- Moisture

- Commercial

- Blog

3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Blog in Brief

When applying continuous insulation (ci) to the exterior walls of a building, it is important to consider what type of insulation is used and the benefits or challenges the material may bring. Using mineral wool as a continuous insulation brings flexibility to the enclosure design from a non-combustibility standpoint and provides three main benefits for moisture management. The first benefit is that mineral wool is vapor permeable, meaning it supports moisture movement preventing the buildup of condensation and related formation of mold or mildew, and helps protect against a double vapor barrier being installed. Additionally, the material is engineered not to absorb vapor, protecting its thermal performance even in humid regions, and it is barrier compatible, meaning it can be attached to an air or water barrier and continue to provide protection against moisture. These three moisture management attributes make our Thermafiber® RainBarrier® mineral wool a valuable component for use as continuous insulation in an exterior façade.

3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Continuous insulation can be an unsung hero of thermal performance and energy efficiency hidden in the exterior wall assemblies of structures. When continuous insulation is installed, the material stretches across all the structural elements – other than connections from fasteners and service openings – without thermal bridges or heat loss. By reducing thermal bridging, continuous insulation supports or maintains the R-value and thermal performance of walls to potentially help improve a building’s heating and cooling efficiency. It also supports a continuous resistance to moisture, as air and water barriers can be installed with continuous insulation without hindering performance, which helps reduce the potential for condensation to collect within walls.

Using Thermafiber® RainBarrier® mineral wool to provide continuous insulation in a building’s exterior wall assembly provides multiple benefits ranging from moisture management, fire resistance, sustainability and sound control.

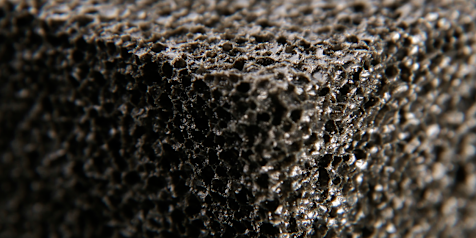

Benefit 1 – Mineral wool is vapor permeable

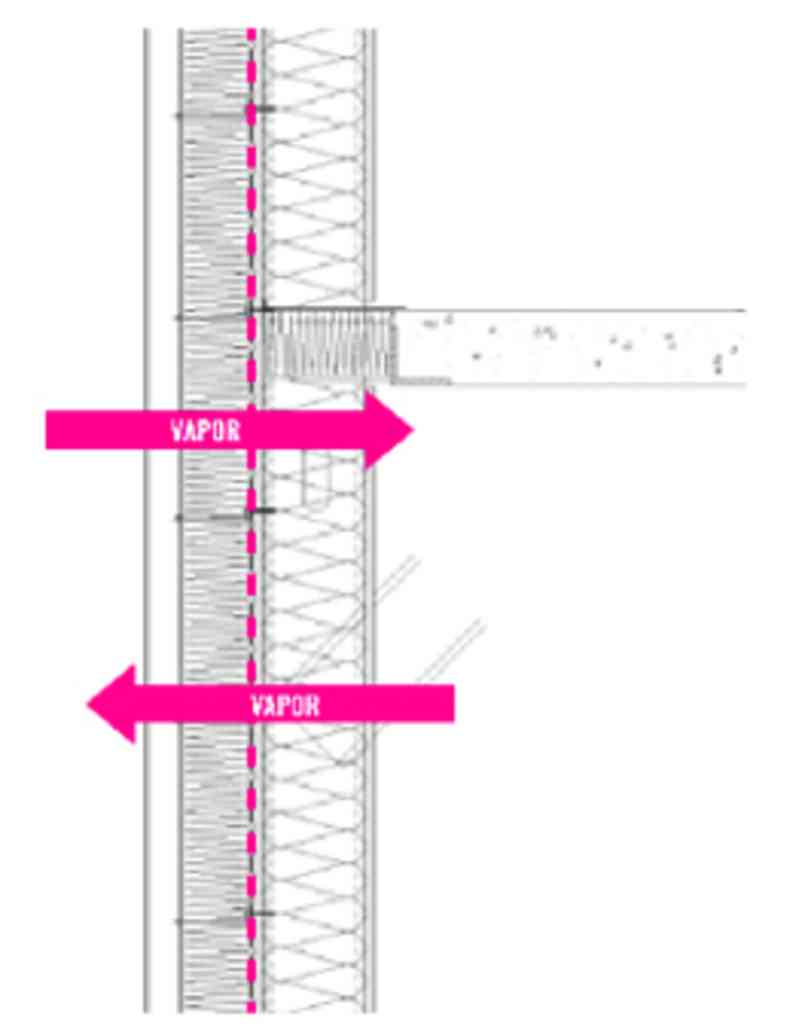

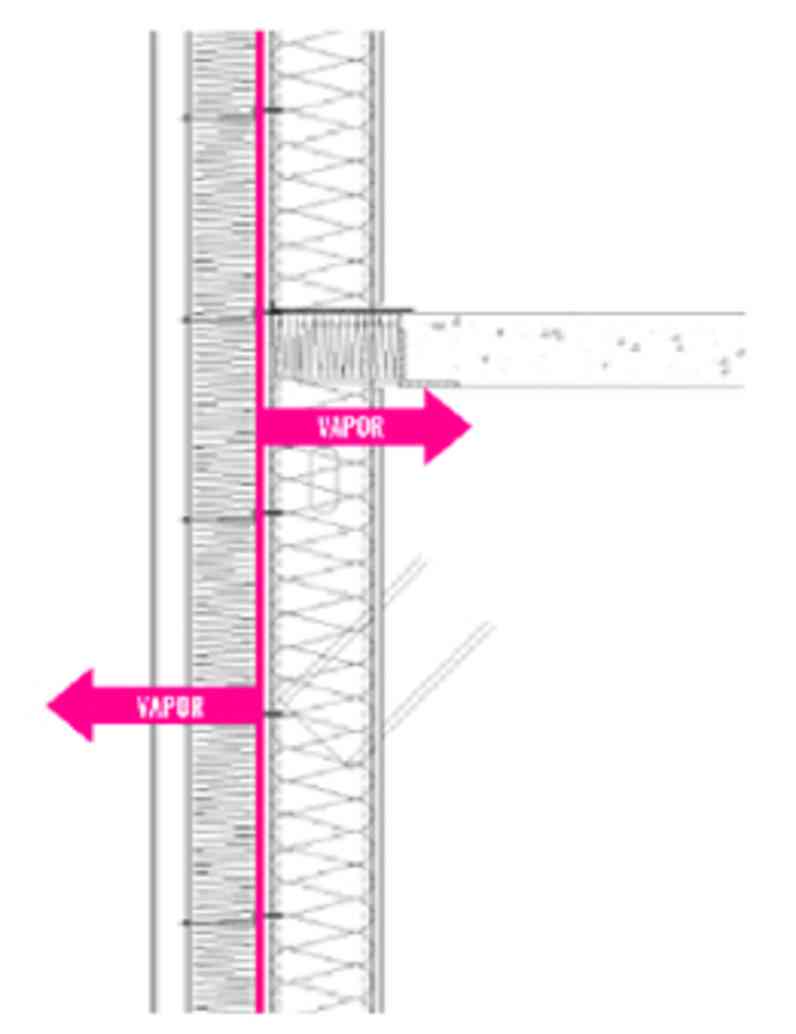

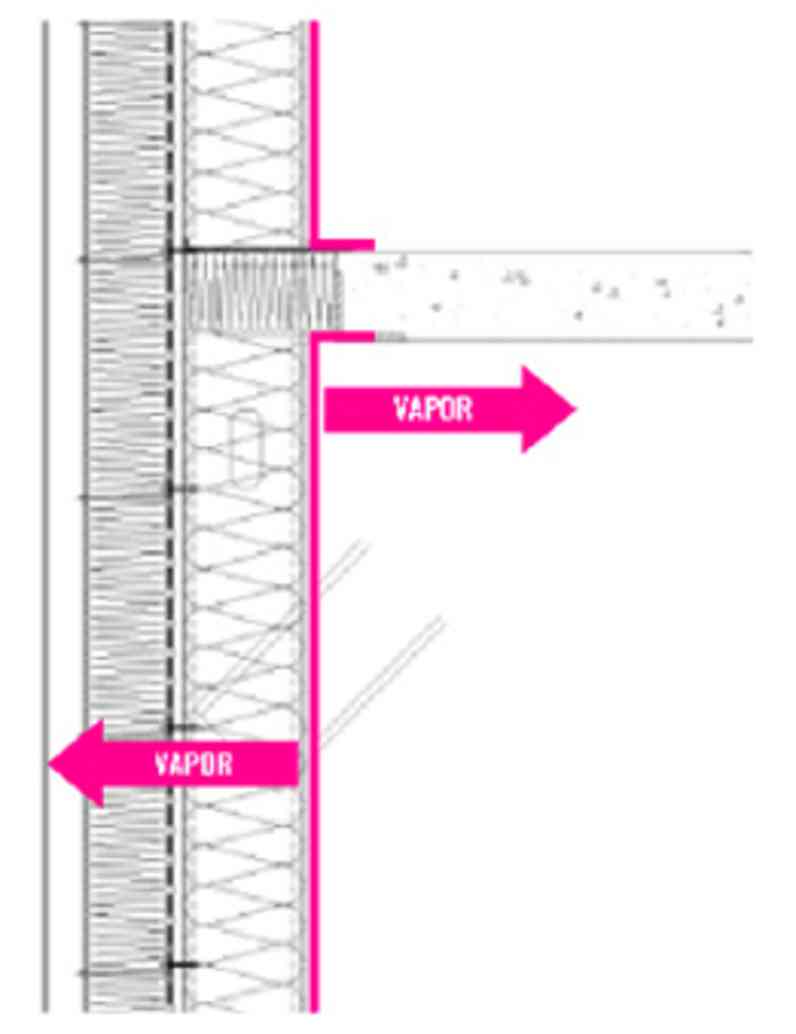

Mineral wool insulation helps provide flexibility to designers working on the exterior façade of buildings by reducing the possibility that a double vapor barrier will be unintentionally created in the assembly. The insulation supports vapor movement in a range of climates because it is vapor permeable.

When water vapor meets a colder surface, it will condense. There are situations where this is not a problem – or is, at most, an inconvenience – such as when the outside of a cold beverage starts to “sweat” on a warm day. However, when this occurs within an exterior wall assembly, it can lead to major problems, including mold or mildew growth, which can then potentially cause structural damage. These negative outcomes make it important for vapor and moisture to be provided a way out of the wall assembly before problems can develop, and installing continuous mineral wool insulation is one way to help manage this risk.

Taking steps to manage moisture flow helps prevent vapor from collecting and staying on internal elements of the wall assembly – like the interior side of exterior sheathing or the in-wall side of drywall. Thermafiber® RainBarrier® mineral wool has an average per rating above 50 (based on ASTM E96), demonstrating its permeability and ability to aid in vapor movement.1 Some types of insulation do not facilitate moisture movement to the point where they are classified as Class 1 vapor retarders or vapor barriers having 0-0.1 perms. When designing an exterior wall assembly, it is critically important to prevent vapor barrier materials from being on both sides of the wall assembly, a situation known as installing a “double vapor barrier.” This design can trap vapor and limit a wall’s ability to dry. However, incorporating vapor-permeable mineral wool insulation into the assembly helps prevent this from occurring by providing for moisture movement.

Mineral Wool CI Allows for Maximum Design Flexibility

Figure 1: Vapor permeable wall assembly with mineral wool ci and vapor permeable air and water barrier system.

Figure 2: Vapor impermeable wall assembly with mineral wool ci and vapor impermeable air and water barrier system.

Figure 3: Vapor impermeable wall assembly with mineral wool ci and vapor permeable air and water barrier system and interior vapor retarding membrane.

Benefit 2 – Mineral wool ci is engineered not to absorb vapor

Water is an excellent thermal conductor, meaning that any moisture trapped within insulation can lower the R-value thermal performance for the insulation. As the presence of moisture vapor can ebb and flow as air warms and cools, it becomes important for insulation to resist collecting or absorbing moisture to help protect thermal performance.

In addition to Thermafiber® RainBarrier® insulation being vapor permeable, it has also been designed to resist absorbing moisture. The insulation has a minimal sorption of 0.03% even when subjected to harsh, humid conditions like those created by ASTM C1104. This is the standard test method for determining the water vapor sorption of unfaced mineral fiber insulation and subjects materials to 120°F (48.89°C) temperatures with 95% humidity for several days.2 This rigorous testing helps demonstrate the insulation’s ability to maintain thermal performance throughout a range of service conditions. When applied as continuous insulation within a structure’s exterior wall, the consistent nature and performance of our mineral wool allows it to provide consistent thermal performance throughout the façade regardless of climate.

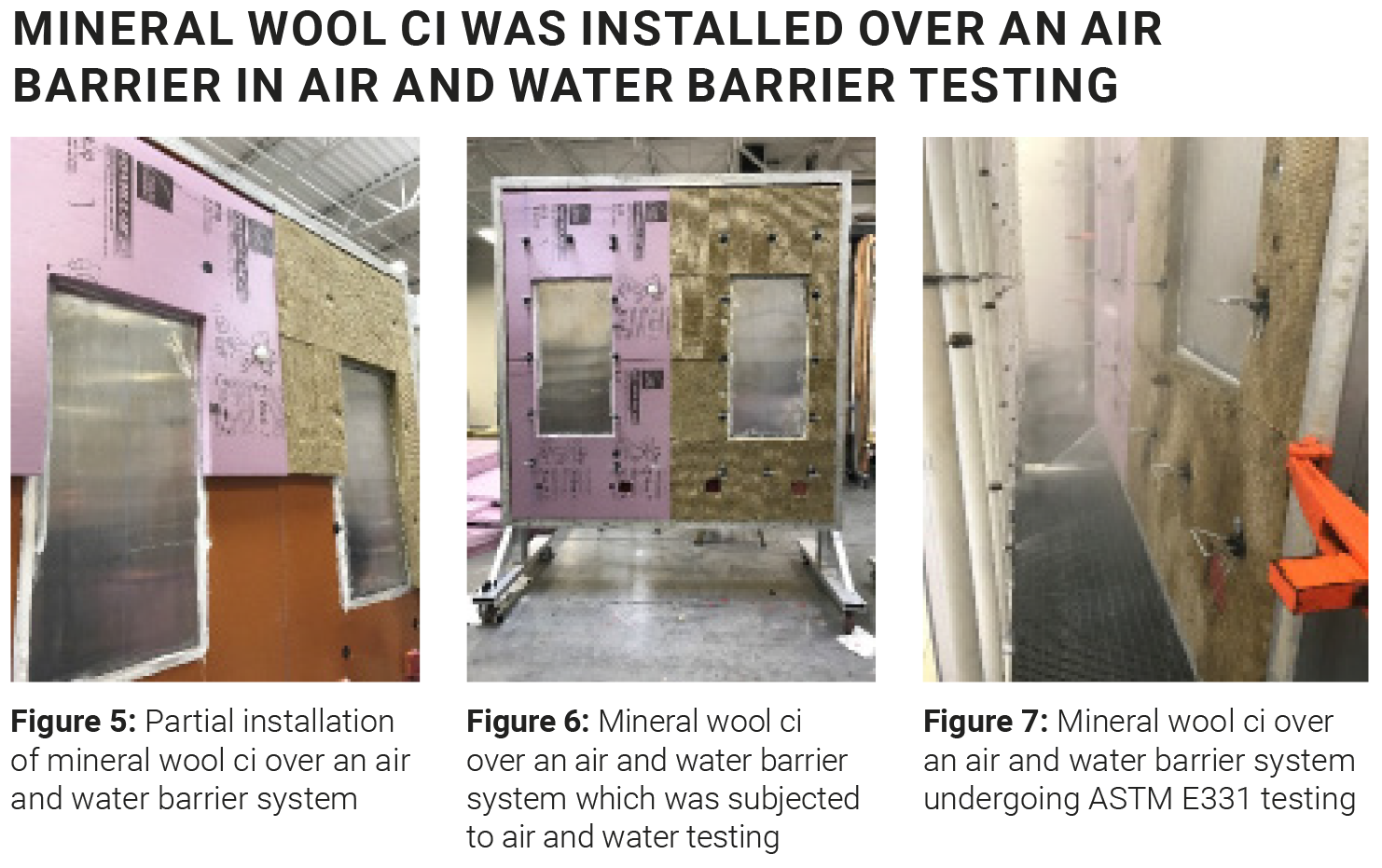

Benefit 3 – Compatibility with air and water barriers

There are several components involved in designing and installing an exterior wall assembly, of which mineral wool insulation is one part. We were curious about how well mineral wool worked once attached to an air and water barrier, which would be the case in a wall assembly. To test this, we used ASTM E331, the standard test method for water penetration of exterior windows, skylights, doors and curtain walls by uniform static air pressure difference.3 The sandwiched materials included in the test were our Thermafiber® RainBarrier® 45 mineral wool insulation over an STP Air & Water Barrier and next to XPS insulation.4

Overall, no difference was noted between the layered panel with mineral wool ci and the XPS panel. More specifically, the testing found that no leaks were reported for the duration of the test as stipulated by code criteria. Also, no leaks were noted following two hours of extended exposure to test conditions. Although extreme in nature, the testing helps demonstrate that, even when fastened in place, mineral wool can be used with an air and water barrier to provide moisture protection.

More than just water resistant

In addition to providing a high-quality hydrophobic performance, our mineral wool insulation has long been known for its fire resistance and non-combustibility. The insulation can withstand temperatures higher than 2,000°F (1,093.33°C) for more than five hours. As such, it is ideal for assemblies with combustible claddings, because it acts as an aid in passing NFPA 285. Additionally, our Thermafiber® RainBarrier® mineral wool continuous insulation comes in a range of compressive strengths to provide flexibility for designers working with a variety of claddings and attachment methods. The material can also help buildings address environmental sustainability considerations by contributing to credits in several green building programs.

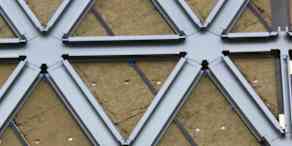

Mineral wool at work: Sidney & Lois Eskenazi Hospital

One project that has made use of our Thermafiber® RainBarrier® mineral wool is the Sidney & Lois Eskenazi Hospital in Indiana. The hospital has operated under several names and in different facilities since it was founded as the Indianapolis City Hospital in 1859, but in its most recent incarnation – it reopened in 2013 – the building relies on mineral wool to help protect it against moisture in the walls.

The LEED® Gold healthcare campus installed mineral wool within the exterior wall assemblies to manage liquid water and moisture vapor. The hospital’s location means moisture is a challenge as the region faces humid summers and has the potential for drenching rainstorms. Installing Thermafiber® RainBarrier® mineral wool insulation helps ensure that the exterior wall assembly effectively repels and expels water out of the wall cavity.

Conclusion

In addition to moisture management, our Thermafiber® RainBarrier® mineral wool continuous insulation provides fire-resistant attributes, reduces thermal bridging, improves overall R-value and supports building energy efficiency. Using continuous insulation can also simplify installation and reduce the need to penetrate the material.

Related Articles

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite