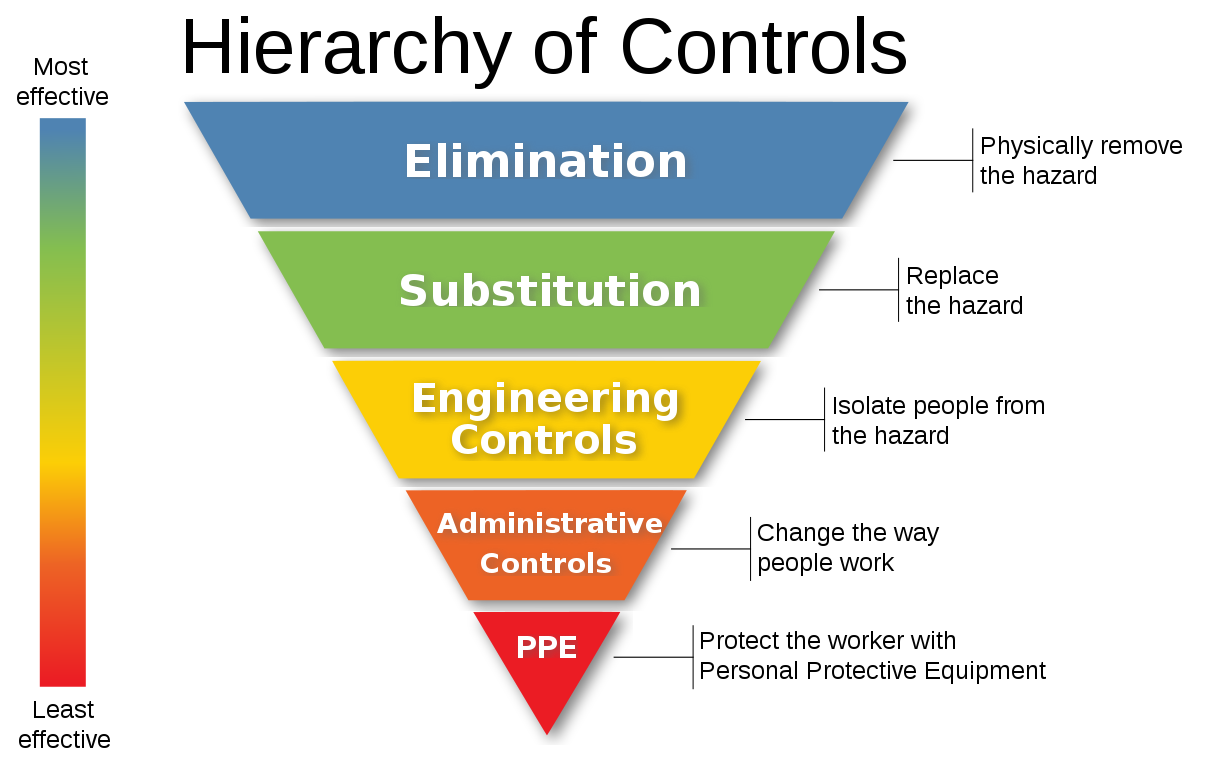

Acknowledgement of the challenges posed by hearing damage has prompted a range of interventions to help reduce the risk employees in industrial or loud businesses face – including NIOSH’s hierarchy of control and the Buy Quiet program, which seeks to support the development and installation of machinery that generates less noise. The hierarchy of control outlines a series of interventions that can be used to curb industrial noise or protect employees from repeated, long-term exposure to loud noises.2

Insulating employees from risk

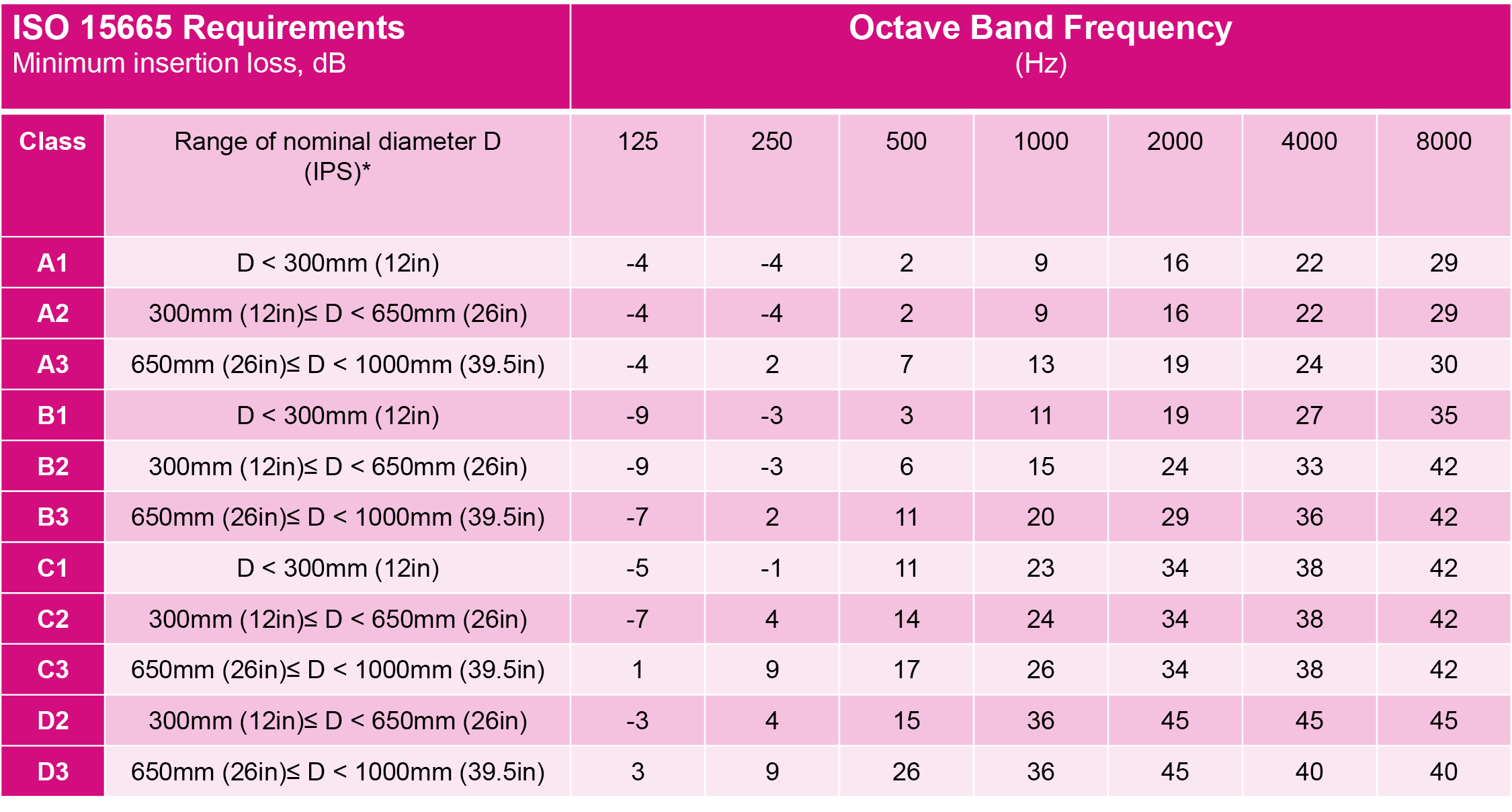

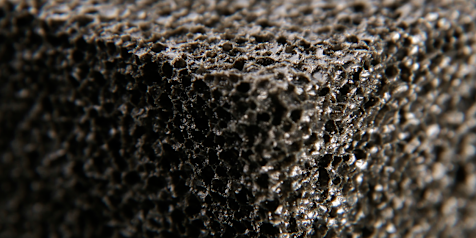

If a particular noise generating element cannot be removed or replaced with a quieter version, it may be possible to curb or reduce the amount of noise generated using engineering controls. For industrial piping, designing and applying the correct types of insulating systems can reduce the amount of noise released. How well insulating systems perform in terms of noise abatement has been classified by the International Standards Organization (ISO) in ISO 15665 — Acoustic insulation for pipes, valves and flanges — which established class A, B and C for pipes in three size ranges, up to 300mm, 300mm-650mm, and 650mm-1,000mm.4 A fourth class, D, is considered the highest level of acoustic performance for insulation and was established outside of the standard.

Figure 2 — A standard has been created to evaluate the performance of acoustical insulation for a range of industrial piping.

Unfortunately, there have been limited, publicly available, designs for industrial acoustic insulation. The testing process is lengthy and can be quite expensive. A recent series of in-lab tests on multi-layer insulating systems for medium-sized pipes found that each test cost about $3,000 and the whole process took about a year to complete. Additionally, only a few facilities can perform the test needed — especially for large scale pipes. A series of tests done in 2020 on larger piping established that there were two facilities interested in considering the project.

The testing process requires that a pipe be installed across the testing room with open ends extending into other spaces. Insulation can then be added and removed from the installed pipe and measurements taken. Most of the testing costs actually relate to the time spent on installation and adjustment rather than the testing. Once the pipe is installed, the amount of noise radiated into the testing room is recorded with and without insulation in place — the difference between the two measurements is the insertion loss and used to establish the class rating for the insulation system.

Given the understanding of how important it is to take proactive steps to protect employees and limit the risk of noise-based hearing damage and the difficulties inherent in the testing process it became clear that a new testing method would be useful for industry. As such, both the tests on medium-size pipes and large pipes were used to inform and validate the creation of a testing model. The theoretical model was intended to provide an accurate assessment of the insertion loss an insulating system would generate and to predict the class rating. Using a model would decrease the time involved during insulation design and greatly reduce the cost of the process, as the only in-lab testing necessary would be for the final design to validate the results.

Putting results to work, developing models

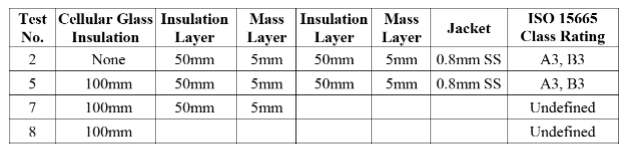

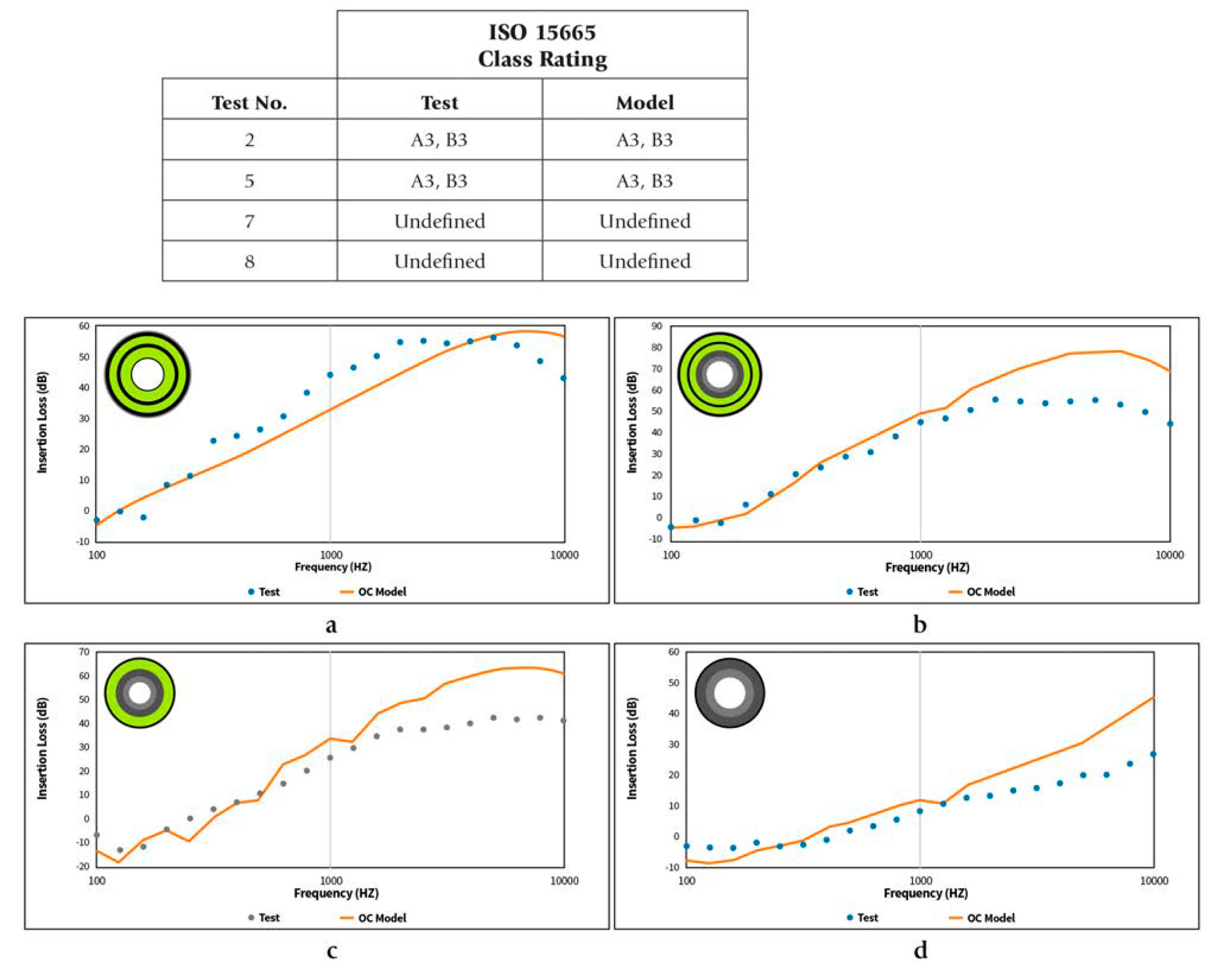

An initial series of 32 tests examined multilayer insulation systems intended for use with both hot and cold pipes and involving a changing mix of mineral wool, cellular glass, loaded vinyl and jacketings. The results were used to inform a statistical model that could be used to speed up the design and testing process. When validated, the model was found to accurately predict insertion loss between 100Hz and 10,000Hz with an R-sq(adj) value of 0.947. However, the statistical model only correctly estimated the class rating for the insulating system 66% of the time. Given this result, a second, theoretical model was created.

The second model used a one-dimensional model design and proprietary modeling software created by Owens Corning Acoustic Research Center.5 When the adjusted theoretical model was used to estimate the insertion loss from 100Hz and 10,000Hz it was found to have an R-sq(adj) value of 0.977 — an improvement on the initial statistical model. When used to predict class ratings for insulation, the model was accurate 90% of the time. In the instances where there was a difference, the model was consistently more conservative than the actual rating, meaning it would not generate negative surprises during in-lab testing. The second model was also used to examine insulation designed for large-scale pipes. It was validated against both prescriptive designs used in the ISO 15665 standard and a series of in-lab tests run at the Peutz Laboratory for Acoustics in the Netherlands. The adjusted theoretical model performed accurately during the validation trials, predicting class ratings that matched the in-lab testing.

Conclusion

While workplace noise exists in a range from background chatter to industrial machinery, increasing attention is being paid to the risk employees face from sustained, loud noises and the negative influences damaged hearing can have. This understanding has informed measures like the Buy Quiet program and NOISH’s hierarchy of controls. It also has prompted our assessment of insulation systems intended to provide noise dampening and the creation of a new theoretical model to estimate the performance and class rating of an insulation system. Having an accurate modeling system reduces the time and cost involved with designing and testing these insulating systems and should allow for additional design innovation and flexibility.

For more information about the work that Owens Corning is doing in the acoustic sphere register for this webinar where we talk about the changing role acoustics are playing in building design.

Related Articles

Related Articles

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Jump to a Solution Suite

Jump to a Solution Suite