- Moisture

- Commercial

- Blog

7 Key Factors for Selecting Commercial Roof Insulation

In a commercial roof assembly, insulation is a key element that works alongside other components to support overall system performance. Selecting the proper commercial roof insulation requires matching the insulating material to the roof slope, membrane type, climate zone, and building use so the entire system functions as intended.

The Benefits of Proper Insulation in Commercial Roofing

Proper insulation in commercial roofing acts as a barrier against unwanted heat flow, moisture intrusion, and uncontrolled air movement. By working in tandem with the membrane, roof deck, and other system components, the roof insulation helps extend roof life, improve energy efficiency, and maintain consistent indoor comfort.

1. Determine the Roof Slope and Type

What are the Most Common Roof Types? Low Slope Versus Steep Slope

When selecting commercial roof insulation, one of the first considerations is the type of roof slope. Roofs generally fall into two categories: steep slope and low slope roofs. The slope of the roof influences the type of insulation used, the roofing materials selected, and the installation methods that work best for the system.

Steep slope roofs are pitched or curved roofs that are commonly finished with materials such as asphalt shingles, metal panels, or historic materials like slate and cedar shakes (often fire-treated). In these systems, insulation is typically placed inside the building envelope, often in the attic floor rather than directly under the roof deck. Options may include fiberglass batts, cellulose, or spray foam. Spray foam is sometimes applied directly to the underside of the deck to create a fully enclosed, insulated attic. This method is gaining popularity in warmer climates and where HVAC equipment is located in the attic space.

Low slope roofs are often referred to as flat roofs, though code requires a slight slope. These roofs are designed with slopes of at least one-quarter inch per foot, with some membranes requiring steeper slopes. Building codes for roof assemblies outline specific slope requirements for different membrane types, with some materials able to function at lower slopes than others. The minimum slope depends on the membrane type and its ability to handle ponded water. The choice of membrane, in turn, impacts insulation compatibility and placement within the assembly.

2. Consider the Roof Assembly Design

What are the Components of Roof Enclosure Systems?

Roof enclosures are made up of several integrated layers, each serving a specific role in protecting the building and supporting long-term performance. The placement and compatibility of these components determine how well the system manages heat, air, and moisture.

The Configuration of a Roof Enclosure Includes:

- Roof deck: The roof deck is a structural base, usually concrete, wood, or metal for commercial projects, that supports the entire roof assembly. The type of roof deck affects attachment methods, insulation compatibility, and overall system design. Think of the roof deck like the floor of the roof; it is the foundation everything is built on top of.

- Air/vapor barriers: The air and vapor barriers are the layers that control the movement of air and moisture vapor into or out of the roof system, helping prevent condensation and protecting insulation performance. An air barrier primarily stops uncontrolled airflow, while a vapor barrier resists the passage of water vapor through the assembly. These barriers keep outside elements out to help keep the indoor elements of the building stable.

- Insulation: Commercial roof insulation is the thermal layer that reduces heat transfer, supports energy efficiency, and can add compressive strength to the assembly placed above or below the membrane, depending upon the particular roof assembly. The insulation helps keep building temperatures stable year-round.

- Membrane: The roof membrane is a waterproofing layer that protects the building from water intrusion. It shields the building from too much moisture. Membrane type is often a key influence in insulation placement and selection.

- Overburden/ballast: Ballast is heavy material that’s placed on top of the roof to hold everything in place. Imagine you lay down a blanket on a windy day; if you don’t put something heavy on it, it might blow away. That’s what ballast does for roofing systems. Overburden and ballast are materials such as pavers, stone, or vegetation placed above the membrane or insulation to protect against UV exposure, secure components, and add durability.

How Does the Insulation Placement Affect the Choice of Roof Enclosure System?

Since each layer in the roof enclosure contributes to the system’s overall performance, the location of the insulation within that assembly becomes a critical design choice.

Insulation in a commercial roof system can be installed either below the membrane or above the membrane (PRMA or protected roof membrane assembly). In conventional systems, the membrane is the final exposed surface, while PRMA systems place insulation above the waterproofing layer to shield it from weather and temperature extremes.

Determining the Placement of the Roof Membrane

The relationship between the roof membrane and insulation is a key design choice in a roof enclosure system. Where the insulation sits depends heavily on the membrane’s performance characteristics and the slope of the roof. Some membranes can tolerate minimal slopes, while others require steeper slopes to shed water effectively. If a membrane is designed to handle light foot traffic, can resist constant UV exposure, must cover a very large area where steep sloping is impractical, or snow loading isn't of concern, insulation may be placed under the low slope membrane. If the membrane needs to last longer by being protected from UV, foot traffic, and other potential damage, the insulation and overburden may be placed over the membrane. This placement choice directly affects how the roof enclosure system manages moisture, protects materials, and meets long-term performance goals.

Conventional vs. Inverted (PRMA) Assemblies

In conventional roof assemblies, the membrane is placed on top of the insulation layer, with the insulation below the membrane. These types of roof assemblies are the ones used most prevalently in the industry. Protected Roof Membrane Assemblies (PRMA) change that order with the insulation placed above the waterproofing layer. This design shields the membrane from UV exposure and reduces thermal cycling, which can extend the service life of the roof and lower long-term maintenance needs.

Because the insulation is above the membrane in PRMA, like putting your raincoat under an insulated vest instead of over it, it must resist moisture absorption, maintain thermal performance when wet, and provide high compressive strength to support overburden materials. In the U.S., extruded polystyrene (XPS) is the only material choice for this application.

How Insulation Layering Differs Above vs. Below the Membrane

In assemblies where insulation is placed above the membrane (PRMA), it must be protected from sunlight and weather. Pavers, vegetation, or other overburden provide this protection while also functioning as ballast. When insulation is placed below the membrane, the membrane itself provides protection; however, the insulation must be compatible with the expected loads and moisture conditions.

Ballast Types and Their Impact on Insulation Selection

Ballast is a heavy material, such as stone or pavers, used to hold roofing components in place. Stone ballast is less common today due to wind concerns. Pavers are more common for amenity decks because they provide a stable walking surface, while vegetation and topping slabs are used in designs that require functional or aesthetic coverage. The choice of ballast should be matched with insulation that can support the intended load and maintain performance over time.

3. Evaluate the Roof Performance Attributes

Selecting commercial roof insulation involves more than meeting basic code requirements. Key performance attributes such as thermal efficiency, fire resistance, structural strength, wind performance, and durability in extreme conditions all play a role in ensuring the roof performs as intended for the life of the building.

R-value and Thermal Performance

This attribute indicates the insulation’s ability to resist heat flow and maintain desired indoor temperatures. Higher R-values generally provide better thermal control but must be matched to the climate zone and code requirements for the project.

Fire Resistance

Fire resistance refers to meeting required fire tests, such as ASTM E-108 for surface flame spread, ASTM E-119 for structural fire rating, or NFPA 276 for fire from inside the building. The specific tests required depend on factors such as roof type, deck material, and local codes.

Compressive Strength and Walkability

Compressive strength measures the insulation’s capacity to resist equipment loads, foot traffic, or overburden materials without compromising its performance.

Wind Uplift Resistance and Structural Demands

Wind uplift resistance involves ensuring the roof system can remain in place during high winds or storms. FM Global’s RoofNav and UL listings are often used to determine fastening patterns, adhesives, or attachment methods that will meet the required uplift ratings with a specific configuration of membranes, decks, and insulations.

Behavior in High-exposure Conditions

High-exposure conditions, such as solar heat gain, freeze-thaw cycles, and thermal cycling, can place stress on roof insulation. The material must be able to withstand expansion, contraction, and weathering while working in tandem with the membrane and other roof components to maintain long-term performance.

4. Account for Climate and Regional Code Requirements

Roof insulation requirements are shaped by climate zone and the codes adopted in a specific jurisdiction. National standards often start with ASHRAE 90.1 protocol (the American Society of Heating, Refrigerating, and Air-Conditioning Engineers), which sets energy efficiency targets based on factors like building envelope performance, HVAC sizing, and cost-to-benefit analysis for insulation. These standards are often incorporated into the International Energy Conservation Code (IECC) by the International Code Council. Still, some jurisdictions adopt ASHRAE directly or modify the requirements at the state or local level.

Within the IECC, insulation requirements vary depending on whether it is installed entirely above the roof deck or within other parts of the assembly. Climate zones are mapped by region, with each zone assigned a minimum R-value. For example, a low-slope roof in a warm zone might only require 3" of XPS insulation (1 layer) while a roof in a colder zone requires 6" ( 2 layers) of XPS insulation, while a roof in a cold zone could need much higher levels to meet code. While wet conditions can occur in many climates, coastal regions may call for insulation that resists salt or chemical exposure, and areas with large seasonal temperature swings should account for long-term durability.

5. Consider Project Type and Building Use

The type of project, whether it is new construction, a roof replacement, or a retrofit, can strongly influence insulation decisions. Historic buildings bring unique challenges, as preservation requirements may limit changes to visible roof elements or materials. Building use is another critical factor. For example, data centers may need insulation with higher thermal stability to protect equipment, and high-rises must account for elevated wind loads.

6. Understand the Options for Insulation Material

Commercial roof insulation comes in several material options, each with its own strengths, limitations, and best-fit applications. The choice depends on factors like roof type, assembly design, climate zone, budget, and performance priorities.

Types of Commercial Roof Insulation Material:

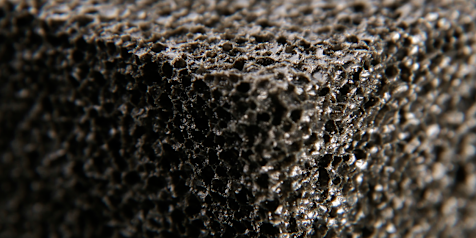

XPS (Extruded Polystyrene)

XPS offers strong water resistance, consistent thermal performance, and high compressive strength, making it ideal for protected roof membrane assemblies (PRMA) where the insulation is exposed to moisture. FOAMULAR® NGX® is a newer formulation of XPS that delivers the same performance as traditional XPS while using a lower global warming potential (GWP) blowing agent to meet evolving sustainability and code requirements for roofs.

Polyiso (Polyisocyanurate)

Polyiso is the most common insulation for conventional low-slope commercial roofs. It offers a high R-value per inch and is lightweight, but its thermal performance can drop at low temperatures, and it relies on composite facers for properties such as puncture and moisture resistance.

Fiberglass

Fiberglass insulation is non-combustible, offers good acoustic performance, and resists moisture absorption. However, this board insulation is less common in fully exposed applications due to lower compressive strength.

Cellular Glass

Cellular glass insulation provides excellent moisture resistance, vapor impermeability, and dimensional stability, making it a good choice for chemically resistant or high-moisture environments. It is available in smaller units and is non-combustible (unfaced) but has a lower R-value per inch and is more expensive than some other product types.

Spray Foam

Spray Polyurethane Foam creates a seamless insulation and air barrier in one application, making it useful for continuous insulation, complex roof geometries, or retrofit projects. Spray foam insulation requires a protective coating and is more common in certain regional markets like the Southwest.

Single-Ply vs. Fluid-Applied Roof Enclosures

The right material choice also depends on how the insulation will interact with the roof membrane and enclosure design. Different assemblies, such as single-ply membrane systems and fluid-applied membrane systems, place unique demands on insulation in terms of compressive strength, moisture resistance, and compatibility with adhesives or attachment methods.

Single-ply assemblies, often used on metal decks, often rely on mechanically attached or adhered sheets that require insulation compatible with the membrane and fastening method. Fluid-applied enclosures, more common on concrete decks, create a continuous waterproofing layer and may be part of protected roof membrane assemblies (PRMA). These often call for insulation with high compressive strength, moisture resistance, and, in some cases, integrated drainage channels to manage water beneath overburden such as stone, pavers, or vegetation.

7. Plan for Installation and Future Trends

Choosing the wrong insulation material or overlooking key compatibility checks can undermine a roof’s performance and shorten its service life. Some mistakes lead to code violations, while others cause early material failure that could have been avoided with proper planning and communication between manufacturers, designers, and contractors.

Common Mistakes in Selecting Commercial Roof Insulation

- Not verifying assembly requirements: Failing to confirm that insulation and other components meet tested and listed assembly criteria, which can result in code violations or roof failure after wind or fire events.

- Using incompatible adhesives: Adhesive formulations may change without notice, sometimes causing chemical reactions that damage insulation. Coordination with both the membrane and insulation manufacturers is essential.

- Improper handling during installation: Certain types of commercial roof insulation, like XPS, EPS, and polyiso, can warp when left exposed to high heat or direct sunlight before being covered. This risk increases in urban heat islands, such as high-rise vegetative roof projects surrounded by reflective glass buildings, where heat and light are intensified. Avoid staging insulation days in advance or covering it with clear plastic, which can trap heat.

Looking Ahead: Vegetative Roofs, Sustainability, and Industry Trends

Innovation in insulation is being driven by the growth of vegetative roofs and the broader push for sustainability. Materials like FOAMULAR® NGX®, which uses a low product global warming potential (GWP) blowing agent, align with post–Montreal Protocol environmental goals while maintaining thermal and structural performance. Manufacturers are responding with expanded lines of tested assemblies, clear fire documentation, and engineering judgments to address complex designs and unique installation conditions.

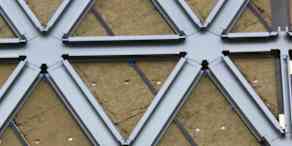

Vegetative Roof Assemblies (VRA) are roof systems designed to support plant growth and deliver long-term environmental and functional benefits. VRAs can help manage stormwater, moderate rooftop temperatures, reduce the urban heat island effect felt in cities from asphalt roads and concrete skyscrapers, and assist with improving air quality. These roof assemblies also create usable landscaped areas, such as terraces, gardens, or walkways. When specifying insulation for VRAs, materials must combine high compressive strength with moisture resistance to perform reliably under heavy overburden and in wet conditions. Some solutions incorporate insulation with integrated drainage channels on the underside, paired with waterproofing membranes and concrete decks, to help manage water flow while maintaining thermal performance. Extruded polystyrene (XPS) is selected for these applications and is recommended in industry guidelines, including those from the National Roofing Contractors Association.

Solar panel installations are becoming more common for roof applications, adding new considerations for commercial building insulation selection. The panels can create shaded zones that change temperature patterns across the roof, while concentrating heat in certain areas. In some cases, fire testing and code compliance requirements may also change when these panel systems are installed. As building codes and environmental targets evolve, commercial roof insulation types will continue to be shaped by a balance of performance, durability, budget, and sustainability goals. Designers and contractors who stay informed on tested assemblies, material innovations, and emerging regulations will be best positioned to create roof systems that meet both current demands and future expectations.

Choosing the Right Insulation for Your Commercial Roof

In commercial roofing, insulation selection is part of a system-wide design decision. Commercial roof insulation should be specified with the entire roof system in mind, rather than as a separate product. Designers, contractors, and specifiers must weigh numerous factors, including system compatibility, code compliance, durability, and environmental exposure, to select the proper insulating material for the project.

Proven products like FOAMULAR® NGX® can simplify the process by delivering reliable performance in both conventional and PRMA assemblies while supporting sustainability goals. When selected as part of a coordinated roof design, insulation helps the roof perform as intended throughout its service life. The best results of commercial building roof insulation come from viewing the roof as a whole system rather than separate layers and making your selection based on this broader viewpoint.

Related Articles

Sustainability • Commercial • BlogRegulations and roofs: Next generation insulation and sustainable VRA design

Sustainability • Commercial • BlogRedesigning insulation for improved sustainability, carbon footprint

Sustainability • Commercial • BlogBreaking Down the Claims: A Look at Product Labels and Certifications

Sustainability • Commercial • BlogReviewing the ins and outs of the LEED program

Fire • Commercial • BlogMineral Wool Wall Insulation & Fire Safety

Moisture • Commercial • Blog7 Key Factors for Selecting Commercial Roof Insulation

Fire • Commercial • BlogStone Wool Versus Slag Wool Insulation

Fire • Industrial • WebinarLNG Pool Fire Suppression & Cryogenic Liquid Spill Protection

Fire • Commercial • BlogThermafiber®, the Workhorse in Perimeter Fire Containment, Celebrates 90 Years

Fire • Commercial • BlogFAQs About Thermafiber® Mineral Wool Insulation

Fire • Industrial • BlogCombustible Liquids in Insulation

Thermal • Industrial • BlogKEY CONSIDERATIONS IN DESIGNING DIRECT BURIAL INSULATION SYSTEMS

Fire • Industrial • BlogThe Behavior of Industrial Insulation in Case of Fire

Moisture • Industrial • BlogSpecifying Insulation to Support Longevity in Chilled Water Systems

Moisture • Industrial • WebinarChilled Water Systems Webinar

Fire • Industrial • WebinarPassive Fire Protection Systems Webinar

Fire • Industrial • BlogMitigating LNG pool fires using passive systems

Fire • Industrial • BlogFire testing takeaways to consider when selecting insulation for fire protection

Fire • Commercial • BlogBalancing life safety, installation efficiency and design flexibility

Moisture • Industrial • BlogDesigning chilled water insulation systems to mitigate regional conditions

Moisture • Industrial • BlogUsing Cellular Glass Insulation to Mitigate Corrosion Under Insulation (CUI)

Moisture • Commercial • BlogOpinions and opportunities in building for resilience

Moisture • Commercial • BlogVersatile VRAs: The role of XPS in VRA function and design

Moisture • Mechanical • BlogDesign considerations for district energy insulation systems

Sustainability • Mechanical • BlogMaking use of Delta T: Reducing industrial energy emissions with mechanical insulation

Moisture • Industrial • BlogConsiderations for insulating district energy systems

Fire • Commercial • BlogNavigating Six Special Conditions in Perimeter Fire Containment System Design

Moisture • Commercial • Blog3 Benefits of Mineral Wool Continuous Insulation (ci) for Moisture Management

Moisture • Mechanical • BlogFive mechanical insulation considerations for healthcare facilities

Fire • Commercial • BlogDismantling 5 Common Perimeter Fire Containment Misconceptions

Thermal • Mechanical • BlogLabor saving features to reduce pipe insulation installation time

Fire • Mechanical • BlogProtecting life safety in plenum spaces

Acoustics • Mechanical • BlogAcoustic insulation solutions for industrial pipe applications

Moisture • Commercial • BlogUsing WUFI® as a moisture management design tool

Fire • Commercial • Blog3 Components of Fire Protection for Balanced Life Safety

Fire • Commercial • BlogSix Critical Components of a Listed Perimeter Fire Containment Assembly

Moisture • Commercial • BlogDurable Design: Using Technology to Achieve Expected Building Service Lifespans

Fire • Commercial • BlogUnderstanding the SAFETY Act: Using perimeter fire containment systems to reduce liability

Fire • Commercial • BlogSix Critical Components of Engineering Judgments for PFC Systems

Jump to a Solution Suite

Jump to a Solution Suite