- Fire

- Mechanical

- Blog

Protecting life safety in plenum spaces

Blog in Brief

Although they may not be immediately noticeable there is an important life-safety element to the materials installed in and running through plenum spaces. These recessed areas – often in the ceiling or below the floor – can spread toxic smoke or fire if the wrong types of uninsulated piping, cables or wiring are installed. The space is intended to aid facility airflow, which makes it a fire risk that must be considered. Several testing standards and code requirements have been established to guide the selection of materials used in these spaces. In addition to the life safety aspect, elements that are installed in or running through the plenum should be evaluated for ease of use, acoustical performance and hygienic maintenance.

Protecting life safety in plenum spaces

Ignorance isn’t bliss when it comes to the material used in plenum spaces. Whether created by the dropped ceiling in a conference room or the raised floor of a data center, the plenum space allows for additional air flow between rooms and may be a high oxygen space. It also provides a hidden home to wires, cables and piping. When planning to add and make use of plenum space in a building it remains important to consider its influence on the life safety features a facility provides.

Figure 1 — Ranging from elimination of loud noises to the use of personal protective equipment by employees, the hierarchy of control outlines a series of measures that could be used to reduce the risk of noise-based hearing damage.

Life safety measures or elements involved in life safety are those devices or installations used to protect human life should a catastrophic event occur, such as a fire in a high-rise building or multi-story commercial structure. A balanced approach to life safety measures provides the most support to a facility whether it’s residential or commercial in nature. A balanced approach does not rely on one type of life safety element but employs all three: detection, suppression through an active system, and passive systems.

Figure 2 — Life safety considerations in a facility need to assess multiple performance attributes. Correctly examining, designing and installing passive fire protection in out-of-sight plenum areas is a critical component of protection.

When deployed together these elements interact to give employees or residents the best chance to evacuate the building, while providing time for the fire to be extinguished. Detective elements include smoke and heat detectors that provide an alert when a safety hazard occurs. Active systems require some trigger to turn on and could include suppressions systems or sprinklers. Once installed, passive systems are always in place and do not require activation. Correctly protected, designed and installed materials in plenum areas help address facility life safety by reducing the generation of smoke or preventing the spread of fire.

Fire damage and plenum standards

The rules and standards governing materials that can be used in plenum spaces have evolved over time, with changes often triggered by catastrophic events. One early fire that prompted more awareness of materials in these hidden, air-flow areas occurred in the North Tower of the World Trade Center in 1975. The incident highlighted how plenum area cabling – in this case telephone wire – could allow fire to move. An analysis of the fire done by The New York Board of Underwriters reported that “The worst and most hazardous condition is when wires and cables with combustible insulation are run through plenums to service the floor above. This provides a double hazard by introducing combustibles into the air conditioning.”1 While one cable may not burn, the report added, a cluster of cables can maintain a “substantial fire” like the effect provided by a collection of logs.

Following the fire, agencies like Underwriters Laboratories (UL) started to create tests to examine the fire safety of plenum areas and changes were made to the International Building Code and International Mechanical Code.

Plenum regulations

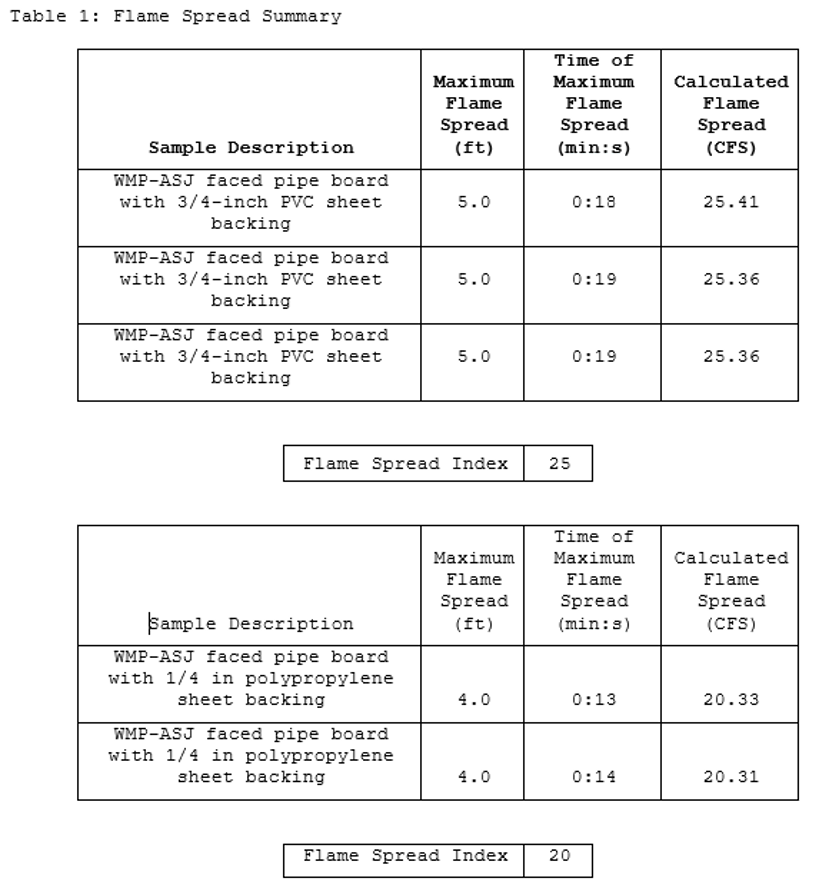

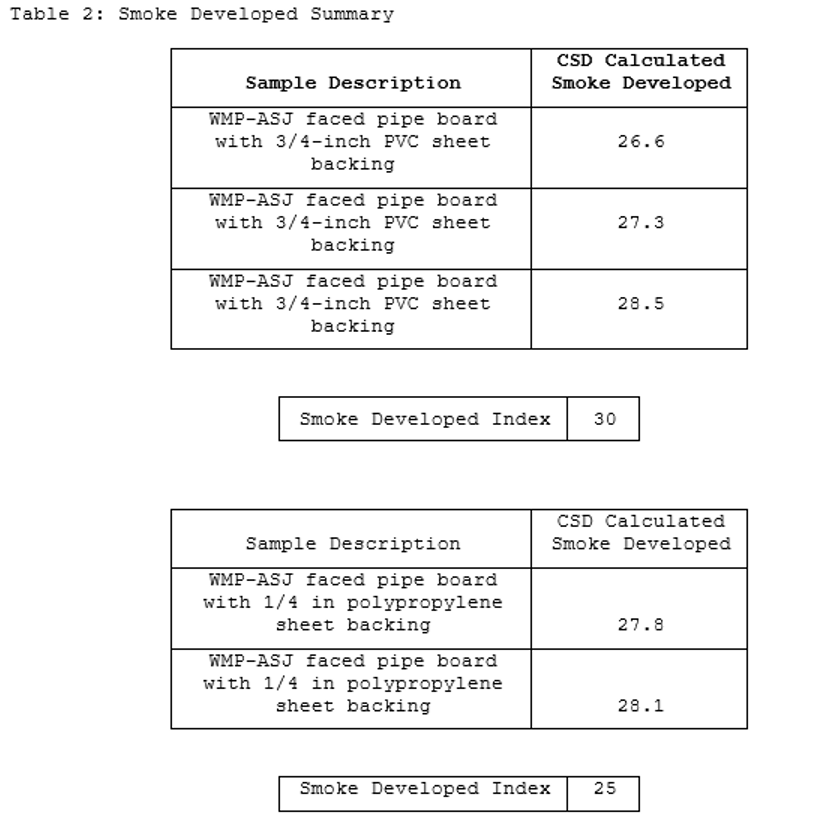

The International Mechanical Code addresses materials used in plenums in section 602.2.1 from 2012, 2015 and 2018. According to the code section, the elements running through the hidden space need to be noncombustible and be listed and labeled as having a flame spread index of not more than 25, with a smoke developed index of not more than 50 — as determined by testing using ASTM E84 — Standard Test Method for Surface Burning Characteristics of Building Materials — or UL 723 — Standard for Safety Test for Surface Burning Characteristics of Building Materials. The exception to the code — exception 5 — only applies when the materials running through the space are fully encased within a material that has been listed and labeled for use within the plenum.

However, both testing standards, ASTM E84 and UL 723, are not used to determine hourly fire-resistance ratings. Instead, the testing standards relate to a material’s response to fire. They are used to establish flame spread and how much smoke is generated by items being tested. ASTM E119 — Standard Test Methods for Fire Tests of Building Construction and Materials — or UL 263 — Standard Fire Tests of Building Construction and Materials — are used to generate fire-resistance ratings.

Today as code and standards call more attention to materials in the plenum space, there is an understanding that not addressing this area correctly could be a legal liability, generate expensive and potentially extensive replacement work, and, in the event of a fire, increase hazards by generating toxic smoke and allowing for fire spread.

Material considerations

When selecting materials to use in plenum space, the first consideration must be that they meet life safety requirements. However, once that topic is addressed there are other factors to consider including ease of use, sanitation, and acoustic performance.

As plenum space is recessed — either above the dropped ceiling or below the floor — it can provide cramped working conditions. Selecting materials that are easier to use and, when used as a wrap or jacketing, provide a firm seal may reduce installation frustrations and prevent the need to repeat work to reseal materials already installed.

Another element to consider when selecting an encasing element for use in a plenum is how easy the material is to maintain. Plenum space acts as an airway, indicating that objects housed in the area should be clean. Any jacketing materials used need to be evaluated for thermal and moisture resistance along with hygienic properties. The ability to grow mold or mildew may not be a fire consideration, but it could be a life safety risk. A jacketing material like our SSL II® with ASJ Max Fiberglas™ Pipe Insulation can help address these elements as it is easy to install, provides a secure, double-adhesion seal without the need for staples or mastics and is easy to clean. The jacketing can be wiped off as needed to maintain a pristine appearance and hygienic outer layer. Additionally, the insulation has been reviewed for use in plenum spaces following testing by UL according to UL 723 and ASTM E84 and can be used to cover PVC and polypropylene pipe in those locations.

Figure 3 — Insulation intended for use in plenum areas should be considered first for its smoke and flame spread characteristics. Other elements to examine include how easy it is to use, how well it seals, what it takes to maintain the material and its acoustic performance.

Although potentially unrelated to fire safety, selecting acoustic performance for insulation used in the plenum can help reduce facility noise, providing a more comfortable work or residential environment. Although recessed, these areas tend to have multiple hard surfaces that would transmit sound waves and adding an element like mineral wool insulation could reduce the background noise radiation.

Conclusion

There are multiple elements to consider when running cables and pipes through recessed plenum spaces. While the first consideration needs to be life safety, evaluating other elements can help make the installation job easier, potentially prevent the need for rework and help support comfortable long-term use of the space.

For more information about our work in fire safety or life safety visit Owens Corning Life Safety.

Related Articles

Related Articles

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite