- Moisture

- Industrial

- Blog

Designing chilled water insulation systems to mitigate regional conditions

Blog in Brief

Chilled water systems help keep buildings at a desirable temperature, but they are subject to a range of risks across multiple regions. Inadequately insulated chilled water lines can increase facility costs, compromise cooling effects to the building and require higher maintenance needs. They can also be at risk of developing several kinds of damage, including mold growth and corrosion. There are several elements that must be considered when designing the insulation systems for chilled water lines. Factors that should be evaluated include local climate variability, possible extreme conditions the site may experience and the nature of the insulating materials. Using a closed-celled, impermeable insulation, like FOAMGLAS® cellular glass insulation, provides protection against moisture infiltration of the insulating system, helping support long-term, efficient system function.

Designing Chilled Water Insulation Systems to Mitigate Regional Conditions

Chilled water systems provide temperature regulation for various types of facilities, ranging from schools and data centers to office buildings and airports. They can be located indoors, outside or underground. Consequently, chilled water systems can be subject to regional conditions that can impair function and cause damage to the system if adequate safeguards are not taken. In coastal areas where systems are exposed to warm and humid environments, additional consideration should be given to the design of insulation systems.

Vapor Drive, Humidity, and Dew Point

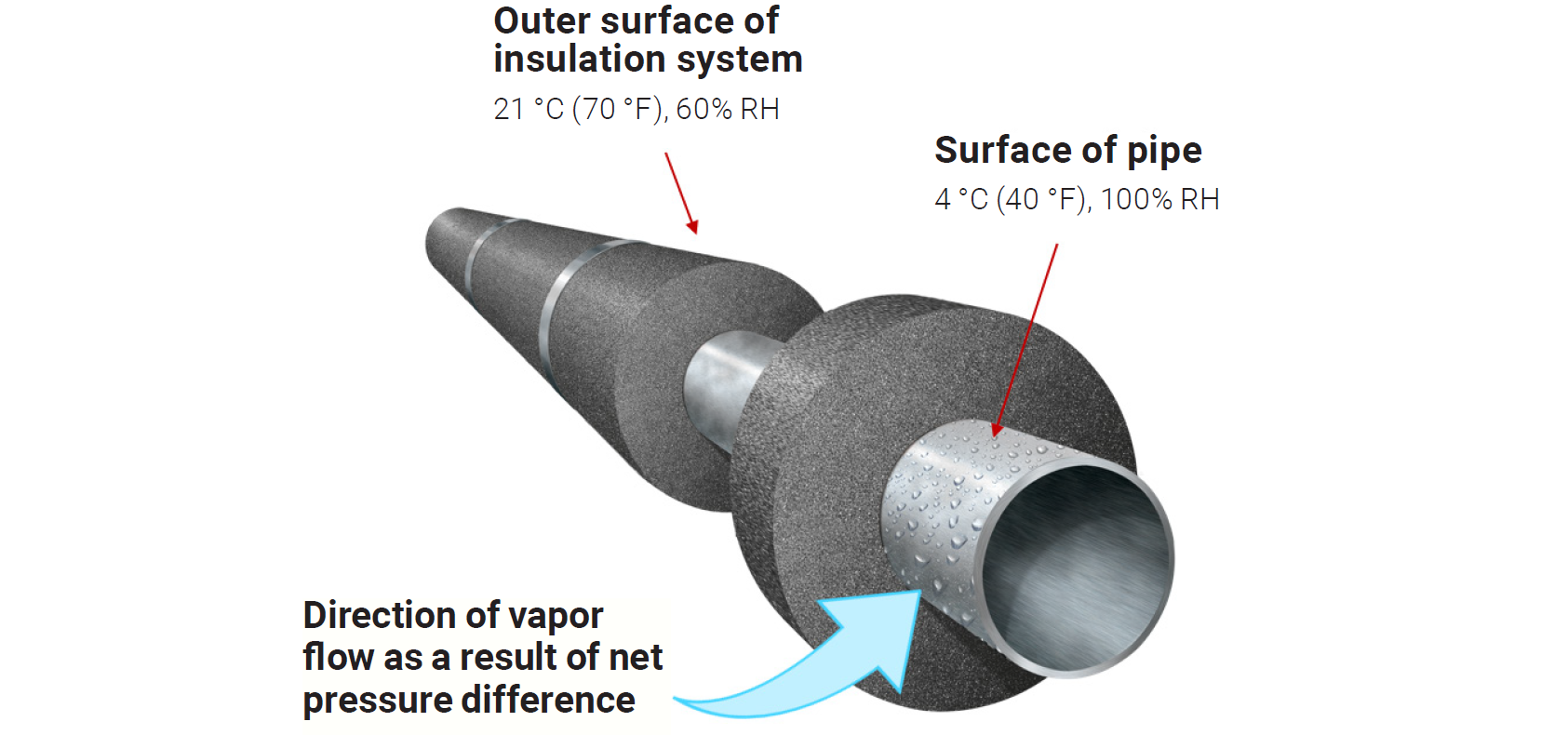

Vapor pressure is the pressure generated by a vapor that is in equilibrium with its condensed phase at a given temperature. As temperature increases, so does vapor pressure. As a result, high vapor pressure within warm air will tend to drive water vapor towards lower vapor pressures of cold air. This is referred to as vapor drive.

Humidity refers to the quantity of water vapor within an air space. Furthermore, relative humidity depicts the actual amount of moisture in the air compared to the maximum amount it could contain at that temperature and pressure. At 100% relative humidity, air becomes completely saturated and cannot hold any additional water vapor. Humidity will vary region to region as well as seasonally.

When the relative humidity is less than 100%, a dew point will exist at a specific temperature that is colder than the surrounding air. If the air drops in temperature below this dew point, water will begin to condense into its liquid form from the air. If objects are present that are colder than this dew point, they will cool the air and cause surface condensation or sweating to occur. With chilled water lines operating at temperatures of 2°C to 13°C (36°F to 55°F), surface condensation is a key aspect for chilled water lines to be designed around.

Warm air can carry more moisture, which could lead to increased condensation around a chilled water system. This becomes a notable challenge in places like coastal locations where high humidity is prevalent.

Another common issue chilled water systems face is moisture ingress into the insulation system. Damage to chilled water lines can begin during construction if systems are turned on before the building is enclosed, allowing for moisture buildup or penetration. In these cases, wet insulation should promptly be replaced, a process that can cost as much or more than the initial installation. The presence of moisture in an insulation system can also cause a range of problems, from increased system operating expenses or higher energy usage to raised maintenance costs and unplanned shutdowns.

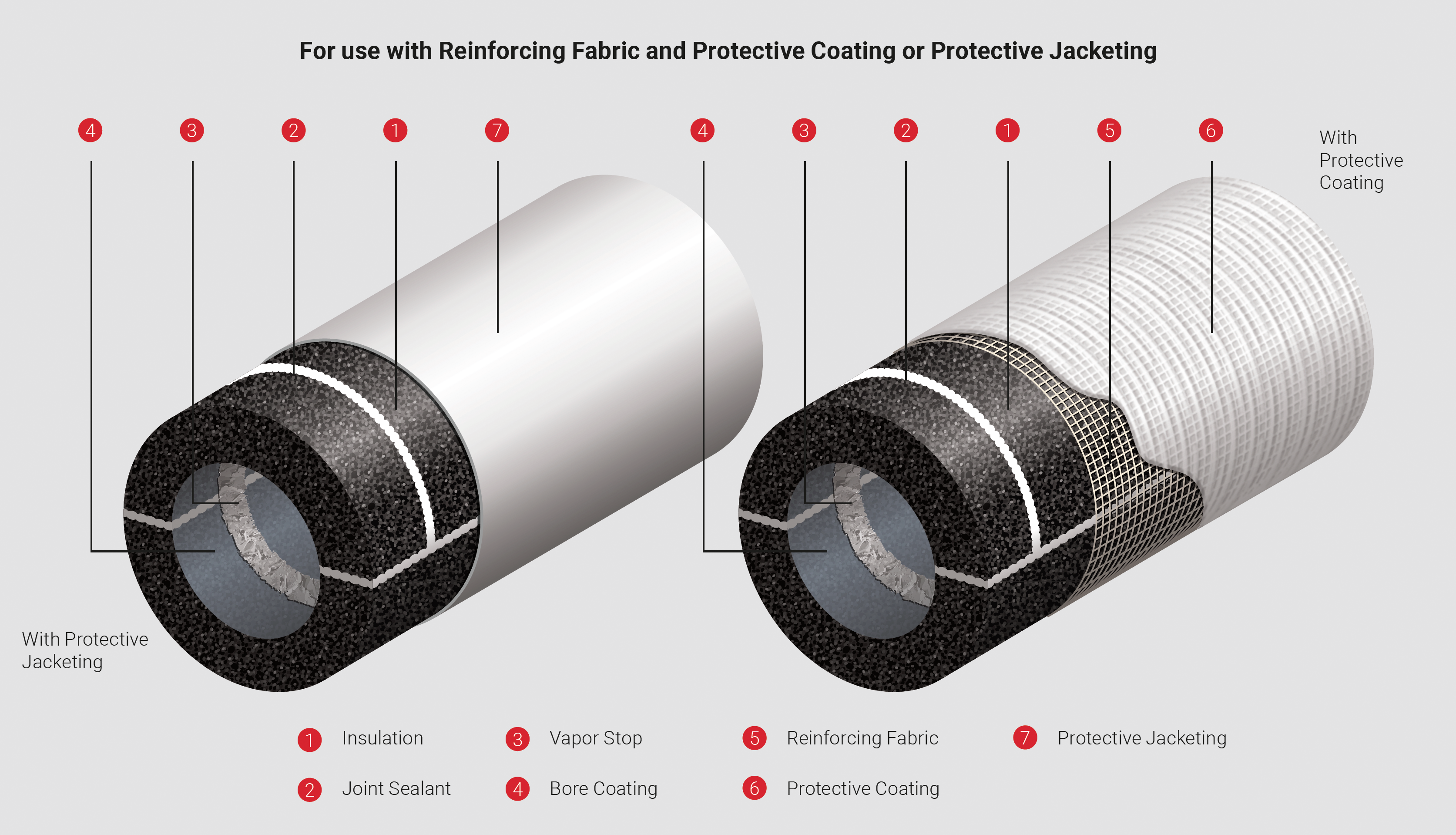

Damage to chilled water systems can be avoided by exercising proper care and consideration when designing the insulating system. This includes careful consideration and selection of appropriate materials, such as impermeable cellular glass insulation.

Insulation System Considerations

A key location where surface condensation becomes an issue is on the surface of the insulation. The surface of the insulation system will have a lower temperature than the surrounding air because of the chilled pipe underneath. One way to mitigate this consequence is to increase the surface temperature above the dew point by applying insulation in a sufficient thickness.

Another element to consider is the emissivity of the outermost layer of the insulation system. Emissivity is how well a material emits or absorbs heat through radiation and is expressed as a ratio between 0 and 1. The higher the emittance, the more heat that will absorb into the outermost surface from the surrounding environment. This means higher emissivity jacketing will yield higher surface temperatures, mitigating the risk for surface condensation.

It’s important to remember that insulating systems must be designed for severe temperature events, not only average ambient conditions. Failing to prepare for extremes could leave pipes exposed to conditions where sweating or condensation could occur for multiple days. Again, effective insulating and jacketing of chilled water pipes can help protect against extreme temperature fluctuations.

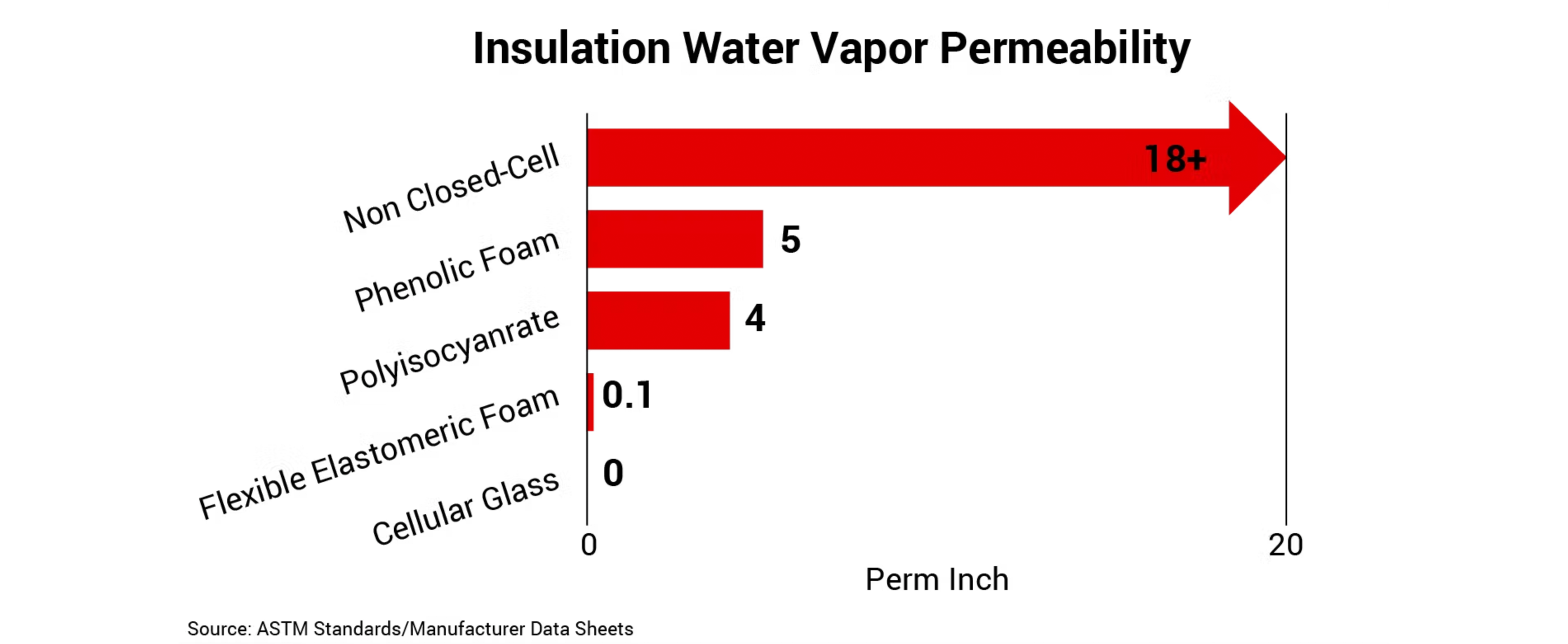

In addition to surface condensation, moisture ingress into an insulation material is also a concern. The vapor permeability of a material shows how readily water vapor can diffuse into it. Low and/or zero permeability insulations will better resist vapor drive that could force moisture into the insulation system.

Identifying Moisture Damage

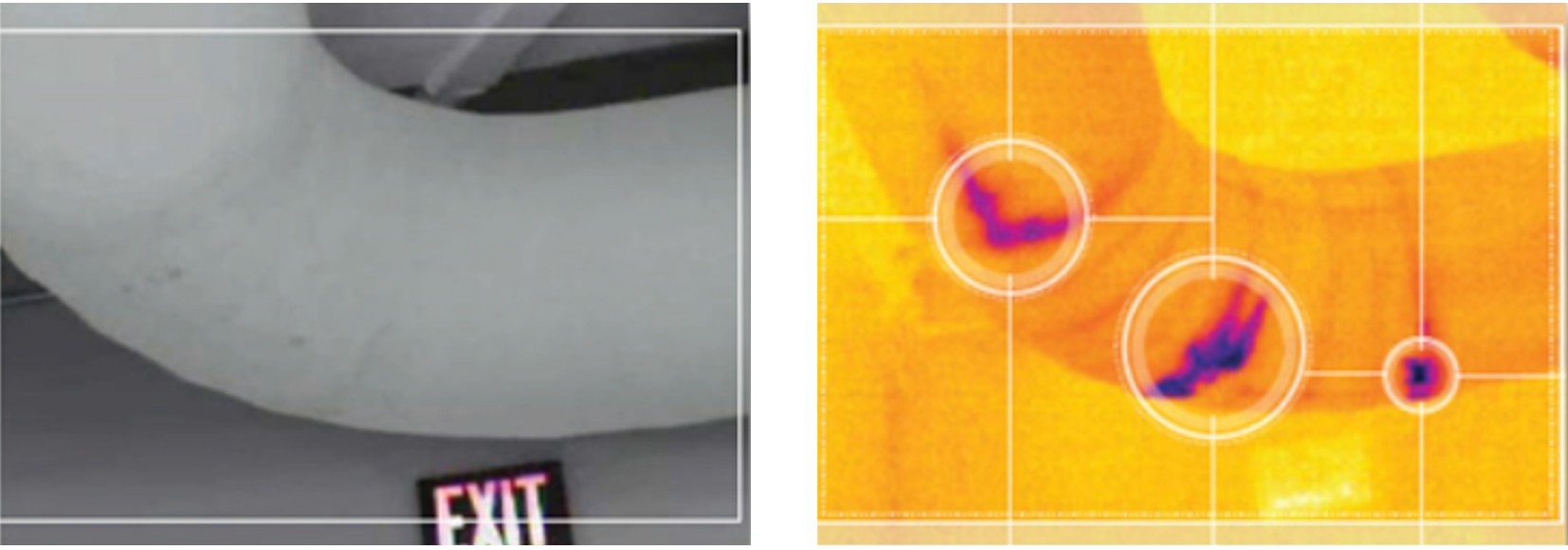

There are several kinds of damage that can occur when moisture penetrates an insulation system on chilled water pipes. The degradation tends to split into easy-to-spot problems and harder-to-find issues.

If an insulation system using permeable insulation is compromised, the material can start to absorb and retain moisture. If the insulation becomes saturated, it may start to drip water, a visible, external sign of moisture intrusion. Dripping water may also damage ceilings, walls or other equipment, depending on where pipes are located. The presence of moisture also increases the risk for mold and mildew growth. Mold growing indoors has been linked to several health challenges and can negatively affect indoor air quality.1

Other consequences caused by moisture penetrating the insulation on chilled water lines can be harder to see. For example, moisture retained within insulation reduces its overall thermal efficiency. A series of studies found that adding as little as 1% moisture to permeable or open-celled insulation increased its thermal conductivity by as much as 23%.2,3 A loss of efficiency means the cooling system must work harder to maintain specified temperatures, stressing the chillers, increasing energy usage and increasing operational expenses, plus potentially increasing maintenance needs while decreasing system lifespan.

Additionally, moisture in insulation can allow condensation to form on the outer surface of chilled pipes, leading to the development of corrosion under insulation, unexpected system failure and increased maintenance needs. Repairing pipes, especially in commercial buildings, often requires removing drywall, ceiling tiles and other components that block pipe access.

Considerations for Insulation Selection

Attention to proper selection and installation of insulation system components is important, since incorrect installation or improper design can result in poor performance during startup, restart or severe conditions. Using an insulating material with low permeability is one way to promote long-term, efficient function of chilled water systems.4

One example of a low-permeability insulation that could be used in these systems is FOAMGLAS® cellular glass insulation. The insulation is impermeable to moisture vapor and will not wick or absorb water. This rigid, lightweight material is made of completely sealed glass cells and it can be fabricated into a range of shapes. It can be used on piping and equipment above and below ground, indoors or outside. It remains dimensionally stable when exposed to a variety of temperature and humidity conditions and has an operating range from -268°C to 482°C (-450°F to 900°F). In addition, FOAMGLAS® cellular glass insulation is inorganic, so it will not support the growth of mold or mildew and is resistant to vermin.

Conclusion

Chilled water lines exist in a variety of environments, which can present a wide range of challenges. However, taking steps to properly design and install insulation can help mitigate many of the moisture-based risks that chilled pipes face. Using impermeable insulation, like FOAMGLAS® cellular glass insulation, is one way to help mitigate the danger posed by moisture, protecting the long-term, efficient function of cooling systems.

For more information about chilled water insulation system design, contact our global technical services and training team or visit FOAMGLAS® Chilled Water Systems.

References

- National Center for Healthy Housing. (2021). Mold. https://nchh.org/information-and-evidence/learn-about-healthy-housing/health-hazards-prevention-and-solutions/mold/

- Kehrer et al. (2002), Cremaschi, Cai, Ghajar et al. (2012), Jerman and Cerny (2012).

- Gusyachkin, A.M. et al. (2019). IOP Conf. Ser.: Mater. Sci. Eng. 570012029.

- ASHRAE Handbook — Fundamentals. (2017).

© 2023 Owens Corning. All rights reserved.

Related Articles

Related Articles

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Jump to a Solution Suite

Jump to a Solution Suite